Industrial Pipe S22053 Duplex Stainless Steel Tube the Third Party Certification

Duplex stainless steel is a family of steel alloys that comprise chromium, nickel and molybdenum in their composition and they have a dual nature of steels. The austenitic and ferritic steel phases are present in the metallurgic microstructure of this family and as a Super Duplex Stainless Steel Pipe Manufacturer we produce all kinds of pipes in the super duplex range.

Lean duplex stainless steels: The lean duplex grades such as S32101, S32202, S82011 and S32304 are characterized by relatively low levels of nickel and/or molybdenum. To compensate for the reduced nickel content, which is a strong austenite former, these grades have increased levels of nitrogen and manganese, which provide an acceptable austenite/ferrite phase balance. As a group the lean grades have high strength, particularly yield strength, and exhibit a pitting and crevice corrosion resistance that is similar to, or just below that, of the Type 316L austenitic grade. Because of their relatively high yield strength, the lean DSSs are well suited for tank construction and structural applications.

Standard duplex stainless steels: The standard duplex grades typically contain 21-25% chromium, 2-3% molybdenum and 0.15% nitrogen. Grades in this category are used widely across all industry sectors and 2205 (S32205) has become by far the most widely used duplex grade. The 2205 grade has a yield strength that is more than twice that of Type 316 and a pitting and crevice corrosion resistance that is similar to Type 904L austenitic stainless steel. Applications for standard duplex grades include tanks, piping, process vessels and structural applications.

Super duplex stainless steels: The super duplex stainless steels typically contain 25% chromium, 3.5-4.0% molybdenum, and 0.25-0.27% nitrogen. The pitting and crevice corrosion resistance of the super duplex grades are essentially equivalent to the 6% Mo super austenitic stainless steels. The most widely used super duplex stainless steel grades are the 2507 (S32750) and Z100 (S32760) grades. Common applications include piping, heat exchangers, tanks, and process vessels used for chemical processing and marine applications.

Hyper duplex stainless steels: The hyper duplex stainless steels, S33207 and S32707 are the most highly alloyed of the duplex family and contain 26-30% chromium, 3.5-5.0% molybdenum, and 0.30-0.50% nitrogen. The hyper duplex grades are designed for more aggressive acid and chloride-containing environments. They are produced in limited quantities and are currently only available as seamless tubing.

