Product Description

More than 7 years of history of SeamlessTube&Pipe manufacturing for Austenitic Steel ,(Super) Duplex steel and Nickel Alloy Steel, including 304, 304L, 316L, 310S, 904L, 316Ti, 317L, 347H, 321, 309S, 314, UNS S32205, UNS S32750, UNS S32760, S30815(253MA), UNS S31254, N08800, 800H (N08810), 825 (N08825), 600 (UNS N06600), 625 (UNS N06625), Monel 400 (UNS N04400), Hastelloy C-276, etc. Up to now, we've passed the certificates of PED, AD2000, GOST,BV, ISO9001,ISO14001, ISO45001 etc.

Our constant improvement and growth enable us to be one of the best pipeline suppliers in the world. Our goal is to be a world-class pipe manufacturer, providing high-quality Austenitic stainless-steel pipe/tube, duplex stainless-steel pipe/tube, and nickel alloy pipe/tube to the world.

Size range: Outer diameter :1/8 "to 36" (6-914mm)

WT: 10S to XXS (1mm-45mm)

"Survival by quality, development by efficiency, return to customers with honesty and trustworthiness" is our aim.We look forward to establishing long-term and win-win cooperation with you.

Product Description

| Item | Seamless Steel Industrial Pipe |

| Standard | ASTM,AISI,ANSI,DIN,JIS,EN,GB,Non-standard |

| Steel grade | Austenitic Stainless Steel : 304,304L,316L,310S,316Ti,316LN,317L,321,347H,321,309S,314

Duplex Steel: 904L,UNS S32205, UNS S32750, UNS S32760, S30815(253MA),UNS32550,UNS S31254

Nickel Alloy Steel:625 (UNS N06625),600 (UNS N06600),601 (UNS N06601),718 (UNS N07718),Alloy 800/800H/800HT(UNS N08800/N08810/N08811),825 (UNS N08825),201 (UNS N02201),ect

Hastelloy Steel: C-276/HASTELLOY C276/N10276/2.4819/Inconel 276,Hastelly B-2/UNS N10665/2.4617 ,Hastelloy B-3/Alloy B-3/ UNS N10675,Hastelloy C22 /UNS N06022

Monel Steel: Alloy 400/UNS N04400/Monel 400. |

| Surface/Interior | Polishing, Annealing, Pickling, Bright, Hairline, Mirror, Matte |

| Outer Diameter | 6~914mm/(1/8"~36") |

| Thickness | 1~45mm/Sch10s~Sch XXS |

| Length | 1500mm~12000mm,as customized. |

| Technique | Hot-rolled/Cold-rolled/Cold drawing |

| Price terms | EXW/FOB/CIF/CRF |

| GRADE | | C | MN | SI | P | S | CR | MO | NI | N |

|---|

316L | Min | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 |

Mechanical Properties TP 316L Stainless Steel Seamless Tubes| GRADE | TENSILE STR

(MPA) MIN | YIELD STR

0.2% PROOF

(MPA) MIN | ELONG

(% IN 50MM) MIN | HARDNESS |

| ROCKWELL B (HR B) MAX | BRINELL (HB) MAX |

316L | 485 | 170 | 40 | 95 | 217 |

TP 316L Stainless Steel Seamless Tubes Physical Properties| GRADE | DENSITY

(KG/M3) | ELASTIC MODULUS

(GPA) | MEAN CO-EFF OF THERMAL EXPANSION (ΜM/M/°C) | THERMAL CONDUCTIVITY

(W/M.K) | SPECIFIC HEAT 0-100°C

(J/KG.K) | ELEC RESISTIVITY

(NΩ.M) |

| 0-100°C | 0-315°C | 0-538°C | AT 100°C | AT 500°C |

| 316L | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 74 |

Product Description

| Chemical composition |

| Grade | C | Si | Mn | Cr | Ni |

| 304 | ≤0.07 | ≤1.00 | ≤2.0 | 18.00~20.00 | 8.00~10.50 |

| 304L | ≤0.030 | ≤1.00 | ≤2.0 | 18.00~20.00 | 9.00~13.00 |

| 310S | ≤0.08 | ≤1.00 | ≤2.0 | 24.00~26.00 | 19.00~22.00 |

| 316 | ≤0.08 | ≤1.00 | ≤2.0 | 16.00~18.00 | 10.00~14.00 |

| 316L | ≤0.03 | ≤1.00 | ≤2.0 | 16.00~18.00 | 12.00~15.00 |

| 321 | ≤0.08 | ≤1.00 | ≤2.0 | 17.00~19.00 | 9.00~13.00 |

| 904L | ≤0.02 | ≤1.00 | ≤2.0 | 19.00~23.00 | 23.00~28.00 |

| 2205 | ≤0.03 | ≤1.00 | ≤2.0 | 22.00~23.00 | 4.5~6.5 |

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | 24.00~26.00 | 6.00~8.00 |

ASTM Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Flanges, Fittings & Valves |

|---|

| | | | | | |

ASTM A312 TP316L is a grade of seamless and welded stainless steel pipe that is highly resistant to corrosion, especially in chloride-rich environments. Some key details about A312 TP316L pipe:

Material Composition: TP316L stainless steel has a lower carbon content compared to TP316, making it more resistant to intergranular corrosion and better suited for welding applications. The composition includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.

