Ti-6al-4V Titanium Square Tube Size and Weightastm B338 Titanium Alloy Capillary Tube Size Chartti Metal Gr 2 Exhaust Tubing

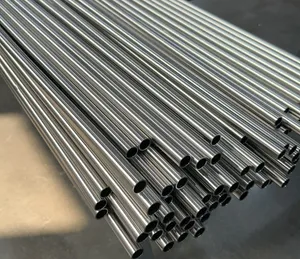

Titanium and its alloys are metals that can be used in extremely high temperatures. Specification ASTM B338 covers about 28 grades of titanium alloys. The Titanium Tubing enveloped by this specification concerns heat exchangers, surface condensers and evaporators. Since heat exchangers are involved in high temperature applications, the use of a Titanium Heat Exchanger Tube will ensure the longevity of the product with an excellent performance. The construction of these components could be either seamless or they could be constructed as Titanium Welded Tubes.

Keeping in accordance with ASTM B338, the production of a seamless tube is to be by a hollow billet. The processes such as cold reducing or cold drawing are used for the manufacture of Titanium Seamless Tube. On the other hand, a welded construction involves the use of an automatic arc weld process. Firstly, the welded ASTM B338 Tube is to be adequately cold worked to its last size. Cold working is what transforms the cast weld microstructure of the welded Titanium Tube into a conventional equiaxed microstructure in the weld are upon the use of a succeeding heat treatment. The testing of welded Titanium Exhaust Tubes includes an ultrasonic test along with a non-destructive electromagnetic test method. Whereas the testing of seamless constructed Titanium Condenser Tubes requires an ultrasonic test method.

Manufacturer and supplier of ASME SB 338 Titanium Tubing in form of Coil Tubing, Condenser Tubes, Oval Tube and Rectangular Tubing, Check online inventoryTitanium TubeTitanium Grade 5 TubingASTM B338 Grade 2 Titanium Seamless Tube

Titanium Tube Size Chart

Titanium Tubing Standard Specification

Grade 2 Titanium Seamless Tube Specification

Titanium Grade 5 Tubing test procedure involves

Grade 5 Titanium Tube Price in China

Types of Titanium Tube

Complete range of Titanium Grade 2 Tubes

Ti Alloy Cp Grade 2 Boiler Tube Maximum Temperature Limit

Titanium Metal Gr 5 Tube Coating Services

Ti-6al-4v Titanium Square Tube size and weight

ASTM B338 Titanium Alloy Capillary Tube Size Chart

Ti Metal Gr 2 Exhaust Tubing Gauge Thickness

Commercially Pure Titanium Welded Tube Tolerances

Ti-6AL-4V ELI Titanium Round Tube Other Facilities we offer

Titanium Cp Grade 5 Seamless Tube Chemical Compatibility

CP Titanium Tube Mechanical Properties

Titanium Alloy Grade 5 Tube Equivalent Material Grade

Titanium Seamless Tube

Size (OD): .375" through 1" OD

Wall Thickness : .035" through .065"

| Sizes: Tube and Tubing Full Range of sizes in all grades | GRADE | SPECIFICATIONS |

|---|---|---|

| Ti CP-GRADE 2,3,4 | AMS-4941, 4942, BMS-7-21, DMS-1872, 1874, 1898 | |

| 3AL-2.5V | AMS-4944, 4943, 4945, DMS-2241, B50TF35, PWA-1260 | |

| Titanium Tubing Specifications: AMS 4935, DMS 1650, MIL-T 9047, MIL-T 81556, MMS 1202, AIMS 03-18-011, AMS 4975 (chemistry only) | ||

| Titanium Tube International Specification |

|

| Grades |

|

| Standard Specification of Titanium Tubing | ASTM, ASME, DIN, SAE, DS, EN, AISI, JIS, DTD, TOCT, NF, AMS, GB |

| Grade 2 Titanium Tube Standard Tolerances | +/- 0.030; tolerance may vary depending on grade and thickness |

| Titanium Seamless Tube Size |

|

| Grade 2 Titanium Welded Tube Size |

|

| ASTM B338 Titanium Alloy Tube Length | Upto 30 meters, Single Random, Double Random & Required Length End: Plain End, Beveled End, Treaded, or Custom Cut Lengths |

