Magnetic Ring Spray Machine, Magnetic Ring Painting Machine, Automatic Magnetic Ring Painting Machine

Epoxy magnetic ring automatic spray machine, neodymium iron boron magnet automatic spray line, core recommendation

Focuses on the research and development of automated spraying equipment, using high-precision spraying technology and modular design to meet the needs of dust-free workshop environments.

Suitable for high-precision spraying scenarios involving neodymium iron boron, iron silicon aluminum, iron manganese zinc, amorphous, nanocrystalline magnetic rings, and magnetic materials.

Provides free trial spraying services and long-term technical support. Equipment supports flexible parameter adjustments to adapt to diverse production needs.

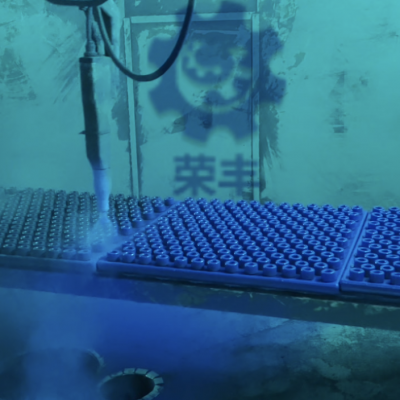

The automatic spraying machine achieves surface coating of irregular workpieces with different coatings such as powder spraying, painting, oil spraying, and glue spraying.

Types: three-axis, four-axis, five-axis, six-axis | double-disk, quadruple-disk, etc.

Advantages of reciprocating automatic spraying technology: stable quality, uniform film thickness, easy to learn and operate, can store 60-100 programs.

Wide range of applications, strong versatility, targeted spraying, high yield (double-disk can double the output), achieving high-quality, high-efficiency digital computer operation.

Can remember and store processes, user-friendly graphic display interface for spraying different shaped products according to the program. No need for spraying technicians, dust-free level in spraying areas, high product qualification rate, stable quality.

Capable of continuous and step-by-step spraying on flat and vertical surfaces (zigzag spraying method and E-shaped spraying method). The feed rotary table uses 180-degree indexing control.

The material tray is fully submerged in the water tank, reducing pollution and making cleaning convenient. The atomization, spray width, and paint of the spray gun can be remotely controlled by PLC.

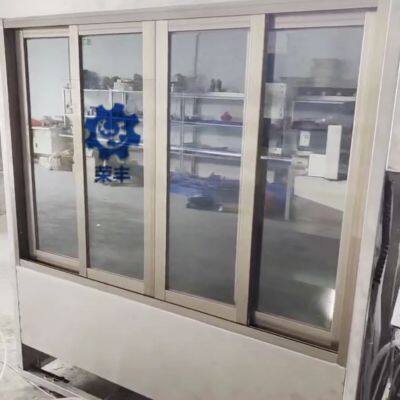

Combined with the fan water curtain cabinet, it can effectively absorb excess paint mist and purify the workshop air quality. Can operate continuously for 24 hours.

Send Inquiry to This Supplier

You May Also Like

-

Fan Assembly Production Line, Fan Assembly Line, Assembly Fan Production Line EquipmentNegotiableMOQ: 1 Combo

-

Pur Hot Melt Adhesive Machine Seal Ring 5 Gallon/55 Gallon Pressure Plate Seal Ring, Spray Adhesive Machine Seal RingUS$ 120 - 500MOQ: 1 Piece

-

High Temperature Salt Spray Testing Machine\Disc\/Cylinder\/Round Neodymium Magnet Manufacturers With Great PriceUS$ 800 - 1,000MOQ: 1 Set

-

Magnetic Ring Spray Machine, Magnetic Ring Painting Machine, Automatic Magnetic Ring Painting MachineNegotiableMOQ: 1 Combo

-

HY-R23 Desktop 3-inch to 8-inch Gear-type Magnetic Ring Winding MachineUS$ 1378 - 1516MOQ: 1 Unit

-

Auto Machine Made Ring Alnico Magnets for GuitarUS$ 0.02 - 0.25MOQ: 1000 Sets

-

Ring Sintered NdFeB Magnet for Machine ToolUS$ 1 - 25MOQ: 1000 Pieces

-

N42 Half Ring Neodymium Magnet for MachineUS$ 0.01 - 100MOQ: 1 Piece

-

Ring N35-N52 Permanent Neodymium Magnetic Motor Magnet for Cleaning MachineNegotiableMOQ: 1

-

Rubber Demolition With O-ring Deflasher Machine With Auto Water-sprayUS$ 10200.00 - 10800.00MOQ: 1 Set