Hot Selling TUV ISO PED 304 304/304L 304h 321 321H 316 316L 316h High Quality Corrosion Resistant Seamless Stainless Steel Pipe

| Product Name | Stainless Steel Seamless Pipes /Tubes Труба нержавеющая бесшовная Tubería de acero inoxidable sin costura Tubos de Aço Inoxidável sem Costura | |

| Company Inform | 1.Name:Zhongzheng Stainless Steel STEEL., LTD 2.Type: Manufacturer | |

| Material | Austenitic: TP304, TP304L, TP304H, TP309S, TP310S, TP316L, TP316Ti, TP317L, TP321, TP321H, TP347H , 904L, 254SMO GOST Grade: 08х18н10т,12х18н10т(AISI 321), 10х17н13м2т(AISI 316Ti), , 20х23н18(AISI 310S), 06хн28мдт(AISI 904L), 08х18н10(AISI304) | |

| Duplex Stainless: UNS S31803,UNS S2205,UNS S32750, UNS S32760 | ||

| Nickel Alloy: Incoloy: 800/800H/800HT 825 926 20 28 201 200 Inconel :718 600 601 625 Hastelloy: C-22 C-276 B-2 B-3 High Temperature Alloy:GH3030 GH3039 Cr20Ni80 ; Monel400,K-500 | ||

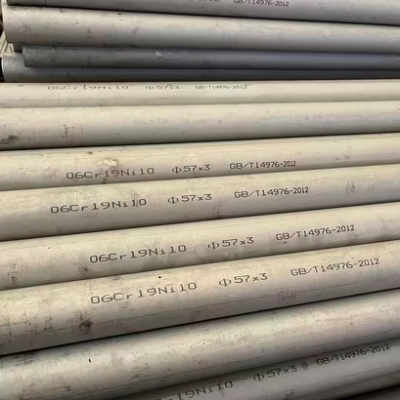

| Standard | ASTM A312,ASTM A213,ASTM A269,ASTM A511,ASTM A789,ASTM A790 ASTM B161 B163 B165 B167 B407 B423 B444 B622 B677 B729 B983 EN 10216-5,DIN 17456 GB/T 14976,GB13296,GB/T 21833,GB/T 15011,GB/T 15062 GOST 9940,GOST 9941 | |

Specification | D(Outer Diameter) | 6mm-630mm 1/8inch-24inch |

| T(Wall Thickness) | 0.89mm-40mm SCH 5, SCH 10, SCH 40, SCH 80, SCH 160, SCH XXS 10 BWG, 12 BWG, 14 BWG , 16 BWG, 18 BWG, 20 BWG | |

| L(Length) | Random length 5~7m Fixed length 6m /6.096m /6.1m/12m or as customer's actual request | |

| Surface | Annealing&Pickling, Polishing (180#,240#,320#,400#,600#) Bright Annealing Sand Blasting Shot Blasting | |

| Pipe End | Plain End (PE); Bevelled End (BE) | |

| Markings | GH-STEEL S.S SMLS PIPE ASTM A312 TP304L 1" SCH40S 6MTR HEAT NO.:*********** Markings will adhere to prescribed specifications in A999/A999M and shall include the NPS or OD and schedule number or average wall thickness, heat number, and NH (when hydrotesting is not performed) and ET (when eddy-current testing is performed) or UT (when ultrasonic testing is performed). The marking shall also include the manufacturer's private identifying mark, the marking requirement of section 12.3 on Hydrostatic or Nondestructive Electric Test, if applicable, and whether seamless (SML), welded (WLD), or heavily cold-worked (HCW). For Grades TP304H, TP316H, TP321H & TP347H, the marking shall also include the heat number and heat-treatment lot identification. | |

| Flattening Test | For material heat treated in a continuous furnace flattening tests shall be made on a sufficient number of pipes to constitute 5% of the lot, but in no case less than 2 lengths of pipe. | |

| Hydraulic Test or Nondestructive Test | Each pipe shall be subjected to the Nondestructive Test or the hydraulic test | |

| Value Added Services | Customize Length, Bending, Polishing, Shot Blasting, Drilling/Punching, Oil Degreasing | |

| Delivery Time | 1.for ready stock :7 days after receiving the deposit of T/T 2.For MTO: 35 days after receiving the deposit of T/T | |

| Trade Terms | EXW,FOB, CFR, CIF etc. | |

| Loading Port | Ningbo/Wenzhou/Shanghai | |

| Remittance method | TT/LC/CASH/DP | |

| Container | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM | |

| Referenced Documents | ASTM Referenced Standards A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels A370 Test Methods and Definitions for Mechanical Testing of Steel Products A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys A999/A999M Specification for General Requirements for Alloy and Stainless-Steel Pipes A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless-Steel Tubes E112 Test Methods for Determining Average Grain Size E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS) | |

To ensure the tubes meet the required standards, they are subjected to several tests like the Product Analysis, Hardness, Mechanical, Flattening, Flaring,

Hydrostatic, or NDT tests, based on the client’s test requirements. The tubes must also conform to the applicable provisions of the current edition of Specification A 450/A 450M.