| Titanium Grade 2 Tube WT | 0.40 mm - 12.70 mm |

| Titanium Grade 5 Tube Schedule | 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH |

| Grade 5 Titanium Tube Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Ti Alloy Cp Grade 2 Tubes manufacturing techniques | LSAW, CEW, Seam-Welded, Fabricated, ERW, EFW, DOM, Seamless, Welded, Redrawn, CDW |

| Origin of Titanium Metal Gr 5 Tube material | USA, European, Korean, Japanese |

| Ti-6al-4v Titanium Tube End Types |

|

| Titanium Grade 2 Tube End Finish | low-burr, burr-free, brushed, trovalised |

| Ti Alloy Cp Grade 2 Tubes Form | Round, Square, Oval, Rectangular, Coil, "U" Shape, Hydraulic & Honed Tubes |

| Ti Metal Gr 2 Tube Delivery Condition |

|

| Commercially Pure Titanium Tube Packing |

|

| Ti-6AL-4V ELI Titanium Tube Value Added Services | Cut to size, thread, and groove |

| Port | Tianjin, China |

| Stocking distributor of leading Titanium Tube manufacturers |

|

| Ti-6AL-4V ELI Titanium Tube Dimensional Specification | ANSI/ ASME B36.10, B36.19, B2.1 |

| Marking on Titanium Cp Grade 5 Tube |

|

| Application wise types of Titanium Metal Gr 5 Tubes | Ti-6al-4v Titanium Oil Tube, Gas Tube, Fluid Tube, Boiler and ASTM B338 Heat exchanger Tube |

| Weldability | Easily Weldable |

Are you a motorbike or car exhaust fabricator? Or may be an enthusiast looking to save weight in your performance street or race cars. Many Titanium Tube suppliers,exporters, dealers, importers, stockholders, and distributors procure the material from JIADE Overseas and supply this material with higher margins, so contact Oshwin directly to check our price list to get the best price in China. Contact us now for Free quote !!!

Titanium Grade 5 Tubing test procedure involvesMill Test Certificates

EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

Heat Treatment Charts

Chemical Reports

Mechanical Reports

Form A for Generalized System of Preferences (GSP)

Non Destructive Test Reports

Third Party Inspection for Titanium Tubing

NABL Approved Lab Reports

Destructive Test Report

Laboratory Test Certificate from Govt. Approved Lab

100% Radiography Test Report for Ti Grade 2 Tube

Fumigation Certificates

100% inspection according to NACE standards

Raw Materials Certificate

PMI Test Reports

Surface roughness measurement

HS Code Commercial Invoice

Moisture testing

Visual Inspection Reports

| OD 25.4mm X THK 1.2mm X 5005mm Titanium Grade 2 Seamless Tube | INR1600/ Kg |

| Ti-6al-4v EFW Tubing | Ti Alloy Cp Grade 2 Triangle Tubes |

| Ti Alloy Grade 5 ERW Tubing | Cold Drawn Titanium Seamless Tubing |

| TC4 grade Square Tubing | Titanium Grade 5 Hollow Tubes |

| Grade 2 Ti Round Tubes | Re Drawn Grade 5 Titanium Tubing |

| ASTM B861 Gr 5 Tube | Grade 5 Titanium Coil Tubes |

| Grade 2 Titanium Electropolish Tubing | Titanium Grade 2 Instrumentation Tubing |

| CP Ti Grade 5 ERW Tubes | High Pressure Ti Alloy Cp Grade 2 Tube |

| ASTM B861 Grade 5 Capillary Tubing | Titanium Metal Gr 5 Tube |

| Ti Cp Grade 5 Hydraulic Tubing | Ti-6al-4v Titanium Condenser Tubing |

| Ti Metal Gr 2 Rectangular Tubing | Titanium Cp Grade 5 Tube Bends |

| Commercially Pure Titanium Electropolished Tube | CP Titanium Dom Tubing |

| Ti-6AL-4V ELI Titanium Small Diameter Tubing | 12mm Titanium Alloy Grade 5 Tubing |

| Titanium Cp Grade 5 High Pressure Tubes | Ti Alloy Grade 5 Elliptical and Oval Tubes |