| ISO Designation | EN | UNS | AISI | JIS | GB |

| X6CrNiCuSiMo19-10-3-2 | 1.4660 | SUS315J1 | |||

| X6CrNiSiCuMo19-13-3-3-1 | 1.4648 | SUS315J2 | |||

| X6CrNiMoCu18-12-2-2 | 1.4665 | SUS316J1 | |||

| X6CrNiMoTi17-12-2 | 1.4571 | S31635 | SUS316Ti | S31668 | |

| X3CrNiMo18-12-3 | 1.4449 | ||||

| X2CrNiMoCu18-14-2-2 | 1.4647 | SUS316J1L | S31683 | ||

| X2CrNiMo17-12-3 | 1.4432 | S31603 | SUS316L | S31603 | |

| X6CrNiMoNb17-12-2 | 1.4580 | S31640 | S31678 | ||

| X40CrNi1 5-14 | 1.4867 | SUH31 | |||

| X3CrNiCuMo17-11-3-2 | 1.4578 | ||||

| X3CrNiMoBN17-13-3 | 1.4910 | ||||

| X2CrNiMoN17-12-3 | 1.4429 | S31653 | "316LN" | SUS316LN | S31653 |

| X2CrNiMoN17-11-2 | 1.4406 | S31653 | "316LN" | SUS316LN | S31653 |

| X6CrNiMoN17-12-3 | 1.4495 | S31651 | 316N | SUS316N | S31658 |

| X2CrNiMo18-14-3 | 1.4435 | S31603 | 316L | SUS316L | S31603 |

| X2CrNiMo17-12-2 | 1.4404 | S31603 | 316L | SUS316L | S31603 |

| X6CrNiMoS17-12-3 | 1.4494 | S31620 | 316F | SUS316F | |

| X5CrNiMo17-12-2 | 1.4401 | S31600 | 316 | SUS316 | S31608 |

| X3CrNiMo17-12-3 | 1.4436 | S31600 | 316 | SUS316 | S31608 |

| X3CrNiMo18-16-5 | 1.4476 | SUS317J1 | S31794 | ||

| X2CrNiMo19-14-4 | 1.4438 | S31703 | SUS317L | S31703 | |

| X2CrNiMoN18-15-5 | 1.4483 | S31726 | S31723 | ||

| X30CrNiMoPB20-11-2 | 1.4879 | SUH38 | |||

| X2CrNiMoN17-13-5 | 1.4439 | S31726 | S31723 | ||

| X6CrNiMo19-13-4 | 1.4445 | S31700 | 317 | SUS317 | S31708 |

| X2CrNiMoN18-12-4 | 1.4434 | S31753 | "317LN" | SUS317LN | S31753 |

| X6CrNiTiB18-10 | 1.4941 | S32109 | S32169 | ||

| X7CrNiTi18-10 | 1.4940,1.4541 | S32109 | "321H" | SUS321H | S32169 |

| X6CrNiTi18-10 | 1.4541 | S32100 | 321 | SUS321 | S32168 |

| X1CrNiMoCuN24-22-8 | 1.4652 | S32654 | S32652 | ||

| X2CrNiMnMoN25-18-6-5 | 1.4565 | S34565 | S34553 | ||

| X8CrNiNb16-13 | 1.4961 | ||||

| X7CrNiNb18-10 | 1.4912 | S34709 | "347H" | SUS347H | |

| X6CrNiNb18-10 | 1.4550 | S34700 | 347 | SUS347 | S34778 |

| X6NiCrSiNCe35-25 | 1.4854 | S35315 | |||

| X3NiCr18-16 | 1.4389 | S38400 | 384 | SUS384 | S38408 |

| X6NiCrTiMoVB25-15-2 | 1.4980,1.4606 | S66286() | "660" | SUH660 | S51525 |

| X3CrNiMoN27-5-2 | 1.4460 | S31200 | S22553 | ||

| X2CrNiMoN25-7-3 | 1.4481 | S31260 | SUS329J4L | S22583 | |

| X2CrNiMoSiMnN19-5-3-2-2 | 1.4424 | S31500 | |||

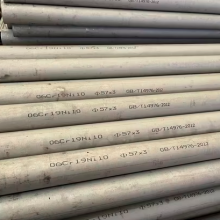

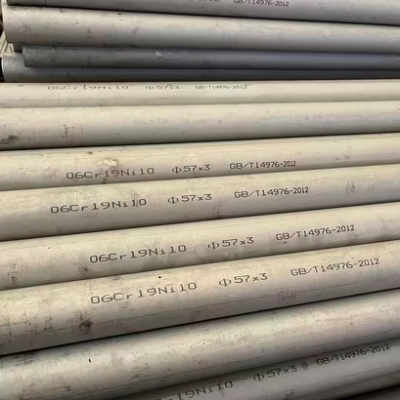

| X2CrNiMoN22-5-3 | 1.4462 | S32205,S3 | F51,F60 | SUS329J3L | S22053 |

| X2CrMnNiN21-5-1 | 1.4162 | S32101 | |||

| X2CrNiN22-2 | 1.4062 | S32202 | |||

| X2CrNiN23-4 | 1.4362 | S32304 | S23043 | ||

| X3CrNiMoCuN26-6-3-2 | 1.4507 | S32550 | S25554 | ||

| X2CrNiMoCuN25-6-3 | 1.4507 | S32520 | |||

| X2CrNiMoCuWN25-7-4 | 1.4501 | S32760 | S27603 | ||

| X2CrNiMoN25-7-4 | 1.4410 | S32750 | S25073 | ||

| X2CrNiMoCoN28-8-5-1 | 1.4658 | S32707 | |||

| X2CrNiMoN29-7-2 | 1.4477 | S32906 | |||

| X6CrNiMo26-4-2 | 1.4480 | S32900 | 329 | SUS329J1 | |

| X2CrNiMoN31-8-4 | 1.4485 | S33207 | |||

| X2CrMoTiS18-2 | 1.4523 | S18235 |

Call to Action (CTA)

📞 Contact Now for Best Price!

📧 Email: jane@zjzzgy.cn

💬 WhatsApp: +86 19005872308

Send Inquiry to This Supplier

You May Also Like

-

ASTM A789/ ASTM A790 Seamless Duplex Stainless Steel Tube-Heat Exchanger Tube Classification Society CertificationNegotiableMOQ: 1 Piece

-

SA789 Uns S31803 Duplex 2205 Stainless Steel Seamless Tube EU 3.2 CertificationUS$ 800 - 1100MOQ: 1 Ton

-

Customized A790 Grade Seamless/Welder CD6mn Duplex Stainless Steel Pipe TubeUS$ 800 - 1100MOQ: 1 Ton

-

Hot Rolled En 1.4462 Inox Tube Manufacturer Uns S31803/Uns S32205 Duplex/Super DuplexUS$ 800 - 1100MOQ: 1 Ton

-

ASTM Hot Rolled Stainless Steel Pipes Heat Exchanger Duplex Steel S31803 S32205 S32750 S32760 4inch Sch80s Full Size Seamless Square Steel PipeUS$ 800 - 1100MOQ: 1 Ton

-

Stainless Steel Alloy Duplex 2205 Uns S32205 Pipes Supplier in Large Stockist at Standard ASTM A789/A790US$ 800 - 1100MOQ: 1 Ton

-

Premium Super Duplex A780 Seamless Pipes for Industrial UseNegotiableMOQ: 1 Piece

-

ASTM A789 S32205 Duplex Stainless Steel Tubo De Acero Smls Pipe for Pressure Ship RepairUS$ 800 - 1100MOQ: 1 Ton

-

ASTM A789/ ASTM A790 Uns S32760 1.4501 X2crnimocuwn 25-7-4 25cr Seamless Duplex Stainless Steel Tube-Heat Exchanger TubeUS$ 800 - 1100MOQ: 1 Piece

-

S32205/S2507/S31803 A312 A790 GOST Duplex Stainless Steel Seamless PipeUS$ 800 - 1100MOQ: 1 Ton