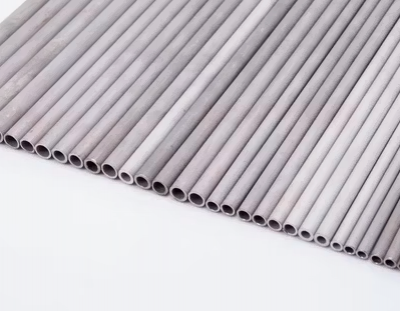

High Precision Galvanized Steel Heat Exchanger Tube ASTM B673 Uns N08925 Seamless and Welded Austenitic Stainless Steel

| Process Classification | Physical polishing (MP) |

| Pickling and polishing (AP) | |

| Bright annealing (BA) | |

| Electrolyte pickling (EP) |

Urea-grade stainless steel is austenitic stainless steel specially developed for high-temperature carbamate solutions (such as urea production). Urea grade stainless steel has strong corrosion resistance in high-temperature carbamate solution. The environment is generated when ammonium carbamate is used as a medium for the reaction of ammonia and carbon dioxide in urea production. It has strong resistance to local corrosion generated in the high-temperature carbamate environment of the high-pressure part of the urea equipment. 2522 stainless steel has little weight loss and local corrosion in the Huey test. 725LN is a fully austenitic structure and has a low content of non-metallic impurities. It is mainly used in the manufacture of urea production equipment.

In addition to focusing on cleanliness control in the production process, the focus is on the control of heat treatment links. They are all ultra-pure stainless steels, which mainly solve the problem of selective corrosion of ferrite in the ammonia environment during urea synthesis.

Super austenitic stainless steel pipe has higher cleanliness, uniformity, mechanical properties, finer structure, better surface quality, better resistance to local corrosion of harsh media, and better process manufacturing performance than ordinary austenitic stainless steel pipe.

This material is specially used in the urea industry. Therefore, urea and 316l stainless steel are called. Urea and stainless steel need to undergo Hugh test and selective corrosion test.

| Caliber Code | OD | SCH | |||||||||||||||||

| Nominal Diameter DN | Inch | Outer Diameter mm | SCH 5S | SCH 10S | SCH 40S | SCH 80S | SCH 10 | SCH 20 | SCH 30 | STD | SCH 40 | SCH 60 | XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | XXS |

| 6 | 1/8 | Φ10.29 | - | 1.24 | 1.73 | 2.41 | - | - | - | 1.73 | 1.73 | 2.41 | 2.41 | - | - | - | - | - | |

| 8 | 1/4 | Φ13.72 | - | 1.65 | 2.24 | 3.02 | - | - | - | 2.24 | 2.24 | - | 3.02 | 3.02 | - | - | - | - | - |

| 10 | 3/8 | Φ17.14 | - | 1.65 | 2.31 | 3.20 | - | - | - | 2.31 | 2.31 | - | 3.20 | 3.20 | - | - | - | - | - |

| 15 | 1/2 | Φ21.34 | 1.65 | 2.11 | 2.77 | 3.73 | - | - | - | 2.77 | 2.77 | - | 3.73 | 3.73 | - | - | - | 4.78 | 7.47 |

| 20 | 3/4 | Φ26.67 | 1.65 | 2.11 | 2.87 | 3.91 | - | - | - | 2.87 | 2.87 | - | 3.91 | 3.91 | - | - | - | 5.56 | 7.82 |

| 25 | 1 | Φ33.4 | 1.65 | 2.77 | 3.38 | 4.55 | - | - | - | 3.38 | 3.38 | - | 4.55 | 4.55 | - | - | - | 6.35 | 9.09 |

| 32 | 1.1/4 | Φ42.16 | 1.65 | 2.77 | 3.56 | 4.85 | - | - | - | 3.56 | 3.56 | - | 4.85 | 4.85 | - | - | - | 6.35 | 9.70 |

| 40 | 1.1/2 | Φ48.26 | 1.65 | 2.77 | 3.68 | 5.08 | - | - | - | 3.68 | 3.68 | - | 5.08 | 5.08 | - | - | - | 7.14 | 10.15 |