| Ti Alloy Grade 5 Round Tubing | Grade 2 Titanium Finned Tubes |

| Ti Alloy Cp Grade 2 Welded Tube | Thin Wall ASTM B338 Titanium Alloy Tubing |

| Titanium Metal Gr 5 Instrument Tubing | Ti Metal Gr 2 Polish Tubing |

| Ti-6al-4v Titanium Square Tube | Commercially Pure Titanium Sanitary Tubing |

| ASTM B338 Titanium Alloy Exhaust Tubing | 1 inch Ti-6AL-4V ELI Titanium Tubing |

| Titanium Grade 5 Gas Tubes | Titanium Grade 2 Coiled Tubing |

| CP Ti Grade 2 Tube | 480-540ºC (900-1000ºF) |

| Ti-6Al-4V, Grade 5 Tubing | 800°F (427°C) |

Ceramic and glass filled linings

Thin Film Engineered Polymer Coatings

Phenol Epoxy

Novolac Epoxy

1000 T Hybrid Epoxy

High Functionality Epoxy - Coating

| DIMENSIONS | WALL | WEIGHT PER | DIMENSIONS | WALL | WEIGHT PER | |

|---|---|---|---|---|---|---|

| (MM) | (MM) | METRE (KG) | (MM) | (MM) | METRE (KG) | |

| 12.7 x 12.7 | 1.20 | 0.44 | 40 x40 | 1.20 | 1.49 | |

| 12.7 x 12.7 | 1.50 | 0.55 | 40 x40 | 1.50 | 1.85 | |

| 15 x 15 | 1.20 | 0.53 | 40 x40 | 2.00 | 2.45 | |

| 15 x 15 | 1.50 | 0.65 | 40 x40 | 3.00 | 3.75 | |

| 20 x 20 | 1.20 | 0.71 | 50 x50 | 1.50 | 2.32 | |

| 20 x 20 | 1.50 | 0.88 | 50 x50 | 2.00 | 3.08 | |

| 20 x 20 | 2.00 | 1.19 | 50 x50 | 3.00 | 4.65 | |

| 25 x 25 | 1.20 | 0.92 | 60 x60 | 2.00 | 3.71 | |

| 25 x 25 | 1.50 | 1.14 | 60 x60 | 3.00 | 5.49 | |

| 25 x 25 | 2.00 | 1.49 | 70 x70 | 3.00 | 6.53 | |

| 25 x 25 | 3.00 | 2.20 | 80 x80 | 2.00 | 4.98 | |

| 30 x 30 | 1.20 | 1.10 | 80 x80 | 3.00 | 7.53 | |

| 30 x 30 | 1.50 | 1.37 | 100 x 100 | 2.00 | 6.40 | |

| 30 x 30 | 2.00 | 1.84 | 100 x 100 | 3.00 | 9.53 | |

| 30 x 30 | 3.00 | 2.72 | ||||

| Gauge | Outside Diameter Tolerance mm | Regular Wall (RW) mm | Thin Wall (TW) mm | Extra Thin Wall (XTW) mm | Ultra Thin Wall (UTW) mm |

| 30 | 0.304 - 0.317 | 0.064 - 0.089 | |||

| 29 | o.330 - 0.342 | 0.064 - 0.089 | |||

| 28 | 0.355 - 0.368 | 0.076 - 0.102 | |||

| 27 | 0.406 - 0.419 | 0.089 - 0.115 | 0.064 - 0.089 | ||

| 26 | 0.457 - 0.469 | 0.089 - 0.114 | |||

| 25 | 0.508 - 0.520 | 0.115 - 0.140 | 0.089 - 0.114 | ||

| 24 | 0.558 - 0.571 | 0.114 - 0.140 | 0.089 - 0.114 | 0.051 - 0.102 | |

| 23 | 0.635 - 0.647 | 0.140 - 0.165 | 0.089 - 0.114 | 0.051 - 0.102 | |

| 22 | 0.711 - 0.723 | 0.140 - 0.165 | 0.096 - 0.121 | 0.077 - 0.102 | 0.051 - 0.102 |