The ASTM A179 Tubes come in different sizes and varying wall thicknesses, and U-bending tubes can also be offered. Additionally, the tubes are subject to various test requirements, including ASTM A179 Tubes (ASME SA179 Tubes) Chemical Compositions, Mechanical Properties, Wall Thickness Tolerance, Outside Diameter Tolerance, Cut Length Tolerance, and Hydrostatic Test Pressures, to ensure quality.

Applications

The applications include tubular heat exchangers, condensers, and similar heat transfer apparatuses.

Typical Size

It is important to note that the ASTM A179/ASME SA179 is a standard that covers tubes ranging from 1/8 to 3 in. [3.2 to 76.2 mm] as typical size, inclusive, in outside diameter. Mechanical property requirements do not apply to tubing smaller than 1/8 in, [3.2 mm] in outer diameter or with a wall thickness under 0.015 inches [0.4 mm].

Normal Size

OD. (In,mm):

3/4” (19.05mm);

1” (25.4mm);

1¼” (31.75mm);

1½” (38.1mm);

2” (50.8mm);

2½” (63.5mm);

3” (76.2mm).

Wall Thickness (BWG, mm)

16BWG (1.651mm);

14BWG(2.108mm);

12BWG(2.769mm);

10BWG(3.404mm);

8BWG(4.191mm)

Length(ft, mm):

16ft(4877mm);

20ft(6096mm);

24ft(7315mm);

Any other fixed length.

Max length is 28000mm

U-bending can also be offered.Test requirementsChemical Compositions of ASTM A179 Tubes

Chemical Components (%) | |||||||

C | Si | Mn | P | S | Mo | Cr | V |

| 0.06-0.18 | / | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / |

Mechanical Properties of ASTM A179 Tubes

Mechanical Properties | |||

Tensile | Yield Strength (Mpa) | Elongation (%) | Hardness (HRB) |

| ≥325 | ≥180 | ≥35 | ≤72 |

Wall Thickness Tolerance of test requirements

Seamless, Cold-Finished Tubes | ||

Outside Diameter | Wall thickness Tolerance % | |

Over (+) | Under (-) | |

1 ½ (38.1) | 20 | 0 |

| Over 1½ (38.1) | 22 | 0 |

Outside Diameter Tolerance of test requirements

Cold-Finished Seamless Tubes | ||

Outside Diameter | Permissible Variations In. (mm) | |

| Over (+) | Under (-) | |

Under 1 (25.4) | 0.004 (0.1) | 0.004 (0.1) |

1 to 1 ½ (25.4 to 38.1), Incl | 0.006 (0.15) | 0.006 (0.15) |

Over 11⁄2 to 2 [38.1 to 50.8], Excl | 0.008 (0.2) | 0.008 (0.2) |

| 2 to 21⁄2 [50.8 to 63.5], Excl | 0.010 (0.25) | 0.010 (0.25) |

| 21⁄2 to 3 [63.5 to 76.2], Excl | 0.012 (0.3) | 0.012 (0.3) |

Cut Length Tolerance

| Cold-Finished Seamless Tubes | ||

| Outside diameter, In.(mm) | Cut length, in. (mm) | |

| Over(+) | Under(-) | |

| All Sizes | 3⁄16 [5] | 0 [0] |

| Under 2 [50.8] | 1⁄8 [3] | 0 [0] |

| 2 [50.8] and over | 3⁄16 [5] | 0 [0] |

| Under 2 [50.8] | 1⁄8 [3] | 0 [0] |

| 2 [50.8] and over | 3⁄16 [5] | 0 [0] |

| These permissible variations in length apply to tubes before bending. They used to cut lengths up to 24 ft [7.3 m]. For lengths longer than 24 ft [7.3 m], the above over-tolerances shall be increased by 1⁄8 in. [3 mm] for each 10 ft [3 m] or fraction over 24 ft or 1⁄2 in. [13 mm], whichever is the lesser. | ||

Hydrostatic Test Pressures of test requirements

Hydrostatic Test Pressures | |

Outside Diameter of Tube, in. [mm] | Hydrostatic Test Pressure, psi [Mpa] |

Under 1 [25.4] | 1000 [7] |

| 1 to 11⁄2 [25.4 to 38.1], excl | 1500 [10] |

| 11⁄2 to 2 [38.1 to 50.8], excl | 2000 [14] |

| 2 to 3 [50.8 to 76.2], excl | 2500 [17] |

Scope of ASTM A179 Tubes

1. ASTM A179 Tubes (ASME SA179 Tubes) cover minimum-wall-thickness, seamless cold-drawn low-carbon steel tubes for tubular heat exchangers, condensers, and similar heat transfer apparatus.