| 50 | 2 | Φ60.32 | 1.65 | 2.77 | 3.91 | 5.54 | - | - | - | 3.91 | 3.91 | - | 5.54 | 5.54 | - | - | - | 8.74 | 11.07 |

| 65 | 2.1/2 | Φ73.02 | 2.11 | 3.05 | 5.16 | 7.01 | - | - | - | 5.16 | 5.16 | - | 7.01 | 7.01 | - | - | - | 9.53 | 14.02 |

| 80 | 3 | Φ88.9 | 2.11 | 3.05 | 5.49 | 7.62 | - | - | - | 5.49 | 5.49 | - | 7.62 | 7.62 | - | - | - | 11.13 | 15.24 |

| 90 | 3.1/2 | Φ101.6 | 2.11 | 3.05 | 5.74 | 8.08 | - | - | - | 5.74 | 5.74 | - | 8.08 | 8.08 | - | - | - | - | - |

| 100 | 4 | Φ114.3 | 2.11 | 3.05 | 6.02 | 8.56 | - | - | - | 6.02 | 6.02 | - | 8.56 | 8.56 | - | 11.13 | - | 13.49 | 17.12 |

| 125 | 5 | Φ141.3 | 2.77 | 3.40 | 6.55 | 9.53 | - | - | - | 6.55 | 6.55 | - | 9.53 | 9.53 | - | 12.70 | - | 15.88 | 19.05 |

| 150 | 6 | Φ168.28 | 2.77 | 3.40 | 7.11 | 10.97 | - | - | - | 7.11 | 7.11 | - | 10.97 | 10.97 | - | 14.27 | - | 18.26 | 21.95 |

| 200 | 8 | Φ219.08 | 2.77 | 3.76 | 8.18 | 12.70 | - | 6.35 | 7.04 | 8.18 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 10 | Φ273.05 | 3.40 | 4.19 | 9.27 | 12.70 | - | 6.35 | 7.80 | 9.27 | 9.27 | 12.70 | 12.70 | 15.09 | 18.26 | 21.44 | 25.40 | 28.58 | 25.40 |

| Nominal Outer Diameter D(mm) | Nominal Thickness S(mm) | ||||||||||||||

| 0.51 | 0.71 | 0.89 | 1 | 1.15 | 1.24 | 1.65 | 2.11 | 2.41 | 2.77 | 3.05 | 3.18 | 3.4 | 3.96 | 4.78 | |

| Φ3.175 | × | × | × | ||||||||||||

| Φ6.35 | × | × | × | × | × | ||||||||||

| Φ9.53 | × | × | × | × | × | × | × | × | × | × | |||||

| Φ12.70 | × | × | × | × | × | × | × | × | × | × | |||||

| Φ14.30 | × | × | × | × | × | ||||||||||

| Φ15.88 | × | × | × | × | × | ||||||||||

| Φ19.05 | × | × | × | × | × | × | × | × | × | ||||||

| Φ25.40 | × | × | × | × | × | × | × | × | × | × | |||||

| Φ31.75 | × | × | × | × | × | × | × | × | × | × | |||||

It is used in industrial environments with harsher working conditions and stronger corrosion resistance, which ordinary austenitic stainless steel cannot meet, such as media environments such as butyl acetate, acetic acid, formic acid, terephthalic acid, polyvinyl chloride in the petrochemical industry; media environments such as sulfuric acid, ferric sulfate, soda ash, phosphoric acid in inorganic chemicals; crude oil desalting and vacuum distillation in crude oil refining; superheaters, reheaters, and final reheaters in supercritical boilers, etc.