| 21 | 0.812 - 0.825 | 0.140 - 0.165 | 0.102 - 0.127 | 0.051 - 0.102 | |

| 20 | 0.901 - 0.914 | 0.108 - 0.165 | 0.108 - 0.134 | ||

| 19 | 1.054 - 1.079 | 0.166 - 0.216 | 0.102 - 0.140 | 0.070 - 0.108 | |

| 18 | 1.257 - 1.282 | 0.191 - 0.241 | 0.127 - 0.165 | 0.083 - 0.121 | 0.051 - 0.102 |

| 17 | 1.460 - 1.485 | 0.177 - 0.229 | 0.115 - 0.152 | 0.083 - 0.127 | 0.057 - 0.102 |

| 16 | 1.638 - 1.663 | 0.204 - 0.254 | 0.127 - 0.165 | 0.096 - 0.133 | 0.070 - 0.121 |

| 15 | 1.816 - 1.841 | 0.204 - 0.254 | 0.127 - 0.165 | 0.096 - 0.134 | 0.070 - 0.121 |

| 14 | 2.082 - 2.133 | 0.216 - 0.292 | 0.165 - 0.229 | 0.114 - 0.165 | 0.076 - 0.134 |

| 13 | 2.387 - 2.438 | 0.267 - 0.343 | 0.191 - 0.267 | ||

| 12 | 2.743 - 2.749 | 0.267 - 0.321 | |||

| 11 | 3.023 - 3.073 | 0.293 - 0.368 | 0.216 - 0.292 | ||

| 10 | 3.378 - 3.429 | 0.318 - 0.394 | 0.216 - 0.292 |

| N.B | (a) | Any intermediate size can be supplied on request. |

| (b) | Supplied in sufficiently hard condition and also tested for the stiffness. |

| GAUGE | THICKNESS RANGE (INCH) | TYPICAL VALUE (INCH) |

|---|---|---|

| 22 | 0.025 - 0.029 | 0.028 |

| 20 | 0.031 - 0.035 | 0.035 |

| 19 | 0.038 - 0.042 | 0.042 |

| 18 | 0.044 - 0.049 | 0.049 |

| 17 | 0.053 - 0.058 | 0.058 |

| 16 | 0.060 - 0.065 | 0.065 |

| 15 | 0.066 - 0.074 | 0.072 |

| 14 | 0.075 - 0.085 | 0.083 |

| 13 | 0.087 - 0.097 | 0.095 |

| 12 | 0.101 - 0.111 | 0.109 |

| 11 | 0.112 - 0.122 | 0.12 |

| 10 | 0.126 - 0.136 | 0.134 |

| 9 | 0.140 - 0.150 | 0.148 |

| 8 | 0.157 - 0.167 | 0.165 |

| 7 | 0.175 - 0.185 | 0.18 |

Straightness: .030" in 3"

Wall Tolerance +/- 10%

| O.D. INCHES | WALL THICKNESS INCHES | O.D. +/- INCHES |

|---|---|---|

| 1/2" to 1" incl. | .025 to .065 | .005 |

| Over .065 to .134 | .010 | |

| 1 to 1-1/2" incl. | .025 to .065 | .008 |

| Over .065 to .134 | .010 | |

| 1-1/2" to 2" incl. | .025 to .049 | .010 |

| Over .049 to .083 | .011 | |

| Over .083 to .148 | .012 | |

| 2" to 2-1/2" incl. | .032 to .065 | .012 |

| Over .065 to .109 | .013 | |

| Over .109 to .165 | .014 | |

| 2-1/2" to 3-1/2" incl. | .032 to .165 | .014 |

| Over .165 to .220 | .020 | |

| 3-1/2" to 5" incl. | .083 to .165 | .020 |

| Over .165 to .220 | .025 |

We cut Titanium welded tubing to your exact dimension

Grade 2 Titanium Tubing can be polished per customer specification

Beveling Titanium Grade 5 tubes

Heat treating & annealing

Honing/ turning process for Titanium Tube

Additional positive material identification (PMI) testing if required

Ultrasonic Testing (UT)

