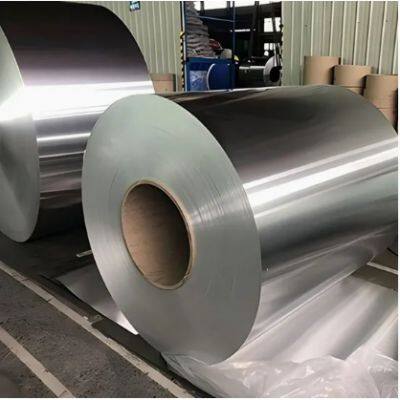

Uns S32750/ASTM A240 Duplex Steel Coils for Heat Exchangers 2507 Stainless Steel Strip

ZHEJIANG ZHONGZHENG STAINLESS STEE MANUFACTURING CO., LTD is a special stainless steel manufacturer with 20 years of manufacturing experience.

Stainless steel Super Duplex 2507 is designed to handle highly corrosive conditions and situations were high strength is required. High molybdenum, chromium and nitrogen content in Super Duplex 2507 help the material withstand pitting and crevice corrosion. The material is also resistant to chloride stress corrosion cracking, to erosion corrosion, to corrosion fatigue, to general corrosion in acids. This alloy has good weldability and very high mechanical strength.

▪ Offshore platforms, heat exchangers, process and service water systems, fire-fighting systems, injection and ballast water systems

▪ Chemical process industries, heat exchangers, vessels, and piping

▪ Desalination plants, high pressure RO-plant and seawater piping

▪ Mechanical and structural components, high strength, corrosion-resistant parts

▪ Power industry FGD systems, utility and industrial scrubber systems, absorber towers, ducting, and piping

2507 -S32750-SAF2507-00Cr25Ni7Mo4N

EURONORM...... 1.4410 - X2 Cr Ni MoN 25.7.4

AFNOR......... Z3 CN 25.06 Az

Preheating of 2507 is not necessary except to prevent condensation on cold metal. The interpass weld temperature should not exceed 300°F or the weld integrity can be adversely affected. The root should be shielded with argon or 90% N2/10% H2 purging gas for maximum corrosion resistance. The latter provides better corrosion resistance.

Chemical Composition

| Element | Content (%) |

| Chromium, Cr | 24 - 26 |

| Nickel, Ni | 6 - 8 |

| Molybdenum, Mo | 3 - 5 |

| Manganese, Mn | 1.20 max |

| Silicon, Si | 0.80 max |

| Copper, Cu | 0.50 max |

| Nitrogen, N | 0.24 - 0.32 |

| Phosphorous, P | 0.035 max |

| Carbon, C | 0.030 max |

| Sulfur, S | 0.020 max |

| Iron, Fe | Balance |

| Ultimate Tensile Strength, ksi | 116 min. |

| 0.2% Offset Yield Strength 0.2%, ksi | 80 min. |

| 0.1% Offset Yield Strength 0.2%, ksi | 91 min. |

| Elongation in 2 inches, % | 15 min. |

| Hardness Rockwell C | 32 max. |

| Impact Energy, ft.-lbs. | 74 min. |

| 2507/S32750 stainless steel coil sizes and specifications | |

| Grade | 2507/S32750 |

| Cold rolled stainless steel coil | Thickness: 0.3mm- 3.0mm, Width: 1000mm - 2000mm,Surface: 2B/BA/SB/8K/HL/1D/2D etc |

| Hot rolled stainless steel coil | Thickness: 3.0mm - 16mm, Width: 1000mm - 2000mm Surface: No.1/pickling |

| Standard | ASTM A240/A480, ASTM B688, ASTM B463/SB463, ASTM B168/SB168, ASTM B443/SB443/B424/SB424B625/SB625 B575/SB575, JIS G4303, BS 1449, DN17441, G430 |

Send Inquiry to This Supplier

You May Also Like

-

Custom ASTM A276/Uns S32750/ASTM A240 Stainless Steel Plate for Desalination Equipment Duplex Steel 2507 SheetUS$ 25 - 35MOQ: 100 Kilograms

-

ASTM A276/ASTM A479/Uns S32750 Duplex Steel Sheet for Marine Industry and Shipbuilding F53 Stainless Steel PlateUS$ 25 - 35MOQ: 100 Kilograms

-

S32750 Stainless Steel Plate for Oil Equipment 2507 Duplex Steel SheetUS$ 25 - 35MOQ: 100 Kilograms

-

ASTM A240 Ss 201 202 304 316 409 410 430 J1 J2 J3 S32750 Cold Rolled 2b Ba 8K Mirror Hairline Surface Mill Edge Polished Stainless Steel Sheet CoilUS$ 2500 - 3500MOQ: 1 Ton

-

S32750, 2507, S25073 Stainless Steel Plate. ASTM A240 StandardUS$ 2500 - 3500MOQ: 1 Ton

-

Martensitic Stainless Steel 309S 310S 904L 2205 0.3-100mm 2507 1.4410 ASTM A240 S32750 2507 Austenitic Stainless Steel CoilUS$ 2500 - 3500MOQ: 1 Ton

-

Acero Inoxidable AISI 2507/Uns S32750/Cr25ni7mo4n/F53/1.4410/ASTM A240/A276US$ 2600 - 6900MOQ: 2 Tons

-

Hot off The Shelf Acero Inoxidable AISI 2507/Uns S32750/Cr25ni7mo4n/F53/1.4410/ASTM A240/A276 Hot Rolled Cold Rolled Mirror Finish SheetUS$ 3000 - 6900MOQ: 1 Ton

-

Hot Sales 3re60 S21953 ASTM A240 Ss 304 316 321 310S 309S 430 Steel Plate 1- 6mm Aluminum/ Titanium/Inconel/Magnesium/ Stainless Steel SheetUS$ 2600 - 6900MOQ: 2 Tons

-

Golden Supplier Precise Stainless Steel Coils/strips/plates 304 316 310S Cold Rolled Ultra ThinUS$ 1500MOQ: 1 Ton