| Machinable Materials | ||||

| EN | TP | UNS | STANDARD | |

| 1.4301 | TP304 | S30400 | EN 10217/7TC1&TC2 | |

| 1.4306 | TP304L | EN 10296-2 | ||

| 1.4307 | TP304L | S30403 | EN10357 | |

| 1.4311 | TP304LN | S30453 | DIN11850 | |

| 1.4404 | TP316 | S31600 | AD2000W2-W4-W10 | |

| 1.4404 | TP316L | S31603 | ASTM/ASME A/SA249 | |

| 1.4406 | TP316LN | S31653 | ASTM A269 | |

| 1.4432 | TP316L | ASTM A270 | ||

| 1.4435 | TP316L | ASTM A554 | ||

| 1.4436 | TP316 | ASTM A632 | ||

| 1.4438 | TP317L | S31703 | ASTM A778 | |

| 1.4439 | TP317LNM | S31726 | ASTM/ASME B/SB674 | |

| TP317 | S31700 | ASTM/ASME A/SA312 | ||

| 1.4449 | TP317 | ASTM/ASME A/SA688 | ||

| 1.455 | TP347 | S34700 | ASTM/ASME B/SB676 | |

| 1.4541 | TP321 | S32100 | ||

| 1.4571 | TP316TI | S31653 | ||

| 1.4828 | TP309 | |||

| 1.4833 | TP309S | S30908 | ||

| 1.4845 | TP310S | S31008 | ||

| 1.4878 | TP321H | S32109 | ||

| 1.4948 | TP304H | S30409 | ||

| 1.4835 | 253MA | S30815 | ||

| ALLOY840 | S33400 | |||

| Ferritic Steel | ||||

| EN | TP | UNS | STANDARD | |

| 1.4016 | TP430 | S43000 | ASTM/ASME A/SA268 | |

| 1.4509 | TP441 | ASTM/ASME A/SA249 | ||

| 1.4512 | TP409 | EN10357 | ||

| 1.4521 | TP444 | ASTM A/SA803 | ||

| TP439M | S43932 | EN 10296-2 | ||

| 1.451 | TP439M | ASTM A554 | ||

| 1.452 | TP430Ti | |||

| TP439 | S43035 | |||

| TP410S | S41008 | |||

| 2.4630 | GH3030 | |||

| Duplex Steel | ||||

| EN | TP | UNS | GRADE | STANDARD |

| 1.4362 | S32304 | DSS 2304 | EN 10217/7 TC1&TC2 | |

| 1.4162 | S32101 | DSS 2101 | ASTM/ASME/SA789 | |

| S32003 | DSS 2003 | EN10357 | ||

| 1.441 | S32750 | DSS 2507 | AD 2000 W2 | |

| 1.4501 | S32760 | EN 10296-2 | ||

| S82031 | ASTM A554 | |||

| 1.4462 | S31803 | DSS 2205 | ASTM/ASME A/SA790 | |

| 1.4462 | S32205 | DSS 2205 | ||

| 1.4481 | S31260 | |||

| 1.4424 | S31500 | |||

| 1.4466 | S31050 | |||

| SUPERAUSTENITIC STEEL | ||||

| EN | TP | UNS | GRADE | STANDARD |

| 1.4529 | N08926 | 1925HMO | EN10296-2 | |

| N08367 | ASTM/ASME/SA249 | |||

| 1.4562 | N08031 | ALLOY 31 | ASTM A269 | |

| 1.4539 | N08904 | 904L | ASTM A270 | |

| 1.4547 | S31254 | 254SMO | ASTM/ASME A/SA312 | |

| ASTM/ASME B/SB676 | ||||

| AD 2000 W2 | ||||

| ASTM A632 | ||||

| ASTM/ASME B/SB674 | ||||

| ASTM/ASME A/SA688 | ||||

| ASTM/ASME B/SB674 | ||||

| ASTM/ASME A/SA468 | ||||

| NICKEL ALLOYS | ||||

| EN | TP | UNS | GRADE | STANDARD |

| 2.4602 | N06022 | ALLOY 22 | ASTM/ASME B/SB515 | |

| 2.4605 | N06059 | ALLOY 59 | ASTM/ASME B/SB516 | |

| 2.466 | N08020 | ALLOY 20 | ASTM/ASME B/SB626 | |

| 2.4633 | N06025 | ALLOY 25 | ASTM/ASME B/SB704 | |

| 1.4563 | N08028 | ALLOY 28 | ASTM B/SB751 | |

| 1.4876 | N08800 | ALLOY 800 | ASTM/ASME B/SB730 | |

| 2.4858 | N08825 | ALLOY 825 | ASTM/ASME B/SB468 | |

| 2.436 | N04400 | ALLOY 400 | AD 2000 W2 | |

| 2.4816 | N06600 | ALLOY 600 | EN 10217/7 TC1&TC2 | |

| 2.4851 | N06601 | ALLOY 601 | ||

| 2.47 | N06058 | ALLOY 2120 | ||

| 2.4675 | N06200 | ALLOY C2000 | ||

| 2.4068 | N02201 | ALLOY 201 | ||

| 2.4733 | N06230 | ALLOY 230 | ||

