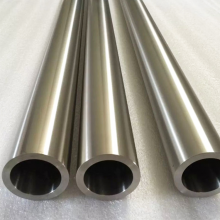

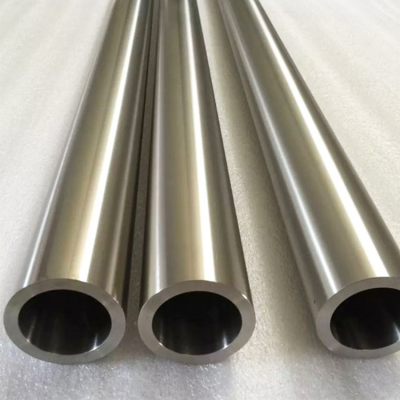

Cold Drawn Factory Manufacturer Supplier Directly Sale Alloy Seamless Steel Pipe

(UNS N10665) is a nickel-molybdenum alloy known for its excellent resistance to a wide range of aggressive environments, particularly in reducing acids such as hydrochloric acid and sulfuric acid. It is a member of the Hastelloy family and is widely used in industries that require strong resistance to corrosion, especially in applications that involve highly corrosive, reducing environments.

Hastelloy UNS N10665 is also known as Hastelloy B-2. It is a high-performance, nickel-molybdenum alloy designed primarily for applications that require excellent resistance to reducing acids, especially hydrochloric acid and sulfuric acid, as well as resistance to chloride-induced corrosion. Its outstanding properties make it ideal for chemical processing and other industries where exposure to aggressive, corrosive environments is common.

Key Features

Corrosion Resistance:

Outstanding resistance to hydrochloric acid in all concentrations and temperatures.

Resists stress corrosion cracking, pitting, and crevice corrosion.

Performs well in environments containing acetic, sulfuric, and phosphoric acids.

High Molybdenum Content:

Molybdenum is the primary alloying element that enhances corrosion resistance in reducing environments.

Limitations:

Not recommended for use in strongly oxidizing media.

Care must be taken to avoid exposure to oxidizing agents such as ferric or cupric salts, as they can cause rapid corrosion.

Temperature Range:

Excellent thermal stability and can be used in temperatures up to about 1000°F (537°C).

It can withstand thermal cycling but must avoid prolonged exposure to extreme high temperatures, as it can lead to loss of ductility.

Due to its superior corrosion resistance, Hastelloy B-2 is commonly used in industries dealing with:

Chemical processing equipment, such as reactors, heat exchangers, and vessels.

Piping systems for highly corrosive chemicals.

Components for pickling systems.

Pollution control (scrubbers, ducts, and stack liners).

Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Ltd. specializes in stainless steel seamless tubes, with a range of 6-325mm in diameter. The materials include 304, 321, 316L, 2205, etc. Our stainless steel products are widely used in industries such as petroleum, chemical engineering, chemical fiber, metallurgy, medical machinery, papermaking, thermal insulation and refrigeration, mechanical equipment, food, power, water conservancy, construction, submarine engineering, marine shipping, and environmental protection. Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Ltd. is a strong company that values credit, adheres to contracts, and guarantees product quality. With the business feature of multiple varieties and the principle of selling at a small profit but a large volume, we have won the trust of many customers. All the staff of our company sincerely welcome your inquiries!

Hastelloy grades: Hastelloy C276, Hastelloy C22, Hastelloy C-2000, Hastelloy C-4, Hastelloy C, Hastelloy B, Hastelloy B-2, Hastelloy B-3, Hastelloy X, Hastelloy G-30, Hastelloy G-35, etc.

| Hastelloy | ||||||||||||

| Grade | Ni | Cr | Fe | Mo | W | Co | C | Mn | Si | S | P | Other |

| C-276 | Rom | 15-16.5 | 4-7 | 15-17 | 3-4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.001 | 0.015 | v0.1-0.3 |

| C-22 | 56-59 | 20-22.5 | 2-6 | 12.5-14.5 | 2.5-3.5 | 2.5 | 0.015 | 0.5 | 0.08 | 0.02 | v0.35 | |

| C-2000 | Rom | 22-24 | 3 | 15-17 | 2 | 0..01 | 0.5 | 0.06 | 0.01 | 0.025 | Al0.5 Cu1.6 | |

| B-2 | Rom | 0.4-0.7 | 1.6-2 | 26-30 | 1 | 0.01 | 1 | 0.08 | 0.01 | 0.02 | Cu0.5 | |

| B-3 | 64 | 1-3 | 1-3 | 27-32 | 3 | 3 | 0.01 | 3 | 0.1 | 0.01 | 0.03 | v0.2 Al0.5 Ti0.2 Cu0.2 |

| G-30 | Rom | 28-31.5 | 13-17 | 4-6 | 1.5-4 | ≤5 | 0..03 | ≤2 | ≤1 | ≤0.02 | ≤0.04 | Nb/Ta0.3-1.5 Cu1-2.4 |

| X | Rom | 20.5-23.5 | 17-20 | 8-10 | 0.2-1 | 0.5-2.5 | 0.05-0.15 | 1 | 1 | 0.015 | 0.025 | Al0.5 Ti0.15 B0.005 |

