BFS Leak Detection Automatic Visual Inspection Machine

Automatic Ampoule and Vial Inspection Machine

Ampoule Vial Inspection Machines

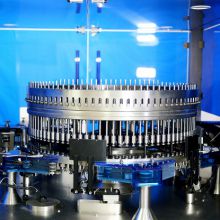

Automatic Ampoule and Vial Inspection Machine

WE are manufacturing inspection systems for the pharmaceutical industry. automatic inspection machines for injectable pharmaceutical products contained in syringes, ampoules, vials, cartridges and bottles, guarantees precise optical alignment between cameras, lights and containers for superior detection performance.

Product Description

It is mainly used to inspect visible impurities (such as glass, metal scraps, fiber, hair, white powder and flakes etc.) and liquid level of Ampoules from 1 to 20ml and 2ml to 100 Vials, 30 ml to 250ml bottle or more customized. It can also check whether there are ashy top, Carbide point, cusp, bubble head and micro pore on the Glass ampoule and Vials.

Inspecting procedure:

Products to be inspected→ feed in → photoelectric inspection zone → rotate Ampoule & Vials – glass → stop → take pictures → bottle divided device distinguishes qualified Ampoule & Vials – glass and the rejects according to software instructions → Qualified Ampoule & Vials – glass and the rejects feed out separately.

Main Structure:

1. Rack → Vial-in feed conveying devices → Vial-in feed wheel→ rotary tray→ Vial-pressing device → rotary apparatus → cam lift → quick change size parts device → out feed wheel → qualified products/rejects collection plate.

2. Driving system, servo system → computer software processing system → control system

3. inspection camera → lighting device → light harrier → Light source servo tracking device → image processing system

Working Principle

First, use mechanical visual principle to inspect visible impurities (such as glass, metal scraps, fiber, hair, white powder, flakes etc.) in ampoule liquid, and check ashy top, Carbide point, cusp, bubble head, micro pore and liquid level of ampoule and vial , The inspected products are transferred to impurity inspect station by wheel, and it finished ashy top, Carbide point, cusp and bubble head inspection in the transfer process. On the impurity inspection stations, the product is braked static while it rotates in high speed, industrial cameras take a series of photos continuously on it and computer system analyze and compare those photos to judge whether impurities exist in the inspect product and finish liquid level inspection at the same time. Then, those products are transferred to micro pore and crack inspection stations by wheel.

Apply high frequency high voltage to both ends of inspected products, and judge whether micro pore and cracks exist on Glass Ampoule and Vial s or not by comparing the micro electric current. After inspection, the qualified products and rejects will be separated automatically.

Technical parameters:

· Inspecting items: visible impurities (such as glass, metal scraps, fiber, hair, white powder, flakes etc.), ashy top, Carbide point, cusp, bubble head, micro pore and liquid level

Send Inquiry to This Supplier

You May Also Like

-

Automatic Visual Inspection MachineNegotiableMOQ: 1 Tray

-

Lyophilized Powders ,vial , Glass Ampoule Visual Inspection MachineNegotiableMOQ: 1 Set

-

Injections and Implanted Drug Products (Parenterals)—Product Quality TestsNegotiableMOQ: 1 Set

-

Tablet Capsule Automatic Visual Inspection MachineNegotiableMOQ: 1 Tray

-

AVI Ampoule Visual Inspection MachineNegotiableMOQ: 1 Tray

-

AVI Tablet Capsule Visual Inspection MachineNegotiableMOQ: 1 Tray

-

Lyophilized Powders ,vial , Glass Ampoule Leak Detection MachineNegotiableMOQ: 1 Tray

-

Lyophilized Powders ,vial , Glass Ampoule Cleaning MachineNegotiableMOQ: 1 Tray

-

Automatic Visual Inspection Machine for Liquid DrugsNegotiableMOQ: 1 Tray

-

BFS Automatic Visual Inspection MachineNegotiableMOQ: 1 Tray