BS1387 Galvanized Scaffolding Tube 48mm Schedule 40 Standard Length Gi Steel Pipe Price Philippines

ption

What you are looking for is

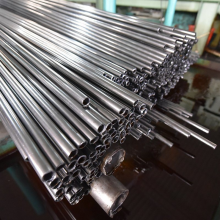

ISO 2037 DIN 11850 ASTM A270 SUS 201 304 304L 309 316 316L Welded/Seamless Tube Stainless Steel Milk Pipe

If you are still suffering from the inconvenience caused by the corrosion and cracking of the pipeline, or you are suffering from the failure to find a suitable stainless steel sanitary tube supplier. Please read the following content in 3 minutes. I hope it can be helpful for you.

Guangdong Yaolong Metal Technology Co.,Ltd is located in Foshan City,China.It is a modern enterprise which integrates R&D,design,production and distribution,specializing in the field of stainless steel & aluminum light poles,stainless steel & aluminum flagpoles,stainless steel bollard ,stainless steel welded pipes and fittings.

Our stainless steel weld pipes and fittings are not only sold to domestic markets,but also exported to many countries like Australia,Canada,Germany,Holland,Russia,Saudi Arabia,Spain,the United Kingdom,the United States,UAE,etc.

"The pursuit of quality is our persistence"

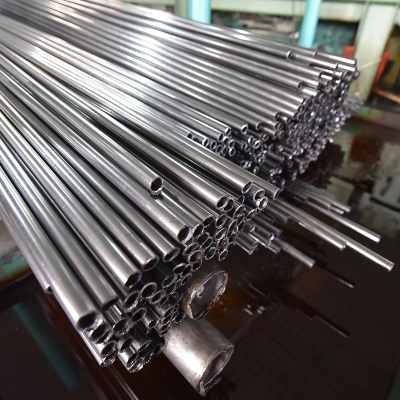

We chose austenitic stainless steels from BAOSTEEL or TISCO as raw materials. Because these raw materials have high-quality properties, the effects after surface treatment will be more diversified. Pickling, polishing, mirror polishing, satin brushing, powder coating, you can choose the effect you want according to actual needs, we will try our best to help you complete.

"Stainless steel sanitary pipes with a outer diameter of 25.40mm to 101.6mm meters can meet 80% of the market requirements"

The outer diameter range of the stainless steel food grade tubes that our company has currently made is 15.88 mm to 2000 mm, if you need a bigger one, we can also complete it.

"The products we do the most are round pipes , rectangular pipes and square pipes. In this respect, our production line and workmanship are very mature."

If you need a profiled tube, please consult us with engineering drawings with parameters. Our engineers will analyze the technical difficulties and discuss cooperation plans with you.

|

Material | Stainless Steel 304/304L/316/316L |

Shape | Round / Square / Rectangle |

Production Standards | ASTM A270 , AS 1528.1 , EN 10357 , DIN 11850 ,ISO 2037 , JIS G3447, KS D 3585 and so on. |

Outer Diameter | 16mm - 2000mm ; |

Thickness | 0.8mm - 20 mm ; |

Length | 6 Meters - 18.3 Meters ; As customers' request ; |

Tolerance | According to the Standard , +/-10% Commonly ; |

Surface Treatment | 180#, 320#, 400# Satin / Hairline, Bright Anneal, Pickle,400#, 500#, 600# or 800# Mirror finish |

Application | Suitable For Industries With High Hygiene Requirements Such As Beer, Beverage, Milk, Pharmaceuticals, Etc. |

Test | Flaring test ; Flattening test ; Bending Test ; Hydraulic Test ; Eddy Current test |

Design | OEM / ODM / Customized |

Certificate | ISO9001 ; ISO14001; ISO 18001; TUV ; |

AS 1528.1 | |||||

Size OD | Tolerance of OD | Wall Thickness | Tolerance on Wall Thickness | Tolerances on Length | Weight KG/M |