| C-4 | Rom | 14-18 | 3 | 14-17 | 2 | 0.015 | 1 | 0.08 | 0.7 | 0.04 | Ti0.7 | |

| G-35 | 8-10 | 5 | 33 | 2 | 0.03 | 2-3 | 1.5 | 1 | 2 | 0.02 | Cu0.04 | |

| C | Rom | 14.5-17.5 | 4-7 | 15-17 | 3-4.5 | 0.03 | 1 | 0.03 | 0.04 | |||

| Hastelloy | Density g/cm3 | Melting point ºC | Elongation A5 % | Tensile Strength Rm N/mm2 | Yield Strength RP0.2N/mm2 |

| C-276 | 8.9 | 1325-1370ºC | 62 | 758 | 363 |

| C-22 | 8.9 | 1325-1370ºC | 40 | 690 | 283 |

| C-2000 | 8.5 | 1399ºC 2550°F | 45 | 690 | 283 |

| B-2 | 9.2 | 1330-1380ºC | 40 | 745 | 325 |

| B-3 | 9.22 | 1370-1418ºC | 40 | 760 | 350 |

| G-30 | 8.22 | 1399ºC 2550°F | 62 | 524 | 200 |

| X | 8.3 | 1260-1355ºC | 30 | 690 | / |

| C-4 | 8.64 | 399°C 2550°F | 40 | 690 | 280 |

| G-35 | 8.22 | 1370-1400ºC | / | / | / |

| C | 8.94 | 1330-1380 ºC | 40 | 690 | 310 |

1. What is Hastelloy?

Hastelloy is a high-performance corrosion-resistant alloy widely used in industries such as chemical processing, aerospace, marine, and energy, especially in extreme temperature and corrosive environments. Its main components include nickel, molybdenum, chromium, and other metal elements.

2. What types of Hastelloy alloys do you sell?

We sell a variety of Hastelloy alloys, including but not limited to:

Hastelloy C-276

Hastelloy C-22

Hastelloy B-2

Hastelloy X

Hastelloy G-30 Each alloy has different corrosion resistance properties and high-temperature characteristics, suitable for various industrial applications.

3. How do I choose the right Hastelloy material for my needs?

When selecting Hastelloy materials, consider the following factors:

Operating Environment: Including temperature, corrosive media, oxidation conditions, etc.

Corrosion Resistance: Different Hastelloy alloys have varying resistance to different types of corrosion (acidic, chlorides, oxidation, etc.).

Mechanical Properties: Including tensile strength, hardness, etc., depending on the specific workload of the application.

If you're unsure about which alloy to choose, our technical support team can assist you with professional recommendations based on your requirements.

4. What specifications are available for your Hastelloy products?

We offer a wide range of Hastelloy products, including plates, pipes, bars, wires, and customized products. Specifications include various thicknesses, diameters, lengths, etc., to meet diverse customer needs.

5. What is the delivery time for Hastelloy products?

For standard stock items, the delivery time is typically 3-7 working days. For customized or specially processed products, delivery time may vary and is generally 2-4 weeks. Specific delivery times can be confirmed based on order quantities and production schedules.

Send Inquiry to This Supplier

You May Also Like

-

Nickel Alloy Uns N06686 2.4606 Gh4698 Round Rod/Pipe Advanced Materials for High TemperaturesNegotiableMOQ: 100000 Tons

-

Ta1 Pure Titanium Plate Ta2 Tc4 Titanium Tube Rod Pipe Rolled Titanium Material With Good Plasticity Easy Processing FormingNegotiableMOQ: 100000 Tons

-

ASTM 304 316L Carbon Square Seamless Galvanized Stainless Steel Pipe Tube, O. D. 3/8"-100", Length 6000mmNegotiableMOQ: 100000 Tons

-

Gr1 /Zta1/JIS H4600 Tr270c High Purity and High Quality Titanium Strips/Coil Has Good Strength and Corrosion Resistance Industrial MedicalUS$ 990 - 1250MOQ: 1 Ton

-

GB/T700 Q235A ASTM A283m JIS G3101 Ss440 A36 Hot Rolled Carbon Steel CoilUS$ 990 - 1250MOQ: 1 Ton

-

GB/T700 Q235A/ASTM A283m Gr. D JIS/G3101/Ss440 Hot Rolled Steel Sheets CoilUS$ 2550 - 3900MOQ: 1 Ton

-

GB/T700 Q235A ASTM A283m Gr. D JIS G3101 Ss440 Hot Rolled Steel Sheets CoilUS$ 2550 - 3900MOQ: 1 Ton

-

High Temperature Resistant Titanium Plate Ta1 Gr1 for Electronics ManufacturingUS$ 2550 - 3900MOQ: 1 Ton

-

Advanced Technology Selling ASME SA312 Titanium Ta3 Ta9 Alloy Steel TubeNegotiableMOQ: 100000 Tons

-

OEM&ODM Titanium Alloy Condensers Tubes, Heat Exchanger Titanium Pipe/Tube for Nuclear Power Plants, GeneratorsNegotiableMOQ: 100000 Tons