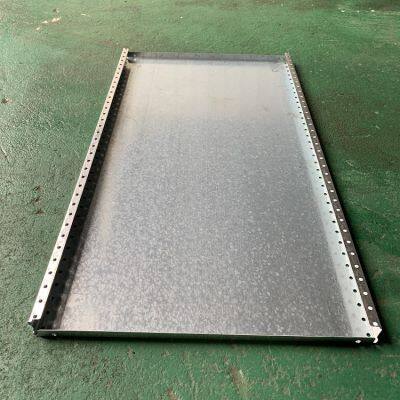

Full Set of Shelf Panels Racks Column Cold Roll Forming Machine

1. Good quality: We have a professional designer and experienced engineer team and the raw material and accessories we use are

good.

2. Good service: we provide the technical support for whole life of our machines.

3. Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic

and hydraulic parts in the line except for the easy-worn parts.

4. Easy operation: All machine controlling by PLC computer controlling system.

5. Elegant appearance: Protect the machine from rust and the painted color can be customized

6. Reasonable price: We offer the best price in our industry.

Technical Specifications of the storage shelf cold roll forming machine

Send Inquiry to This Supplier

You May Also Like

-

Advanced Technology Automatic Roof Batten Roll Forming Machine Omega Profile Core Motor Pump for Furring Channel MakingUS$ 9800 - 11250MOQ: 1 Piece

-

Factory Direct Special-Shaped Tile Pressing Roll Forming Machine Low Price for Roof Use Essential Engine Gear Bearing Motor PumpUS$ 6200MOQ: 1 Piece

-

High Performance CZ Purlin Forming Machine Steel Frame and Purlin Production LineUS$ 23800 - 27800MOQ: 1 Piece

-

New Arrival Soffit Panel Roll Forming Machine Metal Ceiling Panel Roll Forming Machine With Automatic CutterUS$ 17500 - 19500MOQ: 1 Piece

-

High Speed Scaffolding Plank Making Equipment Machine Walk Board Sheet Scaffold Plank MachineUS$ 27800 - 29800MOQ: 1 Piece

-

Hot Selling Self Click Lock Roof Roll Forming Machine Standing Seam Roll Forming Machine for Roofing MachineryUS$ 7600 - 8500MOQ: 1 Piece

-

Fast Delivery Standing Seam Roofing Panel Roll Forming MachineUS$ 8300 - 10500MOQ: 1 Piece

-

Steel Ridge Cap Roll Forming Machine 840 IBR Roof Sheet Use PLC Control System for Tile Making IndustriesUS$ 6800 - 7500MOQ: 1 Piece

-

High-Speed Automatic C Z Purlin Roll Forming Machine Multi-Function Full Automatic Steel Frame Featuring Motor Bearing PLCUS$ 18500 - 21500MOQ: 1 Piece

-

Low Cost Channel C/Z Machine Fully Automatic Cold Steel Profile C/Z Purlin Roll Forming MachineryUS$ 10000 - 12000MOQ: 1 Piece