12.70 | +/- 0.1 | 1.20 | +/- 10.0% | +3, -0 | 0.344 |

15.88 | +/- 0.1 | 1.20 | +/- 10.0% | +3, -0 | 0.439 |

19.05 | +/- 0.1 | 1.20 | +/- 10.0% | +3, -0 | 0.534 |

25.40 | +/- 0.1 | 1.20 | +/- 10.0% | +3, -0 | 0.723 |

25.40 | +/- 0.1 | 1.60 | +/- 10.0% | +3, -0 | 0.949 |

38.10 | +/- 0.1 | 1.20 | +/- 10.0% | +3, -0 | 1.103 |

50.80 | +/- 0.1 | 1.60 | +/- 10.0% | +3, -0 | 1.455 |

50.80 | +/- 0.1 | 1.20 | +/- 10.0% | +3, -0 | 1.483 |

63.50 | +/- 0.1 | 1.60 | +/- 10.0% | +3, -0 | 1.961 |

76.20 | +/- 0.1 | 1.60 | +/- 10.0% | +3, -0 | 2.467 |

101.60 | +/- 0.1 | 1.60 | +/- 10.0% | +3, -0 | 2.973 |

3A ASTM A270 | |||||

Size OD | Tolerance of OD | Wall Thickness | Tolerance on Wall Thickness | Tolerances on Length | Weight KG/M |

3/4 " (19.1 mm) | +/-0.005" (0.13 mm) | 0.065" (1.65 mm) / 0.049" (1.25 mm) | +/- 10.0% | +1/8" (3.18 mm) | 0.7218 |

1" (25.4 mm) | +/-0.005" (0.13 mm) | 0.065" (1.65 mm) / 0.049" (1.25 mm) | +/- 10.0% | +1/8" (3.18 mm) | 0.9824 |

1-1/4" (31.8 mm) | +/-0.008" (0.20 mm) | 0.065" (1.65 mm) | +/- 10.0% | +1/8" (3.18 mm) | 1.2412 |

1-1/2" (38.1 mm) | +/-0.008" (0.20 mm) | 0.065" (1.65 mm) / 0.049" (1.25 mm) | +/- 10.0% | +1/8" (3.18 mm) | 1.5078 |

2" (50.8 mm) | +/-0.008" (0.20 mm) | 0.065" (1.65 mm) / 0.049" (1.25 mm) | +/- 10.0% | +1/8" (3.18 mm) | 2.0031 |

2-1/2" (63.5 mm) | +/-0.010" (0.25 mm) | 0.065" (1.65 mm) | +/- 10.0% | +1/8" (3.18 mm) | 2.5585 |

3" (76.2 mm) | +/-0.010" (0.25 mm) | 0.065" (1.65 mm) | +/- 10.0% | +1/8" (3.18 mm) | 3.0797 |

4" (101.6 mm) | +/-0.015" (0.38 mm) | 0.065" (1.65 mm) / 0.083" (2.11 mm) | +/- 10.0% | +1/8" (3.18 mm) | 5.2628 |

ISO 2037 | |||||

Size OD | Tolerance of OD | Wall Thickness | Tolerance on Wall Thickness | Tolerances on Length | Weight KG/M |

21.30 | +/- 0.13 | 1.00 | +/-10.0% | +3.18 -0 | 0.506 |

25.00 | +/- 0.13 | 1.20 | +/-10.0% | +3.18 -0 | 0.712 |

25.00 | +/- 0.13 | 1.60 | +/-10.0% | +3.18 -0 | 0.933 |

33.70 | +/-0.20 | 1.20 | +/-10.0% | +3.18 -0 | 0.972 |

33.70 | +/-0.20 | 1.60 | +/-10.0% | +3.18 -0 | 1.280 |

38.00 | +/-0.20 | 1.20 | +/-10.0% | +3.18 -0 | 1.100 |

38.00 | +/-0.20 | 1.60 | +/-10.0% | +3.18 -0 | 1.451 |

40.00 | +/-0.20 | 1.20 | +/-10.0% | +3.18 -0 | 1.160 |

40.00 | +/-0.20 | 1.60 | +/-10.0% | +3.18 -0 | 1.531 |

51.00 | +/-0.20 | 1.20 | +/-10.0% | +3.18 -0 | 1.490 |

51.00 | +/-0.20 | 1.60 | +/-10.0% | +3.18 -0 | 1.970 |

63.50 | +/-0.25 | 1.60 | +/-10.0% | +3.18 -0 | 2.467 |

70.00 | +/-0.25 | 1.60 | +/-10.0% | +3.18 -0 | 2.730 |

76.10 | +/-0.25 | 1.60 | +/-10.0% | +3.18 -0 | 2.970 |

88.90 | +/-0.25 | 2.00 | +/-10.0% | +3.18 -0 | 4.330 |

101.60 | +/-0.38 | 2.00 | +/-10.0% | +3.18 -0 | 4.983 |

1.The inner wall of the our pipeline is smooth and not easy to scale, so it is not easy to be infected by bacteria, reduce coliform bacteria poisoning and other hazards.And it ensures the safety of drinking. .

