Application Scenarios for Polyurethane Wheels in Military Turnover Vehicles

Polyurethane wheels are widely used in the military industry, suitable for heavy equipment handling, precision instrument transportation, high-temperature operation, high-frequency turnover, and adaptability to unusual terrain. They offer high load-bearing capacity, low wear, shock absorption, and high-temperature, oil, and wear resistance, meeting the stringent requirements of military enterprises for turnover wheels and improving transportation efficiency and equipment safety.

1. Heavy Equipment Handling Scenario

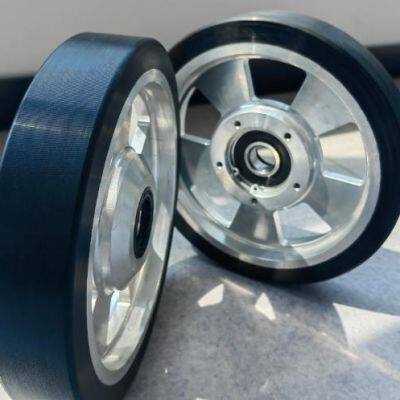

Military enterprises often need to transport precision instruments and heavy weapon components. Polyurethane wheels offer high load capacity (≥ 1.5 tons per wheel) and low wear. For example, Filson's 450*85*30 polyurethane wheels, equipped with a 45# steel wheel core and deep-groove ball bearings, can stably carry loads exceeding 1.5 tons on complex surfaces (such as gravel and railroad tracks), eliminating the deformation and excessive noise associated with traditional steel wheels.

2. Precision Instrument Transport

The shock-absorbing properties of polyurethane wheels are crucial for transporting precision equipment such as missiles and radars. Their elastic modulus remains stable from -20°C to 110°C, absorbing bumps and shocks to ensure equipment is transported without displacement or vibration damage. For example, one military enterprise saw a 70% reduction in damage to precision instruments after using polyurethane-wheeled turnover vehicles.

3. High-Temperature Operations

Military production often involves high-temperature workshops (such as casting and heat treatment). Polyurethane wheels withstand temperatures up to 110°C and are oil- and chemical-resistant, allowing for long-term use in environments with engine oil and hydraulic fluids. They offer an alternative to traditional rubber wheels, which are susceptible to aging and burning.

4. High-Frequency Operations

In environments where ammunition and spare parts are frequently moved in and out of storage, the wear resistance of polyurethane wheels (with a wear coefficient 3-5 times that of ordinary rubber) reduces the frequency of wheel replacement. For example, a military warehouse using polyurethane-wheeled turnover vehicles reduced annual equipment maintenance costs by 40%, and the lifespan of a single wheel can reach 7-10 years.

5. Special Terrain Adaptation

For field combat equipment transportation, polyurethane wheels can be customized (such as thickened rubber coatings and reinforced ribs) to adapt to complex terrain such as mud and gravel, while maintaining low noise levels to minimize exposure.

Send Inquiry to This Supplier

You May Also Like

-

Characteristics and Applications of Cast Polyamide WheelsUS$ 95 - 120MOQ: 3 Sets

-

Submarine Cable Bend RestrictorsUS$ 1000 - 1200MOQ: 1 Piece

-

Polyurethane Submarine Cable Protective TubeUS$ 98 - 120MOQ: 1 Piece

-

DRS Wheel Block System With Spheroidal-Graphite Cast Iron (GGG 70)US$ 1250 - 1460MOQ: 1 Combo

-

Heavy-Duty Steel Core Polyurethane Wheels for High-Strength Industrial TransportationUS$ 95 - 120MOQ: 1 Unit

-

Cable Bend Protection for the Offshore Energy IndustryUS$ 950 - 1200MOQ: 1 Set

-

Demag DRS Wheel Block for Transfer Rail CartsUS$ 1250 - 1400MOQ: 1 Combo

-

High-Capacity Polyurethane Drive Wheel for StackersUS$ 95 - 120MOQ: 3 Combos

-

High Bearing Capacity PU Forklift WheelUS$ 95 - 120MOQ: 3 Pieces

-

Knife Gate Valve for Mining and Coal Washing - Suitable for Ash Slag and Solid Particles With Heavy-Duty Cast Steel BodyNegotiableMOQ: 1 Set