Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating temperature

0°C - 50°C

Humidity

5% - 95% (non - condensing)

Power Input

24V DC

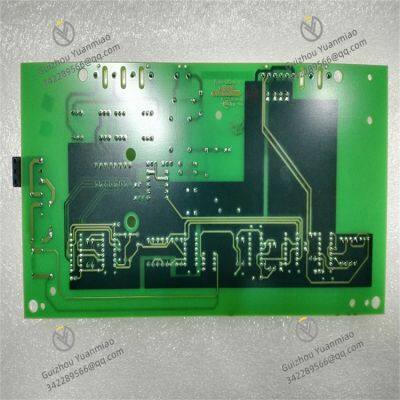

I. Overview

1336-PB-SP11A is a module with specific functions in Rockwell Automation's 1336 series, playing a key role in industrial automation systems. It is mainly used to cooperate with equipment such as 1336 series frequency converters, providing them with stable power support and related functional assistance to ensure the efficient and reliable operation of the entire industrial drive system.

This module has excellent compatibility with other equipment in the 1336 series and can be seamlessly integrated into various multi-motor drive systems. Through a series of circuit designs and technical means, it processes and converts the input power to provide accurately adapted power output for connected equipment, ensuring that all components in the system can work under appropriate electrical conditions. With its stable performance, excellent compatibility, and role in improving the overall operational stability of the system, 1336-PB-SP11A is widely used in various industrial fields, such as manufacturing production lines, material conveying systems, and automated processing equipment.

II. Technical Parameters

Input Parameters

Voltage range: It can adapt to a wide range of AC input voltages. The rated input voltage is usually 380V - 480V AC (three-phase), which can effectively be compatible with industrial universal three-phase AC power systems. It allows a certain degree of voltage fluctuation (the specific fluctuation range is subject to the product manual) to cope with complex power grid environments.

Frequency requirement: The input frequency range is 50Hz - 60Hz, which can adapt to common industrial power frequencies, ensuring stable operation in different regions and under different power supply conditions.

Output Parameters

Output voltage: It outputs a stable DC voltage to meet the DC power demand of connected equipment. Its rated DC output voltage is generally in the range of 540V DC - 650V DC (the specific value depends on the input voltage and internal circuit design, which can be referred to in the product manual), providing a reliable DC bus voltage for frequency converters and other equipment.

Output current: The rated output current can reach 11A (the "11" in the model "SP11A" is related to the rated current), which can provide sufficient power for medium-power equipment and meet the current demand when multiple small and medium-sized equipment are running simultaneously.

Power Level: Based on its output current and voltage, the rated power is usually within a certain range (the specific value is subject to the product manual), which can provide stable power support for multiple small and medium-sized frequency converters and other equipment to ensure the normal operation of the system.

Protection Characteristics

Overcurrent protection: When the output current exceeds a certain range of the rated value, the module will quickly activate the protection mechanism, automatically limit the output current or cut off the power supply to prevent damage to the module itself and connected equipment due to overload, ensuring the safe operation of the system.

Overvoltage protection: If it is detected that the output voltage rises abnormally and exceeds the set threshold (such as caused by power fluctuations or other abnormal situations), the module will immediately trigger overvoltage protection to avoid irreversible damage to the equipment caused by high voltage.

Undervoltage protection: When the input voltage is too low or internal module faults cause the output voltage to be lower than the specified value, the undervoltage protection function is activated to prevent the equipment from operating in a low-voltage state, which may affect performance or even cause damage.

Overheating protection: The module integrates a temperature monitoring component to monitor the working temperature of the module in real-time. Once the temperature exceeds the allowable range, overheating protection will automatically take effect by reducing the output power or stopping work, protecting the internal components of the module from high-temperature damage and extending the service life of the module.

Environmental Adaptability

Operating temperature: It can work normally in a temperature environment of 0°C - 50°C (the specific operating temperature range is subject to the product manual), adapting to the temperature conditions of most industrial sites, whether it is a high-temperature production workshop or a low-temperature storage environment, it can run stably.

Relative humidity: It can operate reliably in an environment with a relative humidity of 5% - 95% (non-condensing). Even in humid industrial environments such as textile mills and paper mills, its performance will not be affected by humidity.