2.Stainless steel tube is 3 times stronger than steel pipe and 8-10 times stronger than plastic pipe, which is not easy to leak. Stainless steel pipes are also resistant to damage in earthquakes because they are impact resistant.

3.Stainless steel tubing has low thermal conductivity, the thermal insulation performance is five times that of copper pipe, so it is also suitable for application in high temperature fluid.

"One-stop shopping, reducing the procurement process."

We have extensive experience in providing stainless steel welding pipes and fittings for more than 118 project contractors and stockists.

We has a complete series of advanced equipment from Germany, Japan, Italy and France, including plasma auto-welding machine, polishing facility, online inner bead removed and online bright anneal facilities etc.

The tubes, produced by our facilities, are mainly applied for mechanical industries in boiler, heat exchanger, condenser, heater. After inner and outer polished, tubes are widely used in sanitary industries of food, beverage, biology, pharmacy, beer and electron. Large diameter fluid conveying welded pipes, ranging 325-2000 mm, are commonly used in oil, chemical.

We have three factories that can be used to make stainless steel pipes. You don't have to worry about the production cycle at all.We will formulate a production plan according to the delivery time to ensure that it can be completed on time.

We have a team of professional designers, engineers and skillful welders.We can make products that meet your requirements.

Our annual production capability is more than 15,000 tons. We has been vertified and recognized as material manufacturer according to AD 2000-Merkblatt W0, PED 2014/68/EU, and TUV ISO 9001:2015 International Quality System.

The good quality and professional service help us gain many good reputation all over the world.

Q1:Are you trading company or manufacturer? | We are the professional manufacturer with 3 factories. Specializing in producing welded stainless steel tube and pipe fittings, stainless steel bollard for over 13 years. |

Q2:How long is your delivery time? | It is according to quantity. Generally it is 30 days. |

Q3:Can you provide us sample, is it free or need to pay? | If you don't need to print your logo or other artwork on the products, we will not charge any cost, just tell us your freight collect account like Fedex, DHL, TNT. If you don't have, we need to charge Express fee properly. |

Q4:Can I get your best price? | Our goal is to provide you the best price with great quality assured in a long run. Please leave your contact information for the best quotations, we will get back to you with the best solutions as soon as we can. |

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Tubes, ASTM A249, TP304. TP304L, Tp316L, Tp317L, Tp310s, Tp316tiNegotiableMOQ: 100000 Tons

-

ASTM Welded Pipe 201 304L 316L 321 420 430 904 Stainless Steel TubeNegotiableMOQ: 100000 Tons

-

Factory Wholesale Full Hard S31803 S32205 Duplex Grade Standard Stainless Steel Pipe Heat Resistance Customized TubeNegotiableMOQ: 100000 Tons

-

ASTM 304 316 316L 202 Carbon Seamless Galvanized Square Stainless Steel Tube, 6mm-2500mm O. D., 1mm-150mm ThickNegotiableMOQ: 100000 Tons

-

TUV ISO 304/304L 304h 321 321H 316 316L 316h Polished Seamless Stainless Pipe Steel Products Square Round Rectangular TubeUS$ 4899MOQ: 25 Tons

-

ASTM Ss 201 304 304L 316 316L 430 Stainless Steel Tube Seamless or Welded Round/Square/Rectangular/Hex/Oval TubeNegotiableMOQ: 100000 Tons

-

ASTM A213 Tp904L/1.4539/N08904 Stainless Steel Seamless Tube for Furnace ComponentsNegotiableMOQ: 100000 Tons

-

AISI304 316 Stainless Steel Welding Pipes With Polishing Surface for Building DecorationNegotiableMOQ: 100000 Tons

-

Philippine Warehouse Ready Stock! ASTM A554 Decorative Pipes - Same Day Delivery to QC CityNegotiableMOQ: 100000 Tons

-

Cost-Effective 321 Stainless Steel Pipes for Long-Term UseNegotiableMOQ: 100000 Tons