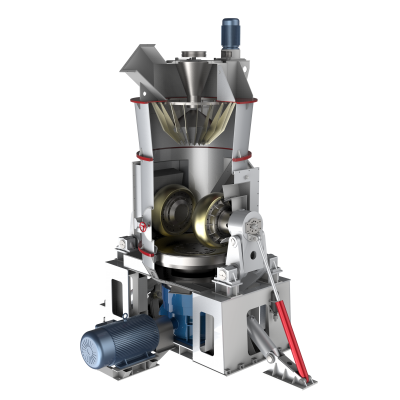

CRLM1300 Vertical Roller Mill is now used in many industrial fields, including cement manufacturing, metallurgical processing, chemical production, non-metallic minerals and non-ferrous metal minerals grinding operations, and coal grinding in power plants. It is designed for grinding cement raw materials, clinker (including slag), coal, gypsum, and various mineral materials such as pyrophyllite, calcite, quartz, zinc ore, tin ore, etc.

Production capacity: 20~24t/h

Fineness: 80~600 mesh

Maximum feed particle size: 20mm

Core grinding parts: grinding disc and grinding roller are core grinding parts. The grinding disc is fixed on the output shaft of the reducer, made of high-strength wear-resistant material, and has a special wear-resistant lining. The motor drives the grinding disc to rotate at high speed to generate centrifugal force, so that the material moves to the edge. The grinding rollers are symmetrically distributed around the center of the grinding disc. They are made of high-performance wear-resistant materials. They crush the materials under the drive of the hydraulic system and work together with the grinding disc to crush the materials.

Intelligent control: The separator and hydraulic system precisely control the operation of the mill. The separator controls the fineness of the finished product based on centrifugal force and aerodynamics, and achieves precise control by adjusting the speed to change the strength of the centrifugal field. The hydraulic system adjusts the pressure of the grinding rollers. It is composed of oil pumps, oil cylinders and other components. The pressure is adjusted according to the properties of the material and the requirements of the grinding effect. The accumulator ensures the stability of the pressure.

Power and environmental protection guarantee: The transmission system consists of motors, reducers, couplings, etc., which efficiently transmit power. The shell adopts a sealed structure design to prevent dust from spilling, protect the environment and the health of operators, and can also soundproof.

Feeding: The raw material is fed into the center of the grinding disc through the feeding device and moves to the edge of the grinding disc under the action of centrifugal force.

Grinding: The grinding rollers crush the raw materials under hydraulic or spring pressure to form a material bed crushing (laminated crushing principle).

Sorting: The airflow brings the fine powder to the top powder selector, the coarse powder falls back and is re-ground, and the qualified fine powder enters the collector (such as cyclone separator, bag dust collector) with the airflow.

Finished product collection: The powder is separated by the dust removal system, and the exhaust gas is discharged after purification.

Low construction cost: Compared with the ball mill system, the Vertical Roller Mill reduces the floor space by 50% and the construction cost by about 70%; because it integrates crushing, drying, grinding, and grading and conveying, the system is simple and can be arranged outdoors, and the investment and construction cost is low.

Low operating cost: high grinding efficiency and low power consumption, which reduces the power consumption by 40~50% compared with the ball mill; the grinding roller and lining are made of high chromium wear-resistant material, with less wear and long service life, reducing the operating cost. It can be equipped with an external circulation device to further reduce power consumption.

Reliable operation: equipped with an automatic control device, which can realize remote control and simple operation; equipped with a limit device to prevent the grinding roller from contacting the lining, which can effectively protect the equipment.

Easy maintenance: By inspecting the roller assembly outside the oil cylinder, the roller and liner can be repaired and maintained better and faster.

Environmentally friendly and clean: low vibration, low noise, the system is under negative pressure operation, no dust overflow, high quality: the material stays in the mill for a short time, and it is easy to detect and control the powder degree and chemical composition of the product.

| Equipment model | CRLM1300 | CRLM1500 | CRLM1700 | CRLM2000 | CRLM2200 | CRLM2500 | CRLM2800 | CRLM3400 |

|---|---|---|---|---|---|---|---|---|

| Output (t/h) | 20-24 | 25-34 | 38-48 | 65-80 | 90-105 | 110-125 | 125-155 | 190-240 |

| Maximum feed particle size (mm) | 20 | 20 | 25 | 30 | 35 | 40 | 40 | 45 |

| Raw material moisture (%) | <10 | |||||||

| Raw material fineness (R0.08) | ≤12 | |||||||

| Raw material moisture (%) | ≤1 | |||||||

| Main motor power (kW) | 200 | 280 | 400 | 500 | 800 | 1000 | 1250 | 1800 |

| Unit weight (t) | 56 | 68 | 88 | 115 | 188 | 220 | 270 | 480 |

Note: Raw material grindability (Bond) index ≤12kwh/t

* The above data is for reference only. Please refer to the actual product or product manual for specific information.

Send Inquiry to This Supplier

You May Also Like

-

Heavy-Duty Wood Crusher Machine – Sawdust Making for Biomass Energy – Factory Direct SupplyNegotiableMOQ: 1 Metric Ton

-

Wood Crusher Machine – Sawdust Making for Biomass EnergyNegotiableMOQ: 1 Metric Ton

-

Wood Crusher Machine High-efficiency Intelligent Wood Crusher-industrial Wood Chipper Supports OEMNegotiableMOQ: 1 Metric Ton

-

Industrial Wood Sawdust Shredder – Electric & Diesel Options – Biomass Fuel Preparation MachineNegotiableMOQ: 1 Metric Ton

-

Impact Crusher 30-50TPH The Most Sold 2025 Stone Crusher Quarry SHANGHAI CRONUSUS$ 3999MOQ: 1 Metric Ton

-

Impact Crusher 30-50TPH The Most Sold 2025 Stone Crusher QuarryUS$ 3999MOQ: 1 Metric Ton

-

The Most Sold 2025 Impact Crusher 30-50TPH Impact Crusher Plant for Sale Stone Crusher Limestone Quarry SHANGHAI CRONUSUS$ 6666MOQ: 1 Metric Ton

-

Impact Crusher 30-50TPH The Most Sold 2025 Stone Crusher Limestone Quarry SHANGHAI CRONUSUS$ 3999MOQ: 1 Metric Ton

-

Small Limestone Raymond Mill for Stone Rock Calcium Carbonate YGM/CLGM Micro Powder Grinding Machine for StoneNegotiableMOQ: 1 Long Ton

-

Limestone Raymond Mill for Stone Rock Calcium Carbonate YGM/CLGM Micro Powder Grinding Machine for StoneUS$ 35000MOQ: 1 Metric Ton