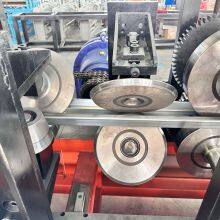

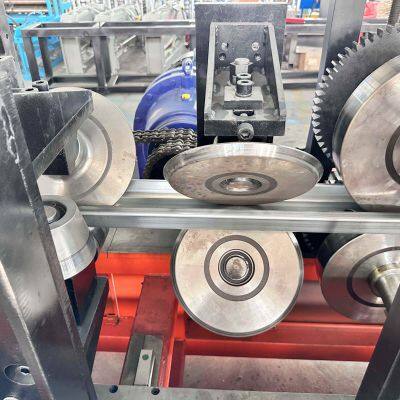

High Performance CZ Purlin Forming Machine Steel Frame and Purlin Production Line

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost.

4.Infinite sizing(any size within machine range),help to save material.

5.Optional Punch hole at any position of purlin web side and flange side.

Knife made of steel.

Automatic activation.

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 15 to 30 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and otherparts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.

Send Inquiry to This Supplier

You May Also Like

-

Steel Ridge Cap Roll Forming Machine 840 IBR Roof Sheet Use PLC Control System for Tile Making IndustriesUS$ 6800 - 7500MOQ: 1 Piece

-

Low Cost Channel C/Z Machine Fully Automatic Cold Steel Profile C/Z Purlin Roll Forming MachineryUS$ 10000 - 12000MOQ: 1 Piece

-

Hot Sale Square Pipe Making Machine Steel Round Tube Mill Machine Forming Machine Pipe MillUS$ 20500 - 28500MOQ: 1 Piece

-

Competitive Price Storage Shelf Column Roll Forming Machine Supermarket Shelves Upright Rack Making MachineUS$ 23500 - 25000MOQ: 1 Piece

-

Cheap Price Roof Panel Roll Form Machine Deck Floor Roll Forming MachineUS$ 20500 - 23500MOQ: 1 Piece

-

High Frequency ERW Welded Tube Mill Stainless Steel Carbon Steel Pipe Making Machine With PLC Motor Pump Engine Core ComponentsUS$ 31500 - 32500MOQ: 1 Piece

-

Cheap Price Storage Rack Shelf Box Panel Making Machine Steel Storage Rack System Welding Box Beam Roll Forming MachineUS$ 8250 - 9850MOQ: 1 Piece

-

New Type Floor Decking Machine 36 Formlok 3" Deep Floor Deck Roll FormerUS$ 17000 - 18800MOQ: 1 Piece

-

High Quality Portable Seamless Roof Half-round Rain Water Gutter Cold Roll Forming MachineUS$ 6900 - 7800MOQ: 1 Piece

-

Metal Panel Highway Guardrail Fence Roll Forming Machine Road Steel Fence Making MachineUS$ 31500 - 36500MOQ: 1 Piece