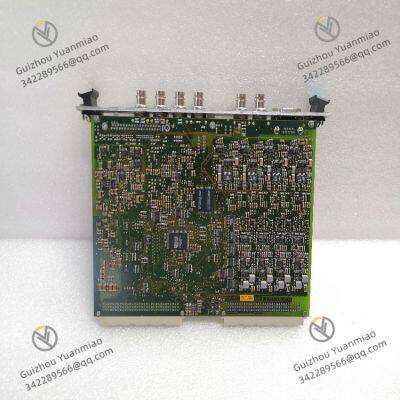

Vibro-meter 200-510-041-021 200-510-111-021 VM600 MPC4 is a powerful and advanced component of a vibration monitoring and analysis system. In the industrial field, it plays a crucial role in ensuring the stable operation of key mechanical equipment. With its precise data collection and processing capabilities, reliable system performance, and wide applicability, it has become a valuable assistant for equipment condition monitoring in numerous industries.

I. Core Functions

(1) Accurate Vibration Data Collection

Multi-channel synchronous acquisition: The MPC4 module is equipped with 4 input channels, enabling synchronous collection of vibration data from multiple measurement points. In the monitoring of large rotating machinery such as steam turbines and compressors, it can simultaneously conduct real-time monitoring of vibrations at multiple key parts (such as bearing housings and shaft necks), comprehensively reflecting the operating status of the equipment and providing a rich data foundation for accurate fault diagnosis. Through comprehensive analysis of vibration data from different parts, potential fault sources such as bearing wear and rotor imbalance can be quickly identified.

Broadband signal capture: Its frequency response range covers 0-20kHz, which can effectively capture various vibration signals from low to high frequencies. It can accurately collect both low-frequency vibrations during normal equipment operation and high-frequency impact signals that may occur when faults occur. For example, in the monitoring of gearboxes, the MPC4 module can clearly capture the low-frequency vibrations generated during normal meshing and the high-frequency impact signals caused by gear cracks or wear, providing a basis for early fault warning.

(2) Efficient Data Processing and Analysis

Advanced signal filtering technology: It has a built-in advanced signal filtering algorithm, which can denoise the collected original vibration signals, remove environmental interference and noise signals, and retain real and effective equipment vibration characteristic signals. In complex industrial environments, such as steel plants and cement plants with a large amount of electromagnetic interference and mechanical noise, filtering can improve the signal-to-noise ratio, making the analysis results more accurate and reliable. For example, in motor operation monitoring, it can effectively filter out interference signals from power grid fluctuations and surrounding equipment, highlighting the motor's own vibration characteristics.

High-speed data processing capability: It has high-speed data processing capability with a maximum sampling rate of up to 51.2kHz, which can quickly conduct real-time analysis of the collected vibration data. When the equipment operating status changes rapidly, such as during start-up, shutdown, or sudden load changes, it can timely capture the dynamic changes of vibration signals, providing timely and accurate data support for the safe start-up/shutdown of equipment and adjustment of operating status. For example, during the start-up of a fan, through rapid analysis of vibration data, it can be judged whether the fan has abnormal vibration, ensuring the smooth progress of the start-up process.

(3) Flexible Communication and System Integration

Support for multiple communication interfaces: It supports Ethernet and USB communication interfaces, facilitating data interaction with upper computer control systems, data storage devices, and other monitoring equipment. Through the Ethernet interface, remote data transmission and remote monitoring can be realized. Technicians can obtain real-time vibration data of equipment in the control center and conduct remote diagnosis and analysis. At the same time, the USB interface can be used for rapid on-site data backup and convenient setting of equipment parameters, improving the efficiency of on-site maintenance and debugging. For example, in the equipment monitoring system of smart factories, the MPC4 module transmits data to the central server through Ethernet, realizing centralized management of the equipment status of the entire factory.

Easy system integration: As part of the Vibro-meter VM600 monitoring system, it can be seamlessly integrated with other components of the system (such as sensors, signal conditioners, and controllers) to form a complete equipment condition monitoring solution. Meanwhile, its standardized interfaces and communication protocols make it easy to integrate with third-party control systems, and personalized monitoring systems can be flexibly built according to the actual needs of users. For example, in the automation control system of petrochemical enterprises, the MPC4 module can be integrated with the enterprise's existing DCS system, integrating vibration monitoring data into the monitoring system of the entire production process.

(4) Comprehensive Equipment Protection and Early Warning

Real-time status monitoring and evaluation: It continuously monitors the vibration status of equipment in real-time, and evaluates the operating status of the equipment in real-time according to preset thresholds and analysis models. Once the vibration parameters exceed the normal range, the system immediately sends an early warning signal, indicating that the equipment may have potential faults. For example, during the operation of a water pump, when the vibration amplitude exceeds the set safety threshold, the MPC4 module can send alarm information to the upper computer through the communication interface, reminding operators to check the equipment in time to prevent the fault from expanding.