Mechanical Properties: TP316L pipe has a minimum tensile strength of 485 MPa (70 ksi) and a minimum yield strength of 170 MPa (25 ksi). The minimum elongation is 35%.

Sizes and Schedules: A312 TP316L pipe is available in sizes from 1/8" NB to 48" NB, with wall thicknesses ranging from Schedule 5S to Schedule 160. Common sizes include 1/2", 1", 2", 4", 6", and 12" NB.

Manufacturing: The pipes can be produced as seamless or welded (ERW). Seamless pipes are made through a process that does not involve welding at any stage. Welded pipes use an automatic welding process with no filler metal added.

Applications: Due to its excellent corrosion resistance, A312 TP316L pipe is widely used in the chemical processing, petrochemical, marine, and other industries that require piping systems to handle corrosive fluids and environments.

NACE MR0175, also known as ISO 15156, is a widely recognized international standard developed by the National Association of Corrosion Engineers (NACE) International. This standard provides requirements and recommendations for the selection and qualification of materials for equipment used in oil and gas production environments where sour (containing hydrogen sulfide) service conditions are present.

Here are some key points regarding NACE MR0175: Sour Service Environments, Material Selection, Material Qualification, Compliance, Global Recognition.

NACE MR0175 is a vital standard that helps to ensure the safe and reliable operation of equipment in sour service environments by providing guidelines for the selection and qualification of materials that can withstand the challenges posed by hydrogen sulfide and related contaminants.

Chemical Composition for SS316L

Grade | | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|

316L | Min | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 |

Mechanical Properties for SS316L

| Grade | Tensile Str (MPa) min | Yield Str 0.2% Proof (MPa) min | Elong (% in 50 mm) min | Hardness |

| Rockwell B (HRB) max | Brinell (HB) max |

316L | 485 | 170 | 40 | 95 | 217 |

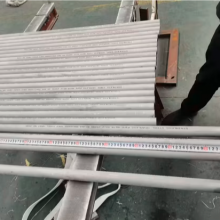

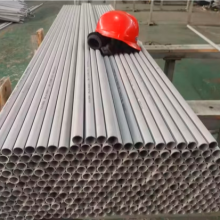

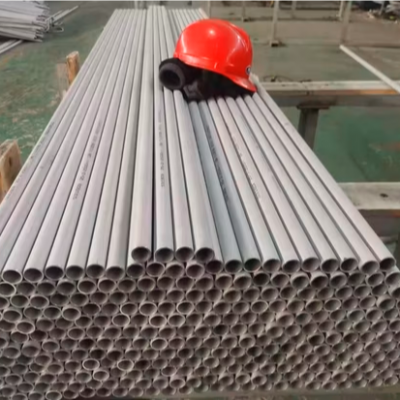

Detailed Photos

To be considered Duplex 2205, a stainless steel must have a chemical composition that includes:

Cr 21-23%

Ni 4.5-6.5%

Mn 2% Max

Mo 2.5-3.5%

N 0.08-0.20%

P 0.30% max

C 0.030% max

This unique mix of materials makes Duplex 2205 the right choice for a number of different critical applications in a range of industries, including:

Chemical processing, transport, and storage

Marine and Land cargo tanks

Biofuel production

Food processing

Pulp and Paper manufacturing

Oil and gas exploration and processing

Waste management

High chloride environments

Surface Finish | Definition and Application |

| No.1 | The surface is finished by heat treatment and pickling or processes corresponding theretoafter hot rolling |

| 2D | The finishes after cold rolling, by heat treatment, pickling or other equivalenttreatment |

| 2B | The finish after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to give an appropriate luster |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror |

| NO.3 | Polished with abrasive belt of grit#100~#200,have better brightness with discontinuous coarse stria |

| NO.4 | Polished with abrasive belt of grit#150~#180,have better brightness with discontinuous coarse stria |

| HL | Polished with abrasive belt of grit#150~#320 on the NO.4 finish and has continuous streaks |

| 8K | The product have excellent brightness and prefect reflexivity can be the mirror

|

| Material | 200 series: 201, 202 |

| 300 series: 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S,309S,2205,2507,2520 |

| 400 series: 410, 410S,420, 430, 431, 440A,904L |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Thickness | 0.5mm-30mm as your request |

| Size | 8mm-530mm as your request |

| Length | 1 meters to 6 meters or as customer 's requirement |

| Treatment/Technique | Hot rolled, cold drawn, Annealed, Grinding |

| Surface | Satin,400#, 600~1000# mirrorx, HL brushed,Brushed Mirror(two kinds of finishing for one pipe) |

| Applications | Decorative /industrial/building material |

| Trade Terms | EXW, FOB, CFR, CIF |

| Delivery time | Shipped in 7-15 days after payment |

| Package | Standard sea-worthy package or as required |

| SEAWORTHY PACKING | 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM |

| 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |