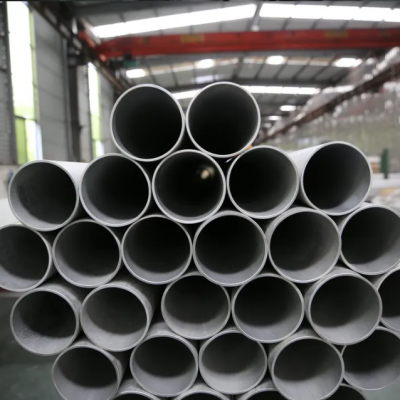

ASTM 304 316L Carbon Square Seamless Galvanized Stainless Steel Pipe Tube, O. D. 3/8"-100", Length 6000mm

| Property | Nickel-based Alloy Steel Strips | Nickel-based Alloy Steel Sheets |

| Material Composition | Primarily contains nickel along with iron, chromium, and other alloying elements. | Primarily contains nickel with iron, chromium, molybdenum, and sometimes other elements like cobalt or titanium. |

| Thickness | Generally thinner (typically less than 5 mm) and used for applications requiring flexibility and precision. | Can be thicker (ranging from 1 mm to several cm) for structural and industrial applications. |

| Applications | Used in manufacturing components like electrical contacts, heat exchangers, and industrial equipment. | Used in the production of structural components, turbine blades, aerospace parts, and chemical processing equipment. |

| Mechanical Properties | High strength, good ductility, and resistance to corrosion and heat. | Excellent mechanical properties including strength, toughness, and resistance to high-temperature environments. |

| Corrosion Resistance | Highly resistant to oxidation and corrosion in extreme environments (e.g., marine, chemical, and high-temperature conditions). | Exceptional resistance to corrosion, especially in acidic or high-temperature environments, often used in harsh industrial environments. |

| Thermal Resistance | Can withstand high temperatures, typically up to 800°C or higher. | Excellent thermal stability, often used in applications with temperatures exceeding 1000°C. |

| Forming & Fabrication | Can be easily cold-rolled or annealed into thin strips, offering versatility in manufacturing. | Typically hot-rolled or cold-rolled, and may require advanced techniques for shaping due to their thickness and material strength. |

Key Features of Inconel Alloys:

Corrosion Resistance: Exceptional resistance to a wide range of acids, including sulfuric, hydrochloric, and phosphoric acids.

High-Temperature Resistance: They perform well in high-temperature environments, maintaining strength and resisting oxidation.

Mechanical Strength: Inconel alloys exhibit high tensile strength and durability under both high temperature and pressure.

Inconel Sales Company - Frequently Asked Questions (FAQ)

1. How do I choose the right Inconel material for my needs?

When selecting Inconel materials, consider the following factors:

Operating Environment: Including temperature, corrosive media, oxidation conditions, etc.

Corrosion Resistance: Different Inconel alloys have varying resistance to different types of corrosion (acidic, chlorides, oxidation, etc.).

Mechanical Properties: Including tensile strength, hardness, etc., depending on the specific workload of the application.

If you're unsure about which alloy to choose, our technical support team can assist you with professional recommendations based on your requirements.

2. What specifications are available for your Inconel products?

We offer a wide range of Inconel products, including plates, pipes, bars, wires, and customized products. Specifications include various thicknesses, diameters, lengths, etc., to meet diverse customer needs.

3. What is the delivery time for Inconel products?

For standard stock items, the delivery time is typically 3-7 working days. For customized or specially processed products, delivery time may vary and is generally 2-4 weeks. Specific delivery times can be confirmed based on order quantities and production schedules.

4. How do you guarantee the quality of your Inconel products?

All of our Inconel products are sourced from reliable manufacturers and strictly adhere to international quality standards. Each batch of materials comes with detailed quality inspection reports and material certificates to ensure that the products meet performance and quality standards.

5. Do you offer technical support and consulting services?

Yes, we provide free technical support services. Our engineering team can assist with material selection, processing techniques, performance testing, and more. Whether it's product selection or engineering design, we can provide professional consulting services.

6. How can I get a quote?

You can request a quote through the following methods:

Submit a quote request form on our website

Call our sales hotline

Contact us via email Please provide details such as the alloy type, specifications, quantity, and delivery location to receive an accurate quote.

7. Do you support international shipping?

Yes, we offer worldwide shipping. Our experienced logistics team can assist with various international shipping issues, including transportation options, customs handling, and destination requirements.

8. What payment methods do you accept?

We accept various payment methods, including bank transfers, credit card payments, PayPal, and more. The specific payment method can be confirmed based on the order amount and customer preferences.

9. Do you offer returns or exchanges?

Due to the customized or specialty nature of Inconel materials, our return and exchange policy is strict. Standard stock products can be returned or exchanged if they are unused and unprocessed. Please confirm the return/exchange conditions and process with our sales team before placing an order.

10. What certifications or documentation do you provide?

We can provide the following certifications and documents:

Material inspection reports

Material certificates

Compliance certificates (e.g., ISO 9001 certification)

Other certification documents as required by the customer

Send Inquiry to This Supplier

You May Also Like

-

Advanced Technology Selling ASME SA312 Titanium Ta3 Ta9 Alloy Steel TubeNegotiableMOQ: 100000 Tons

-

OEM&ODM Titanium Alloy Condensers Tubes, Heat Exchanger Titanium Pipe/Tube for Nuclear Power Plants, GeneratorsNegotiableMOQ: 100000 Tons

-

ASTM B861 Gr9 Titanium Alloy Pipe/Tube ManufacturerNegotiableMOQ: 100000 Tons

-

Ti-6al-4V Titanium Square Tube Size and Weightastm B338 Titanium Alloy Capillary Tube Size Chartti Metal Gr 2 Exhaust TubingNegotiableMOQ: 100000 Tons

-

Customized Size Superelastic Nitinol Alloy Tube Medical Grade ASTM F2063 Nickel Titanium Capillary Shape Memory Alloy TubeNegotiableMOQ: 100000 Tons

-

China Expless High Quality Ti Gr. 3 Titanium & Titanium Alloy Pipe / TubeNegotiableMOQ: 100000 Tons

-

High Temperature Resistant Titanium Plate Ta1 Gr1 for Electronics ManufacturingUS$ 2550 - 3900MOQ: 1 Ton

-

Drill API 5L 304 316L Oil Ms 316 Mild Casing ERW Gi Square Spiral Welded Galvanized Carbon Stainless Copper Nickel Titanium Alloy Seamless Steel PipeUS$ 1 - 10000MOQ: 1 Ton

-

ASTM Round/Square/Rectangular Ss 201 304/304L 316/316L 904 430 6061 Brushed/Mirror Polished Seamless/Welded Stainless Steel Tube Pipe PriceUS$ 1 - 10000MOQ: 1 Ton

-

ASTM 201 304 304L 321 316 316L 904L Seamless/Galvanized/Carbon Steel/Stainless/ERW/Rectangular/Hot Dipped Galvanized Steel Tube PipeUS$ 1 - 10000MOQ: 1 Ton