ASTM B338 - Seamless and welded titanium alloy tubes for condensers & heat exchangers

| ELEMENT | TITANIUM | NITROGEN | CARBON | HYDROGEN | IRON | OXYGEN | RESIDUALS (EACH) | RESIDUALS (TOTAL) |

|---|---|---|---|---|---|---|---|---|

| % | Balance | 0.03 max | 0.08 max | 0.015 max | 0.30 max | 0.25 max | 0.1 max | 0.4 max |

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade5 | 90 min | - | 0.25 max | - | - | 0.2 max | 6 min | 4 min |

| 0.2% PROOF STRESS | TENSILE STRENGTH | ELONGATION | |

|---|---|---|---|

| MPA | MPA | % | |

| Annealed | 275-450 | 345 | 20 |

DENSITY | MELTING RANGE | MODULUS OF ELASTICITY (TENSION) | SPECIFIC HEAT | MEAN COEFFICIENT OF EXPANSION | THERMAL CONDUCTIVITY | ELECTRICAL RESISTIVITY |

|---|---|---|---|---|---|---|

kg/m3 | °C | GPa | J/kg. °C | x10 -6 / °C | W / m. °C | micro-ohm.m |

| 4,507 | 1668± 10 | 103 | 519 | 8.41 | 11.4 | 0.420 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr. 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi - 138000 , MPa - 950 | Psi - 128000 , MPa - 880 | 14 % |

| ALLOY | WERKSTOFF NR. | UNS |

| Titanium Gr 2 | R50400 | 3.7035 |

| Titanium Gr. 5 | 3.7165 | N56400 |

Q1. Where is your factory ?

A1: Our company's processing center is located in Zhejiang, China.

Which is well equipped with kinds of machines, such as laser cutting machine,mirror polishing machine and so on.We can provide a wide range of personalized services according to the customers' needs.

Q2. What are your company's main products ?

A2: Our main products are stainless steel plate,aluminum ,copper etc.

Q3. How do you control quality ?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company ?

A4: We have many professionals, technical personnel, more competitive prices and best after-dales service than other companies.

Q5. How many coutries you already exported ?

Send Inquiry to This Supplier

You May Also Like

-

ASTM 201 304 304L 321 316 316L 904L Seamless/Galvanized/Carbon Steel/Stainless/ERW/Rectangular/Hot Dipped Galvanized Steel Tube PipeUS$ 1 - 10000MOQ: 1 Ton

-

Factory Supply Grade 1/Gr. 1/Zta1/JIS H4600 Tr270c Titanium Bar/Rod Stock Titanium Wholesale Price Per KgUS$ 20MOQ: 1 Meter

-

Gr1/Gr2/Gr3/Gr4/Gr5/Gr9/Gr23 High Purity and Good Roundness Titanium Alloy for Medical Aerospace IndustryNegotiableMOQ: 100000 Tons

-

High Quality Gr. 23 Class 60e Titanium AlloyNegotiableMOQ: 100000 Tons

-

904L C-276 C22 B3 Alloy/Titanium/Hastelloy/Nickel Alloy/Monel/Welding /Seamless/Stainless/Aluminum/Copper/Carbon/Steel PipeNegotiableMOQ: 100000 Tons

-

304 316 316L 201 430 410 Black Titanium Titanium Alloy Temperature-Resistant Stainless Steel PipeNegotiableMOQ: 100000 Tons

-

Tin Corten Ss400 High Strength Wear Checkered A36 304 Ms Hot Rolled Mild Galvanized Stainless Carbon Steel Brass Copper Titanium Alloy Plate PriceNegotiableMOQ: 100000 Tons

-

304 316 310S A36 Ss400 SPCC SGCC Cold Rolled/Hot Rolled/Stainless/Titanium/Wear Resistant/Carbon Hastelloy/Monell Alloy/AluminumNegotiableMOQ: 100000 Tons

-

Corrosion Resistant Gr1 Gr2 Gr3 Gr4 Gr5 Ritanium Plate High Strength Titanium Alloy Plate Titanium Plate ASTM B265 AMS 4911NegotiableMOQ: 100000 Tons

-

AMS 4963 AMS 4965 AMS 4967 AMS 4985 6al-4V Eli Titanium Sheet 0.3mm Thick AMS 4914 Titanium Alloy Sheet Titanium Plate PriceNegotiableMOQ: 100000 Tons