| 2.4819 | N10276 | C-276 | ||

| 2.4856 | N06625 | ALLOY 625 | ||

| 1.4959 | N08811 | INCOLOY 800HT | ||

| 2.4060 | N02200 | NICKEL 200 | ||

| 2.4600 | N10675 | Hastelloy B-3 | ||

| 2.4617 | N10665 | Hastelloy B-2 | ||

Q1: Are you a trading company or manufacturer?

We are a processing type company specializing in processing stainless steel for 304/304L large diameter thick wall stainless steel welded pipe and other materials. Prompt delivery, low price, high quality, unique insight into various materials of stainless steel, rolled round, straight seam, ring seam.

Q2: What are the company's main products?

304/304L stainless steel welded pipe processing, Thick-walled stainless steel welded pipe processing, Large diameter stainless steel welded pipe processing, Customizable stainless steel shrimp elbow, etc.

Q3:What are the advantages of your company?

We have many professionals, technical personnel, more competitive prices, and better after-sales service than other stainless steel companies.

Q4: What do you do to control product quality?

Before loading into the container, all products will go through a pre-shipment inspection by our professional QC group. UT test is called is applied to steel material, according to Sep 1921 C/c, D/d, or E/e level based on different types of steel.

Q5:What is your MOQ?

Our MOQ for each order is around 25 Tons(one container), customers can mix different types of steel to reach this quantity.

Q6: Can we visit your company and factory?

Yes, warmly welcome! We can book the hotel for you before you come to China and arrange for our driver to our airport to pick you up when you come

Send Inquiry to This Supplier

You May Also Like

-

904L /1.4539/N08904 Austenitic Seamless Stainless Steel Pipe and Tube High-Temperature Usage ASTM A312/ASTM A213/ASTM A269US$ 300 - 500MOQ: 1 Ton

-

Astma312 /Astma213/Astma269 Tp904L/ 1.4539/ N08904 Seamless Stainless Steel PipeUS$ 35 - 50MOQ: 100 Kilograms

-

Factory Price 63mm 34mm Seamless Stainless Steel/Aluminum/Carbon Steel Pipe ASTM Carbon A53 0235 Galvanized Steel PipeUS$ 800 - 1100MOQ: 1 Ton

-

Round Pipe Tube Gi Steel Welded Steel Pre Galvanized Steel Schedule 40 60mm 2 Inch ERW Tubo De Acero De 2 Pugadas De Pared PipeUS$ 800 - 1100MOQ: 1 Ton

-

ASTM Round/Rectangular Ss 201 304/304L 316/316L 310S 309S 409 904 430 6061 Brushed/Mirror Polished Seamless/Welded Stainless Steel Tube Pipe PriceUS$ 800 - 1100MOQ: 1 Ton

-

ASTM A312 304/304L 316L 347H Pickling Stainless Steel Seamless Pipe Cold Drawn Seamless TubeUS$ 1200MOQ: 1 Ton

-

ASTM 201 304 304L 321 316 316L 317L 347H 309S 310S 904L Seamless/Galvanized/Carbon Steel/Stainless/Square/ERW/Rectangular Steel Tube PipeUS$ 800 - 1100MOQ: 1 Ton

-

Hot Sale/ASTM A106 A53/Seamless Steel Pipe Galvanized/Fluid Fire Boiler Tube PipeUS$ 800 - 1100MOQ: 1 Ton

-

Round A106 Gr. B API 5L Seamless Pipes for Pipeline TransportationUS$ 800 - 1100MOQ: 1 Ton

-

ASTM 316 1cr17ni12mo2 S31600 X5crnimo1810 1.4571 Stainless Steel Seamless Tube Pipe for Aircraft PartsUS$ 800 - 1500MOQ: 1 Ton