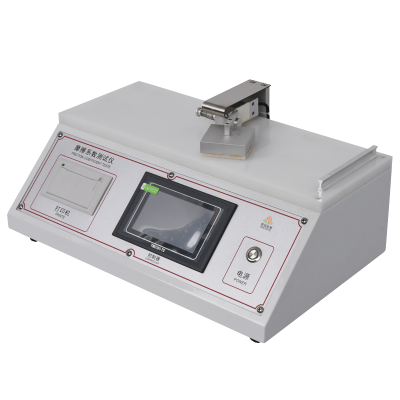

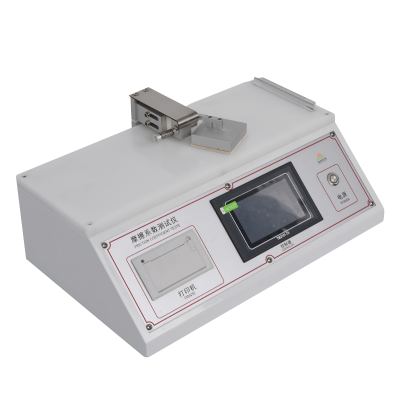

Dynamic coefficient of friction tester Technical parameters

Test range | 0.01~10N, accuracy: 0.01N |

Thickness of the specimen | ≤0.2mm |

Slider size | 63*63mm |

Slider mass | 200±2g |

Test stable size | 170*225mm |

Slider velocity | 100±10mm/mim |

Slider stroke | 0~150mm(adjustable) |

Force range | 0~5N |

Size | 500*335*220mm |

Power supply | AC 220 50Hz |

Weight | 22kg |

Friction Coefficient Tester_Friction Coefficient Tester_Friction Coefficient Tester_Friction Coefficient Measuring Instrument Features

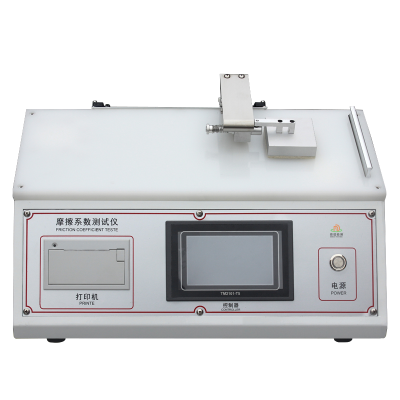

1、System can simultaneously determine the static friction coefficient and dynamic friction coefficient of the specimen, and the resting time is automatically timed.

2、The coefficient of friction of static and dynamic is automatically cleared at the beginning of the experiment, which ensures the full contact between the specimens and improves the accuracy of the test results.

3, the instrument test bench and test slider are demagnetized and residual magnetism detection, effectively reducing the system test error.

4, the equipment adopts microcomputer control, with menu-type operation interface, PVC control panel and LCD screen, which is convenient for users to carry out test operations and data viewing.

5、LCD screen real-time display curve, force value and dynamic and static friction coefficient.

6、Equipped with micro printer.

7、Support 200g and 500g slider mass conversion.

8、Support 70mm and 150mm test stroke conversion.

9、Equipped with mechanical and electronic double protection, limit the protection of the accuracy of the sensor.

10, equipped with R232 serial port function, convenient for users to export experimental data. (Optional)

Friction coefficient meter_Friction coefficient tester_Friction coefficient tester_Friction coefficient tester_Friction coefficient measuring instrument Product Application

Professional applicable to measure the static friction coefficient and dynamic friction coefficient of paper, cardboard, plastic film, sheet, rubber, YL with tube , woven bag, fabric style, communication cable fiber optic cable with metal material composite belt, conveyor belt, wood, coating, brake pads, windshield wipers, shoe materials, tires and other materials when sliding. By measuring the slipperiness of the material, it can control the adjustment of the material production quality process indicators to meet the requirements of product use. In addition, it can also be used for the determination of the smoothness performance of cosmetics, eye drops and other daily chemical products.

Plastic Film Friction Coefficient Tester is a special instrument for testing the friction coefficient of plastic film surface. When using this instrument, the following are some important precautions:

Preparation:

Before use, make sure the instrument has been calibrated and is in good working condition.

Check whether all parts of the instrument are intact and undamaged.

Operating Environment:

Conduct the test in a stable temperature and humidity environment to avoid the influence of environmental factors on the test results.

Ensure that the test environment is clean to avoid dust and impurities affecting the test results.

Sample Preparation:

Samples should be flat, wrinkle-free and free of contamination.

Make sure the size of the sample meets the test requirements.

Operation Procedure:

Carefully read and follow the steps in the operation manual.

Avoid applying excessive pressure to the sample during the test to avoid affecting the accuracy of the test results.

Safety matters:

When operating the instrument, do not wear gloves or anything that could be caught in the instrument.

Keep hands and other objects away from moving parts during instrument operation.

Data Recording:

Record test data accurately, including test conditions, test results, etc.

If necessary, conduct multiple tests to obtain the average value and improve the reliability of the data.

Maintenance:

Maintain and calibrate the instrument regularly.

After use, clean the instrument in time to keep it clean and dry.

Abnormal handling:

If abnormalities are encountered during the test, stop the test immediately and check the cause.

Do not try to operate the instrument forcibly before troubleshooting.

The following are specific precautions:

Calibration and standardization: The instrument should be calibrated periodically using standard samples to ensure the accuracy of the test results.

Operator: The instrument should be operated by trained personnel to ensure proper use.

Sample Placement: During testing, samples should be placed correctly on the test platform to avoid errors caused by improper placement.

Test speed: Keep the speed stable during the test to avoid speed fluctuation affecting the test results.

Data Handling: Handle test data correctly to avoid calculation errors.

Following these precautions can help ensure the safety of using the Plastic Film Friction Tester and the accuracy of the test results.

Send Inquiry to This Supplier

You May Also Like

-

TAPPI T815 Paper Friction Tester - Static & Kinetic COFUS$ 1300 - 2300MOQ: 1 Set

-

Dual-Specimen Friction Tester - Simultaneous Static & Dynamic TestingUS$ 1300 - 2300MOQ: 1 Set

-

Dynamic Coefficient of Friction Tester (DCOF)US$ 1300 - 2300MOQ: 1 Set

-

Multi-function Coefficient of Friction TesterUS$ 1300 - 2300MOQ: 1 Set

-

Coefficient of Friction Test Equipment for Laboratory UseUS$ 1300 - 2300MOQ: 1 Set

-

Salt Spray Test Chamber Manufacturer - CE Certified Salt Spray Testing MachineUS$ 950 - 2250MOQ: 1 Set

-

500L Capacity Salt Spray Testing Machine - ASTM B117 ComplianceUS$ 1050 - 2250MOQ: 1 Set

-

Salt Spray Test Machine Supplier - Professional Manufacturer in China, Global Shipping AvailableUS$ 1050 - 2250MOQ: 1 Set

-

Salt Spray Testing Equipment Price - Factory Outlet Free Technical SupportUS$ 1050 - 2250MOQ: 1 Set

-

Salt Spray Testing Standards - AASS, CASS, NSS Testing Methods ExplainedUS$ 1050 - 2250MOQ: 1 Set