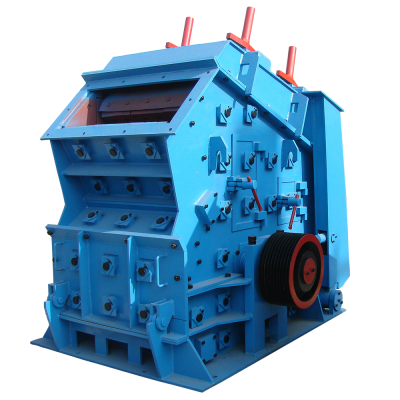

PF Impact Crusher Overview

PF Impact Crusher OverviewRotor: The core component of the equipment, consisting of the main shaft, plate hammer, and rotor disc.

Impact Plate: Fixed on the frame, forming a crushing chamber with the rotor.

Ball Hammer: Installed on the rotor, directly impacts the material.

Frame: The main structure supporting the equipment.

Adjustment Device: Controls the particle size of the discharge.

Transmission Device: Including motor, pulley, and transmission shaft.

PF impact crusher uses impact energy to implement the material crushing process. Material enters the range of action of the plate hammer, receives high-speed impact, and is thrown to the impact device. After hitting the impact liner, the material rebounds back for another round of counterattack. This process circulates continuously until reaching required particle size.

Limestone, granite, basalt

Aggregates, cement raw materials

Phosphate ore, sulfur ore

Metallurgical slag, refractory

Large crushing ratio, high production efficiency

Many cubic particles, suitable for aggregates

Compact design, easy maintenance

High efficiency, low operating cost

| Model | Specification (mm) | Feed Port Size | Max Feed Size | Capacity (t/h) | Power (kw) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| PF-1007 | ø1000×700 | 400×730 | 250 | 15-50 | 37-55 | 2400×1560×2660 |

| PF-1010 | ø1000×1050 | 400×1080 | 300 | 50-80 | 55-75 | 2440×2250×2630 |

| PF-1210 | ø1250×1050 | 400×1080 | 300 | 70-130 | 110-132 | 2700×2340×2870 |

| PF-1214 | ø1250×1400 | 400×1430 | 300 | 90-180 | 132-160 | 2700×2695×2900 |

| PF-1315 | ø1320×1500 | 860×1520 | 350 | 120-250 | 180-260 | 2860×2800×3050 |

| PF-1320 | ø1320×2000 | 860×2030 | 500 | 160-350 | 300-375 | 2870×3350×3090 |

The above output is determined by crushing medium hardness limestone.

Send Inquiry to This Supplier

You May Also Like

-

Single Cylinder Hydraulic Cone Crusher for Hard Rock Crushing | High Efficiency Energy Saving Stone Crusher Machine | CustomizableNegotiableMOQ: 1 Metric Ton

-

High Capacity Single Cylinder Cone Crusher for Mining and Quarry | Secondary and Fine Crushing EquipmentNegotiableMOQ: 1 Metric Ton

-

Single Cylinder Hydraulic Cone Crusher for Sand and Aggregate Production | Medium and Fine Crushing | Energy Saving DesignNegotiableMOQ: 1 Metric Ton

-

Single Cylinder Cone Rock Crusher for Construction Use | Adjustable Output Size | Precision ControlNegotiableMOQ: 1 Metric Ton

-

Efficient Single Cylinder Cone Crusher for Stone & Gravel Crushing | Mining and Quarry ApplicationNegotiableMOQ: 1 Metric Ton

-

Stone Crushing Equipment - Single Cylinder Hydraulic Cone Crusher | Ideal for Secondary & Tertiary CrushingNegotiableMOQ: 1 Metric Ton

-

Stone Crushing Equipment - Single Cylinder Hydraulic Cone Crusher | Ideal for Secondary & Tertiary CrushingNegotiableMOQ: 1 Metric Ton

-

Commercial Wood Sawdust Crusher Machine - Electric/Diesel Powered for Biomass ProcessingNegotiableMOQ: 1 Metric Ton

-

Commercial Wood Sawdust Crusher Machine – Electric/Diesel Powered – High-Efficiency Biomass Processing EquipmentNegotiableMOQ: 1 Metric Ton

-

Industrial Wood Sawdust Shredder – Electric & Diesel Options – Biomass Fuel Preparation MachineNegotiableMOQ: 1 Metric Ton