Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating temperature

-40°C to +85°C

Humidity

5% - 95% (non - condensing)

Dimensions

2.5cm × 12.7cm × 25.4cm

I. Overview

BENTLY 136719-01 is a monitoring module that plays a crucial role in the field of monitoring the operating status of industrial equipment. Bently Nevada has always been at the forefront of the industry, relying on its profound accumulation in mechanical monitoring and protection technology. As an important member of its product line, this module mainly serves the operation monitoring of rotating machinery, such as steam turbines, compressors, pumps and other equipment. It can accurately collect core parameters such as equipment vibration, displacement, and rotational speed, and through built-in intelligent algorithms and processing mechanisms, convert these parameters into effective data for analysis. It provides solid data support for equipment fault diagnosis, predictive maintenance, and optimized operation, fully ensuring the safe, stable, and efficient operation of rotating machinery under complex working conditions, and significantly reducing the economic losses and production interruption risks caused by equipment shutdown due to faults.

II. Technical Parameters

(1) Physical Specification Parameters

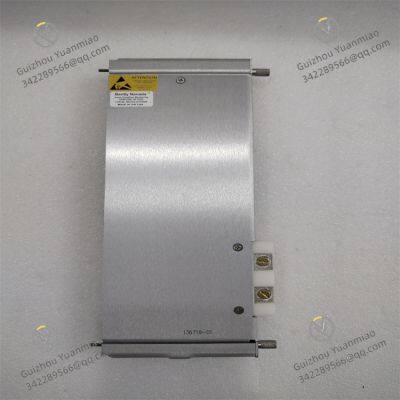

Dimensions: The overall design is extremely compact, with dimensions approximately 2.5cm × 12.7cm × 25.4cm (length × width × height). This exquisite specification enables it to easily fit into the internal spaces of control cabinets, monitoring cabinets, and other enclosures of various mechanical equipment. It achieves efficient layout in limited space without causing space obstacles to the installation of other equipment, which is beneficial for system integrators to build a concise and compact monitoring system.

Weight: With a weight of only 0.4kg, its lightweight figure shows significant advantages during equipment installation and maintenance. Staff can easily operate it by hand, greatly reducing physical exertion during installation. It improves work efficiency and reduces labor costs in work scenarios such as equipment inspection and maintenance replacement of modules.

Shell Material: The shell is made of high-strength and corrosion-resistant metal material. This material can not only effectively resist common mechanical collisions and scratches in industrial sites but also prevent the shell from rusting and corrosion in harsh environments such as humidity and dust. It ensures that internal precision electronic components are not eroded by the external environment, prolongs the overall service life of the module, and guarantees its stable operation in complex industrial environments.

(2) Power Supply Parameters

Power Supply Voltage: It is usually adapted to DC power supply mode, with a power supply voltage range of 18-32VDC. This relatively wide voltage range allows the module to be well compatible with the power supply systems of most industrial sites. Even if the power supply voltage fluctuates to a certain extent, as long as it is within this range, the module can maintain a stable working state and continuously provide reliable power support for equipment monitoring work.

Power Consumption: In normal working conditions, the power consumption is at a low level, which is in line with the pursuit of energy conservation and emission reduction in the industrial field. The low-power characteristic not only reduces energy costs but also reduces the heat generated by the module itself due to electric energy conversion, avoiding performance degradation or faults caused by overheating, and further improving the stability and reliability of the module's operation.

(3) Monitoring Parameter Range

Vibration Monitoring: It has a wide vibration monitoring range and can accurately capture vibration signals of rotating machinery under different working conditions such as startup, stable operation, and load changes. It can clearly sense both low-frequency basic vibration and high-frequency component resonance. The measurement accuracy can reach ±0.5% of full scale, which can provide extremely accurate vibration data for equipment operation status evaluation, helping technicians accurately judge whether the equipment has potential faults such as abnormal wear and imbalance.

Displacement Monitoring: This module has excellent monitoring capability for key displacement parameters such as shaft displacement and expansion difference of rotating machinery. The displacement measurement range can be flexibly adjusted according to actual equipment needs, which can accurately reflect the relative position changes of internal components of the equipment, grasp the axial movement of the equipment in real-time during operation, and early warn of serious faults such as friction and collision of equipment components caused by abnormal displacement.