Protection level: It generally has an IP20 protection level (installed indoors, avoiding direct contact with dust and liquids). In practical applications, it can be installed in a control cabinet, and the protection effect can be further improved by means of the control cabinet's protective measures to adapt to complex industrial on-site environments.

III. Functional Characteristics

Stable Power Output: 1336-PB-SP11A can provide extremely stable power output for connected equipment through carefully designed power conversion circuits and voltage stabilization technologies. The output voltage fluctuation is minimal, which effectively reduces the impact of voltage instability on the equipment, ensures the stability and reliability of multiple equipment when working together under a unified power supply, and improves the operational stability of the entire industrial drive system.

Efficient Energy Management: In systems where multiple devices work together, when some devices are in a braking state and generate regenerative energy, 1336-PB-SP11A can effectively manage this part of the energy. It can feed the regenerative energy back to the DC bus for use by other devices in the electric state, realizing energy recovery and sharing, greatly improving energy utilization efficiency, reducing the overall energy consumption of the system, and saving production costs for enterprises.

Simplified System Architecture: As a public power supply module, 1336-PB-SP11A can replace the independent power conversion units of multiple devices, significantly reducing the number of power supply devices in the system. This not only simplifies the wiring and layout of the system, reduces the difficulty of equipment installation and maintenance, but also reduces potential fault points and improves the overall reliability of the system.

Comprehensive Protection Mechanism: Multiple protection functions (overcurrent, overvoltage, undervoltage, overheating, etc.) provide all-round protection for the module and connected equipment. When an abnormal situation occurs in the system, the protection mechanism can respond quickly, cut off the power supply in time or take other protective measures, effectively reducing the risk of system failure, reducing the possibility of equipment damage, ensuring the continuity and safety of the production process, and extending the service life of the equipment.

Convenient Integration and Monitoring: The module is designed with standardized installation interfaces for convenient and quick installation in the control cabinet. When connecting with other equipment in the 1336 series, integration and commissioning can be completed only through specific interfaces and connections. Some models are also equipped with status indicators, which can intuitively display the operating status of the module, such as normal operation, fault alarm, etc., facilitating operators to keep abreast of the module's working conditions, quickly troubleshoot and solve faults, and improve equipment maintenance efficiency.

Adaptability to Multi-Equipment Collaborative Scenarios: The design of its output current and power fully considers the needs of multiple small and medium-sized equipment working simultaneously, and can well meet the power supply requirements of multi-equipment collaborative operation. Whether it is the synchronous operation of multiple conveyor motors in a production line or the collaborative work of multiple executive components in automated processing equipment, 1336-PB-SP11A can provide stable and reliable power support, ensuring the coordinated operation of various equipment and improving production efficiency.

IV. Application Scenarios

Manufacturing Production Lines: In manufacturing production lines such as automobile manufacturing and electronic equipment manufacturing, there are a large number of motor-driven equipment, such as conveyor chain motors, robot joint motors, and spindle motors of processing equipment. 1336-PB-SP11A can provide stable power for the frequency converters of these motors to realize the collaborative work between multiple motors. In automobile assembly lines, motors at multiple stations are powered by 1336-PB-SP11A, which can precisely control the motor speed and running time, ensure the accurate assembly of parts, and improve production efficiency and product quality. At the same time, its energy recovery function can feed back and utilize the energy generated during braking, reducing the energy consumption of the production line.

Material Conveying Systems: In material conveying scenarios such as logistics warehouses and port terminals, there are usually a large number of equipment such as conveyors, hoists, and stackers. The motors of these equipment need stable power supply to ensure efficient material conveying. 1336-PB-SP11A can provide reliable power for the frequency converters of these motors to ensure the stable operation of the conveying system. When the conveyor motor starts and stops frequently or decelerates, 1336-PB-SP11A can recover the braking energy and supply it to other equipment, improving energy utilization efficiency and reducing operating costs.

Automated Processing Equipment: In automated processing equipment such as CNC machine tools and automated production lines, each axis drive motor requires precise speed and position control to ensure processing accuracy. 1336-PB-SP11A provides stable power for the frequency converters of these motors, ensuring stable operation of the motors and meeting the high-precision control requirements of processing equipment. At the same time, its comprehensive protection mechanism can effectively protect the equipment from the impact of power supply abnormalities during complex processing, improve the reliability and stability of the equipment, and reduce the impact of equipment failures on the production schedule.