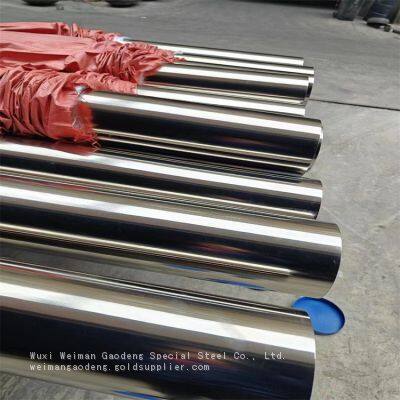

Automotive Grade 7" Diameter 409 Stainless Steel Pipe 0.6" Wall Thickness Stainless Steel Tube

Stainless Steel Pipe Product Description1. Product Parameter Table

Model | Diameter Range | Wall Thickness Range | Material | Standards Compliance | Surface Treatment | Length |

304 | 0.5"-12" | 0.05"-1.1" | Austenitic | ASTM A312, JIS G3459 | Pickling, Polishing, Mirror | 6m/12m |

316 | 0.75"-10" | 0.08"-1.0" | Austenitic | EN 10216-5, GB/T 14976 | Pickling, Brushing | 6m/12m |

430 | 1"-8" | 0.1"-0.75" | Ferritic | DIN 17458, ASTM A269 | Pickling, Matte | 6m/12m |

2205 Duplex | 2"-12" | 0.2"-1.1" | Duplex Steel | ASTM A790, JIS G3463 | Pickling, Sandblasting | 6m/12m |

310S | 4"-10" | 0.3"-0.9" | Austenitic | EN 10217-7, GB/T 13296 | Pickling | 6m/12m |

2. Product Details

Our stainless steel pipes are manufactured from high-quality raw materials (such as 304, 316, and duplex steel) through precision processes like cold-drawing and hot-rolling, ensuring dimensional accuracy (diameter tolerance ±0.02mm, wall thickness tolerance ±0.01mm). The pipe body is free from sand holes, cracks, or depressions, with a smooth, burr-free inner wall that reduces fluid transport resistance. Surface treatments support diverse customizations: pickling (enhances corrosion resistance), polishing (Ra≤0.8μm, suitable for sanitary scenarios), and mirror finishing (Ra≤0.08μm, meets decorative needs). Each batch undergoes eddy current testing, water pressure testing (no leakage under 10MPa), and composition analysis to ensure compliance with international standards.

3. Product Applications

Stainless steel pipes, with their excellent performance, are widely used in various fields:

Industrial sector: Chemical pipelines (transporting acid-alkali solutions), petroleum refining pipelines (resistant to high temperature and pressure), water treatment systems (corrosion resistance);

Construction sector: Curtain wall supports, handrails (304 material for rust resistance), water supply and drainage pipes (sanitary-grade 316L);

Medical sector: Medical device delivery tubes (17-4PH material, high strength and easy to clean);

Food industry: Food processing equipment pipelines (304 food-grade, compliant with FDA standards);

New energy sector: PV bracket connecting pipes (2205 duplex steel, strong weather resistance).

4. Product Performance Advantages

Corrosion Resistance: 316 and 316L contain molybdenum, resistant to chloride ion corrosion, suitable for coastal and chemical environments; 304 is ideal for general atmospheric and freshwater environments.

High-Temperature Resistance: 310S and 309S can work continuously at 800-1200℃, suitable for kilns and heat treatment equipment.

High Strength: 2205 duplex steel has a tensile strength ≥620MPa and yield strength ≥450MPa, 30% higher than ordinary austenitic steel.

Easy Machinability: 416 and 303 materials contain sulfur, offering excellent machinability for precision part processing; 301 has good ductility, suitable for bending and stamping.

Sanitary Performance: Polished inner walls of 304/316 pipes prevent bacterial growth, meeting food-grade and medical-grade requirements.

5. Company Introduction

We are a manufacturer with 15 years of experience in stainless steel pipe production. Our factory covers an area of 20,000㎡, equipped with 20 automated production lines, with an annual output of 5,000 tons. Certified by ISO9001 and ISO14001, our products are exported to over 30 countries in Europe, America, and Southeast Asia. We offer customization services: adjusting diameter, wall thickness, and length according to customer needs, with expedited production (delivery within 7 days). A professional quality inspection team monitors the entire process from raw material inbound to finished product outbound, ensuring stable quality for each batch. We provide a 1-year warranty, and our technical team is available 24/7 to answer installation and usage questions, offering customers a one-stop purchasing experience.

Send Inquiry to This Supplier

You May Also Like

-

0.5" Diameter Hardened 410 Stainless Steel Tube 0.05" Wall Thickness Stainless Steel PipeNegotiableMOQ: 1 Kilogram

-

Super Austenitic 12" Diameter 904L Stainless Steel Tube 1.1" Wall Thickness Stainless Steel PipeNegotiableMOQ: 1 Kilogram

-

Precipitation Hardening 1.75" Diameter 17-4PH Stainless Steel Pipe 0.11" Wall Thickness Stainless Steel TubeNegotiableMOQ: 1 Kilogram

-

Stabilized 2.25" Diameter TP347H Stainless Steel Pipe 0.18" Wall Thickness Stainless Steel TubeNegotiableMOQ: 1 Kilogram

-

904L Super Austenitic Stainless Steel Tube/pipe Factory Direct Sale High-quality Material Wholesale PriceNegotiableMOQ: 1 Ton

-

1.4435,724L,316LMOD Heavy Duty Stainless Steel Tubing for Industrial UseNegotiableMOQ: 1 Ton

-

Hot Cold Rolled SUS631/F51/2205/17- 4pH Stainless Steel Pipe TubeNegotiableMOQ: 1 Ton

-

High Quality SUS630/17-7PH Duplex Stainless Steel Tube Cheap PriceNegotiableMOQ: 1 Ton

-

Competitive Price S31803 Duplex Steel Stainless F52/S32950 Stainless Steel Seamless Pipe and TubeNegotiableMOQ: 1 Ton

-

S32760/S32750 Duplex Stainless Steel Pipe for Industrial UseNegotiableMOQ: 1 Ton