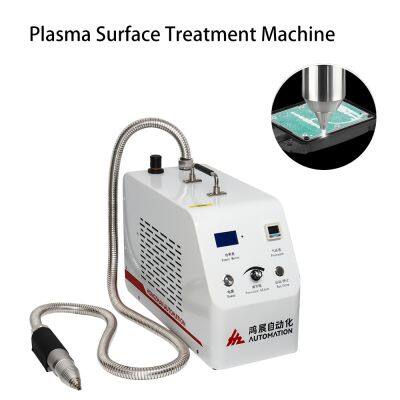

Plasma Surface Treatment Machine Direct Injection Low Temperature Plasma Machine Plasma Surface Treatment Machine for Injection Molded Parts

Plasma treatment is an efficient and environmentally friendly surface treatment technology, widely used in electronic manufacturing, metal processing, fiber treatment and other fields. Its core effects and characteristics are as follows: I. Surface treatment effect Surface activation and adhesion enhancement Through plasma bombardment of the material surface, organic pollutants and oxides are removed to form a microscopic rough structure, which significantly improves the surface energy and wettability, and enhances the bonding with adhesives, coatings or solders. The introduction of polar functional groups such as hydroxyl and carboxyl groups changes the chemical properties of the material and improves compatibility with polar substances. Surface Cleaning and Uniformity Effectively removes grease, dust and other contaminants, avoiding residues, suitable for processes with high cleanliness requirements. The treatment process is non-contact and uniform, suitable for complex structures or large surfaces, avoiding mechanical damage. Chemical modification and functional optimization By adjusting the type of gas (e.g. oxygen, nitrogen, argon) and treatment parameters, the surface hydrophilicity, electrical conductivity or optical properties can be directionally regulated. For example: ITO conductive film treatment to improve adhesion with optical adhesive, fiber treatment to enhance the uniformity of dyeing. Typical application effects Electronic manufacturing field SMT process: solder paste printing before treatment can reduce the virtual welding, empty welding, three-proof paint coating before treatment to improve the uniformity of the coating. Display / touch screen: enhance the bonding strength of ITO glass and optical adhesive, reduce display defects. Metal processing field Significantly improve the adhesion of metal surface coating, improve anti-corrosion performance, reduce process costs. Fiber and polymer materials Enhanced capillary effect and wettability after fiber surface treatment, improved dyeing rate and printing clarity. Third, the effect of continuity and factors affecting The effect of plasma treatment gradually decay over time, the active groups can usually be maintained for about 48 hours, depending on the environment (such as air contact), the length of treatment, power and gas type. It is recommended to proceed to the next process (e.g. coating, bonding) as soon as possible after treatment to ensure the best results. IV. Technical Advantages Environmentally friendly: no chemical solvents, reducing pollution. High efficiency: short treatment time (seconds to minutes), after drying can be directly into the subsequent process.

Send Inquiry to This Supplier

You May Also Like

-

CNC Machining Parts With Chrome Plating Surface TreatmentUS$ 0.01 - 10.09MOQ: 90 Pieces

-

ShuoBao Supply Water Filtration Machine for Surface TreatmentUS$ 100 - 1,000MOQ: 2 Pieces

-

Aluminum Precision CNC Machined Part, Nickel Surface TreatmentUS$ 0.01 - 100MOQ: 100 Pieces

-

Best Selling Ion Magic Wand Plasma Device Skin Rejuvenation Machine Freckle Treatment Machine Salon Beauty EquipmentUS$ 40 - 50MOQ: 1 Piece

-

Multi-functional Brushing Machine for Stone Crystal Floor Used/Stone Crystal Surface Treatment MachineNegotiableMOQ: 1 Piece

-

Plasma Surface Treatment MachineUS$ 4000 - 10000MOQ: 1 Set

-

Plasma Surface Treatment Machine SupplyNegotiableMOQ: 1 Piece

-

Plasma Surface Treatment Machine Direct Injection Low Temperature Plasma Machine Plasma Surface Treatment Machine for Injection Molded PartsNegotiableMOQ: 1 Unit

-

Plasma Surface Treatment MachineNegotiableMOQ: 1 Set

-

Atmospheric Plasma Surface Treatment MachineUS$ 1 - 10,000MOQ: 1 Set