Fault diagnosis and prediction function: With strong data processing and analysis capabilities, it conducts in-depth mining and analysis of the collected vibration data, and can identify various common equipment fault modes such as imbalance, misalignment, and bearing faults. It can also predict the development trend of equipment faults through trend analysis. In the monitoring of generators in the power industry, through the analysis of long-term vibration data, the remaining service life of bearings can be predicted, maintenance plans can be arranged in advance, the risk of sudden equipment failures can be reduced, and the reliability and availability of equipment can be improved.

II. Hardware Characteristics

(1) Rugged Industrial-grade Design

Wide temperature operating range: It adopts industrial-grade components and design schemes, and can work stably in an ambient temperature range of -10°C to 60°C. Whether in cold outdoor industrial facilities such as wind turbines or high-temperature industrial production workshops such as equipment monitoring near metallurgical furnaces, it can operate reliably, ensuring that vibration monitoring is not affected by ambient temperature.

High protection and anti-interference performance: It has good dustproof and moisture-proof performance, with a certain level of protection, and can adapt to harsh industrial environments such as dusty and humid conditions. At the same time, it has excellent anti-electromagnetic interference capability, which can resist complex electromagnetic noise interference in industrial sites, ensuring the accuracy and stability of the collected vibration signals. In industrial environments with a large number of strong electromagnetic interference sources such as frequency converters and electric welders, such as automobile manufacturing plants, it can effectively avoid the impact of interference on monitoring data.

(2) Compact Structure and Convenient Installation

Modular compact design: The MPC4 module adopts a modular design with a compact structure, small size (e.g., 100mm x 50mm x 30mm), and light weight (about 100g), making it easy to install in equipment control cabinets or monitoring sites with limited space. In the monitoring of small mechanical equipment and occasions with strict requirements on installation space, its compact design advantage is particularly prominent. It can be flexibly installed near key parts of the equipment to reduce signal transmission loss.

Standardized installation interfaces: It is equipped with standardized installation interfaces and terminals, and the installation method is simple and convenient. Technicians can quickly complete the installation and wiring work according to the installation manual. When modifying on-site equipment or adding new monitoring points, it can greatly shorten the installation and commissioning time, improve work efficiency, and reduce installation costs.

(3) Stable and Reliable Power Supply

Wide-voltage DC power supply: It supports 24V DC power supply and has a certain wide-voltage adaptability, which can work normally within a certain voltage fluctuation range. In cases where the power supply at industrial sites has certain fluctuations, such as industrial facilities in remote areas with unstable power supply, it can ensure the stable operation of the module and the continuity of vibration monitoring work.

Power protection functions: It has overvoltage, overcurrent, and short-circuit protection functions. When there is an abnormal power supply, it can effectively protect the internal circuit of the module from damage, improve the safety and reliability of the equipment, and extend the service life of the module. In case of wrong power wiring or instantaneous impact of external power supply, it can automatically cut off the abnormal power supply to avoid damage to the module due to power failure.

III. Application Fields

(1) Energy and Power Industry

Power generation equipment monitoring: In various power generation facilities such as thermal power, hydropower, and wind power generation, it is used to monitor the vibration status of key equipment such as steam turbines, generators, water turbines, and fans. Through real-time monitoring of vibration data, potential faults of equipment such as steam turbine blade damage, generator rotor imbalance, and fan bearing faults can be found in time, ensuring the safe and stable operation of power generation equipment, improving power generation efficiency, and reducing downtime and economic losses caused by equipment faults.

Power transmission and distribution equipment monitoring: Vibration monitoring of power transmission and distribution equipment such as transformers and high-voltage switches can assist in judging the operating status of the equipment. For example, problems such as loose iron cores inside transformers and poor contact of high-voltage switch contacts can be early warned through changes in vibration signals, ensuring the reliability and stability of power transmission.

(2) Petrochemical Industry

Monitoring of key equipment in production plants: In production plants such as petroleum refining and chemical synthesis, it conducts vibration monitoring of key equipment such as compressors, pumps, and centrifuges. These devices are prone to mechanical failures during long-term high-load operation. Through the monitoring of the MPC4 module, abnormal vibrations of the equipment can be found in time, and maintenance measures can be taken in advance to prevent production accidents caused by equipment failures and ensure the continuity and safety of the chemical production process.

Vibration monitoring of pipeline systems: Vibration monitoring of chemical pipeline systems can timely detect abnormal vibrations caused by pipeline resonance and fluid impact, avoid safety hazards such as pipeline rupture and leakage, and ensure the safe operation of chemical pipeline systems.

(3) Manufacturing Industry

Machine tool equipment monitoring: In the mechanical processing industry, vibration monitoring of machine tools such as CNC machine tools and machining centers helps to grasp the operating status of machine tools in real-time, timely find problems such as tool wear and spindle imbalance, ensure processing accuracy and product quality, and improve the service life and production efficiency of machine tools.

Monitoring of automated production line equipment: In automated production lines such as automobile manufacturing and electronic manufacturing, vibration monitoring of conveying equipment, assembly robots, packaging machinery, and other equipment can timely find potential equipment faults, ensure the stable operation of the production line, reduce production line shutdowns caused by equipment faults, and improve production efficiency and enterprise economic benefits.