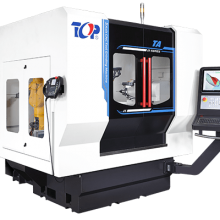

The TA-5 CNC tool grinder features highly rigid structural design and is aimed at grinding medium-sized and large-sized HSS and carbide material, especially at applications of aerospace and automobile.

It is widely used for standard tools, special tools, re-grinding, batch grinding, and mixed batch grinding, etc. high power output spindle and unmanned operation, while it remains stability and precision during the grinding process.

1. Horizontal structure with high rigidity.

2. Built-in spindle HSK-50E.

3. 3D tool probe/grinding wheel probe, automatically detects changes to improve machining accuracy.

4. Workhead A axis spindle taper is BT50,driven by direct drive motor.

5. Built-in spindle HSK-50E and grinding wheel automatic exchange system with 4 sets of grinding wheels for exchange; each group of 3 wheels with maximum wheel diameter of Ø150 mm and the longest wheel position of 200 mm.

6. Optional Swiss STAUBLI TX2-60 robot loader with high degree of freedom and flexibility.

7. The internal storage bin of the optional machine accommodates 4 workpieces with a diameter of Ø3 to 16 mm.

Built-in Spindle

Spindle Type is HSK-50E

High Rigidity

High Precision

High Power and High Torque

Low Vibration

TA-5 is equipped with 4 sets of grinding wheels, with up to 3 wheels/set, Spindle type is HSK-50E.

For changing the roughing, finishing and polishing wheels, Choose appropriate cutting oil and filter equipment for grinding of different materials, such as tungsten steel, HSS, and stainless steel.

Direct Drive Motor

Workhead Taper is BT50.

The Workpiece is Quickly Clamped by the Force of Air Pressure.

The Concentricity is Within 2 um.

Automatically measure important tool parameters, and perfectly position tool in the shortest time.

Provide accurate, repeatable geometric data, and measure front position, back position and grinding wheel contour radius.

Flexium+ has new and enhanced features, new panels, a new HMI, an enhanced servo bus, enhanced drives and simplified connectivity.

With NUMROTOplus®, a wide range of tools can be manufactured and resharpened, Each tool detail can be adjusted to suit individual needs, an exceptional variety of programs with a built-in database for tools, technology and grinding wheel packages, Auxiliary pictures for all parameter settings, displaying true to scale tool dimensions.

The 2D simulation is an integral part of NUMROTOplus®,

all grinding operations can be simulated on the PC using the 2D simulation, With the integration in the NUMROTO software of 3D tool simulation with grinding process animation and collision monitoring with 3D machine simulation.

NUMROTO Draw (opt. )

After entering all geometry parameters a dimensioned projection drawing can be created automatically, which are taken as true-to-scale color graphic image or DXF drawing from the 3D simulation.

SPC8 (for Collet Ø3-Ø8 mm)

Ø6 mm

SPC16 (for Collet Ø9-Ø16 mm)

SPC25 (for Collet Ø20,Ø25 mm)

Ø3, Ø4, Ø8, Ø10, Ø12, Ø16,Ø20,Ø25 mm

Send Inquiry to This Supplier

You May Also Like

-

Ta-5 CNC Tool & Cutter GrindeUS$ 276029MOQ: 1 Case

-

Cm-a Monaset Tool GrinderUS$ 48900MOQ: 1 Unit

-

HS-16 Hob Sharpening MachineUS$ 48900MOQ: 1 Unit

-

Fedek Gt 326 Bar FeederUS$ 6500MOQ: 1 Case

-

Ta-5 Plus CNC Tool GrinderUS$ 276029MOQ: 1 Case

-

Fedek Bar Automatic Feeding MachineUS$ 6200 - 7200MOQ: 1 Case

-

M-40 Universal Cutter & Tool GrinderUS$ 23300MOQ: 1 Case

-

Fedek, Gt342automatic Bar Feeding System Forfixed and Sliding Headstock LathesUS$ 13000 - 13200MOQ: 1 Case

-

Gt 342bar Feeding SystemsUS$ 12800MOQ: 1 Case

-

Gt 342bar Feeding SystemsUS$ 12800MOQ: 1 Case