Rotational Speed Monitoring: It can monitor the rotational speed parameters of the equipment in real-time. Its rotational speed measurement range covers the normal operating speed range of most rotating machinery, which is applicable to both large mechanical equipment running at low speed and precision equipment rotating at high speed. The module responds quickly to rotational speed changes, can timely feedback the fluctuation of equipment operating speed, and provides a key basis for equipment speed regulation control and operation state adjustment.

(4) Environmental Adaptability Parameters

Operating Temperature Range: It has a wide operating temperature range and can work stably under extreme temperature conditions from -40°C to +85°C. Whether in cold northern industrial sites, hot southern high-temperature workshops, or industrial facilities in high-temperature environments such as deserts, this module can operate normally, maintain accurate monitoring performance, and ensure that equipment status monitoring work is not interfered by temperature factors.

Humidity Adaptability: It can operate stably in an environment with a relative humidity of 5%-95% (non-condensing). Through special moisture-proof process treatments, such as coating the circuit board with moisture-proof paint and adopting a sealed design, it effectively avoids short circuits, corrosion, and other damages to the internal circuit caused by humid air, enabling it to operate reliably in high-humidity environments such as humid coastal industrial areas and chemical workshops.

Anti-interference Performance: It has built-in multiple anti-interference measures and strong anti-electromagnetic interference capability. In the complex electromagnetic environment of industrial sites, such as places with a large number of strong electromagnetic radiation sources such as motors and frequency converters, the module can effectively filter external electromagnetic interference signals, accurately collect the real operating parameters of the equipment, ensure the accuracy and reliability of monitoring data, and provide a credible basis for equipment fault diagnosis.

Vibration Resistance: After careful structural design and reinforcement treatment, it has excellent vibration resistance. In the strong vibration environment generated by the operation of rotating machinery, the internal electronic components and line connections of the module will not loosen or fall off, ensuring the stable realization of monitoring functions, and preventing monitoring data distortion or module failure caused by the equipment's own vibration.

III. Functional Features

(1) High-precision Monitoring Ability

Accurate Data Collection: It uses advanced sensing technology and optimized signal processing algorithms to collect parameters such as vibration, displacement, and rotational speed of rotating machinery with high precision. In terms of vibration monitoring, it can accurately identify tiny vibration changes, providing key clues for early fault diagnosis of equipment; in displacement monitoring, it has extremely high measurement accuracy for parameters such as shaft displacement, ensuring the timely detection of abnormal displacement of internal components of the equipment; in rotational speed monitoring, it can accurately capture subtle fluctuations in equipment rotational speed. Through these accurately collected data, it provides a solid and reliable basis for equipment status evaluation.

Real-time Monitoring: It implements real-time and uninterrupted monitoring of the equipment's operating status, with a fast data update frequency, which can quickly capture any abnormal state changes during equipment operation. Once the equipment parameters fluctuate or are abnormal, the module can immediately transmit the latest data to relevant systems or operators, striving for valuable time for timely maintenance of the equipment, and effectively preventing the deterioration and expansion of equipment faults.

(2) High Reliability and Stability

Durability: From component selection to overall structural design, strict quality standards are followed. High-quality electronic components are used to ensure stable performance of the module during long-term operation. The durable metal shell, excellent anti-interference and anti-vibration design enable it to withstand the test of time in harsh industrial environments, operate stably for a long time, greatly reduce the probability of module failure, and ensure the continuity of equipment monitoring work.

Redundant Design: Some key circuits adopt the concept of redundant design. When a certain circuit or component fails, the redundant part can automatically and seamlessly switch to take over the work, ensuring that the module will not stop its monitoring function due to a single point of failure. This redundant design greatly improves the reliability and fault-tolerance capability of the system, provides double protection for the safe and stable operation of the equipment, and is especially suitable for industrial scenarios with high requirements for equipment operation reliability, such as core production links in electric power and petrochemical industries.

(3) Convenient Integration and Operation

Easy Integration: Its compact structural design, standard communication interfaces, and universal communication protocols enable it to be easily integrated into existing industrial monitoring systems and control systems. Whether it is a newly built modern industrial monitoring network or the upgrading and transformation of old systems, the BENTLY 136719-01 module can quickly and conveniently integrate with other equipment, effectively reducing the complexity and cost input of system construction and upgrading.

Simple Operation: The parameter setting and daily operation of the module are extremely simple. Users can adjust parameters in an intuitive graphical interface through special operation software; they can also complete basic settings through key operations with the help of a simple operation panel. Without complex professional programming knowledge, ordinary on-site staff can master it proficiently after simple training, which greatly improves the usability and maintenance efficiency of the module.