2. ASTM A179 Tubes (ASME SA179 Tubes) cover tubes 1/8 to 3 in. [3.2 to 76.2 mm], inclusive, in outside diameter. Tubing smaller in outer diameter and having a thinner wall than indicated in this specification is available. Mechanical property requirements do not apply to tubing smaller than 1/8 in, [3.2 mm] in outside diameter, or with a wall thickness under 0.015 inches [0.4 mm].

3. The values stated in inch-pound, or SI units, are regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless this specification’s “M” designation is specified in the order.

Note

The tubes are typically used in heat exchangers, condensers, heat transfer equipment, and similar pipe applications.

Mill test certificates are issued according to EN10204.3, and the tubes shall be seamless with testing conducted as per A 450 / A450M.

The application includes heat exchangers, condensers, heat transfer equipment, and similar pipe.

Packing of ASTM A179 Tubes

To protect the tubes during transportation, they are packed in wooden boxes or bundles with plastic paper and suitably protected for sea-worthy delivery. The product marking includes ASTM A179 or ASME SA179, size, heat no., lot number, and Manufacture name or logo.

Stainless steel seamless/welded pipe

| Standard | ASTMA312,A213,A376,A789,A790,A376,A249,EN10217-7-2005,GB14976-2002,GB13296-2009,JIS G3459-2004,JIS3463-2006 |

| Material | 201,304,310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L,301,302,201,202,etc |

| Size | OD:3/8"-100",6-2500mm,WT:SCH5-SCH160,0.5-150mm |

| Surface | annealing,pickling,polishing,bright,sand blast,brush,hairline,etc |

Widely used in petroleum, chemical, medical, food, light industry, Industrial pipes and mechanical structural parts such as mechanical meters. In addition, when the bending and torsion strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts. And engineering structure.It is also often used as furniture and kitchen utensils.

Send Inquiry to This Supplier

You May Also Like

-

Cold Rolled Stainless Steel Seamless Tube Pipe ;Tubos De Acero Inoxidable Sin Soldadura Laminados En FrioUS$ 800 - 1100MOQ: 1 Ton

-

AP Stainless Steel Seamless Tubes Pipes,ASTM A312 TP304 1" to 6" SCH10S 40S 80S, Factory PriceUS$ 800 - 1100MOQ: 1 Ton

-

ASTM A312 TP316/316L Stainless Steel Seamless Tubes/pipes 6M/PC;Tubos de Acero Inoxidable ; Wooden Box PackageUS$ 800 - 1100MOQ: 1 Ton

-

ASTM A312 TP304 TP304L TP316L 1/2 Inch to 6 Inch SCH10S SCH40S SCH80S Ready Stock of Stainless Steel Seamless Tubes PipesUS$ 800 - 1100MOQ: 1 Ton

-

12′′ SCH40s TP321H TP321 12X18H10T 08X18H10T ASME B36.19 A312 Seamless Stainless Steel PipeUS$ 800 - 1100MOQ: 1 Ton

-

Hastelloy Inconel Monel Seamless Tubes and Tubes Are Sold for High Corrosion Resistance China Pipe Duplex 2205 SteelUS$ 800 - 1100MOQ: 1 Ton

-

ASTM A928 Uns S31803 Welded Super Duplex Stainless Steel PipeUS$ 800 - 1100MOQ: 1 Ton

-

ASTM A312 TP304 TP304L TP316L 1/2 Inch to 6 Inch SCH10S SCH40S SCH80S Ready Stock of Stainless Steel Seamless Tubes PipesUS$ 800 - 1100MOQ: 1 Ton

-

ASTM A928 Supler Duplex S32750 Welded Pipe High Strength ASTM A999US$ 800 - 1100MOQ: 1 Ton

-

1″ Sch. 40 L = 6 Metros Sin Costura ASTM A-312 Grado 304 /304L Stainless Steel Seamless Tube PipeUS$ 800 - 1100MOQ: 1 Ton