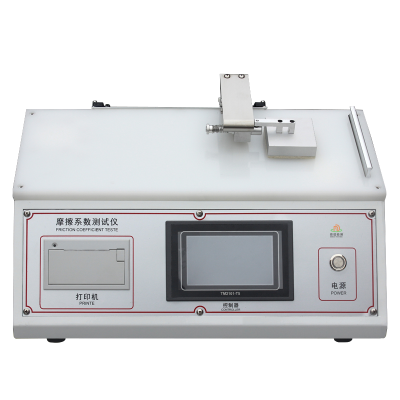

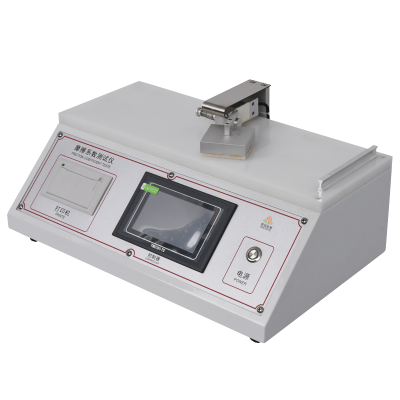

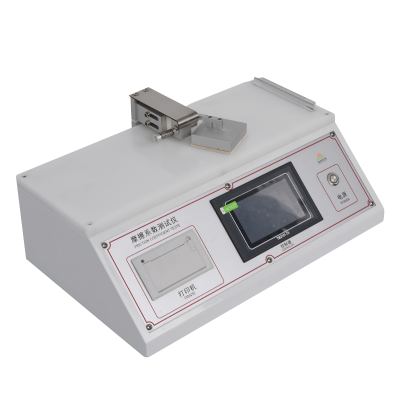

Dynamic coefficient of friction tester Technical parameters

Test range | 0.01~10N, accuracy: 0.01N |

Thickness of the specimen | ≤0.2mm |

Slider size | 63*63mm |

Slider mass | 200±2g |

Test stable size | 170*225mm |

Slider velocity | 100±10mm/mim |

Slider stroke | 0~150mm(adjustable) |

Force range | 0~5N |

Size | 500*335*220mm |

Power supply | AC 220 50Hz |

Weight | 22kg |

I. Functional Features

Multiple test modes: support static coefficient of friction, dynamic coefficient of friction, wear performance and other test modes to meet the testing needs of different materials and application scenarios.

High-precision sensor: adopts high-precision load sensor and displacement sensor to ensure the accuracy and repeatability of measurement data.

Intelligent control system: Equipped with advanced intelligent control system, it can realize automatic loading, automatic measurement, automatic calculation of friction coefficient and other functions to improve the testing efficiency and precision.

Customizable slider: according to the customer's demand, the slider can be customized with different materials, sizes and qualities to adapt to various testing standards and material characteristics.

Stepless speed regulation: The test speed is stepless adjustable within the range of 10-500mm/min, which can simulate the friction under different speeds.

Data Recording and Analysis: Built-in data storage function can record the detailed data of each test and provide data analysis tools to facilitate data processing and report generation.

Safety protection device: with overload protection, emergency stop, automatic return and other safety functions to ensure the safety of operators and equipment.

Second, the application areas

Material R&D: Help researchers evaluate the friction performance of new materials and optimize the material formulation and preparation process.

Quality control: to test the coefficient of friction of raw materials or finished products in the production line to ensure that product quality meets standards.

Mechanical engineering: to assess the lubrication effect and wear resistance of mechanical components, and improve the service life and reliability of equipment.

Packaging industry: to test the sliding performance of packaging materials to ensure the smoothness of the packaging process and the stability of packaging quality.

Automotive industry: to assess the coefficient of friction of automotive interior materials, brake pads, tires, etc., to ensure driving safety and material durability.

Electronics industry: testing the friction performance of electronic equipment shells, buttons, screens, etc., to improve the service life of products and user experience.

Textile industry: Measure the friction coefficient of fabrics, leather, etc. to optimize the touch and wear resistance of products.

Third, the use of conditions

Ambient temperature: the device can work normally under the environment of -10°C to 50°C, but under the condition of 23±2°C can get the best measurement accuracy.

Relative humidity: Adapt to 5% to 95% humidity range, but should avoid prolonged use in high humidity environment, so as not to affect the life and performance of electronic components.

Power Requirements: Stable AC220V/50Hz power supply is required, and a voltage regulator is recommended to prevent voltage fluctuations from damaging the equipment.

Installation environment: It should be installed on a flat, solid workbench, avoiding vibration, direct sunlight and strong electromagnetic interference to ensure the stability and accuracy of the testing process.

Services and Support

Pre-sales consulting: professional team to provide detailed technical advice to help customers determine the test requirements and equipment selection.

Installation and commissioning: provide on-site installation and commissioning services to ensure the normal operation of the equipment.

Operation Training: Provide equipment operation and maintenance training to customer operators to ensure the correct use of equipment.

After-sales service: Provide regular maintenance and quick repair services to ensure the long-term stable operation of the equipment.

Send Inquiry to This Supplier

You May Also Like

-

Paper & Board Friction Tester - TAPPI T815 Static & Dynamic COFUS$ 1300 - 2300MOQ: 1 Set

-

Rubber Friction Coefficient Tester - ISO 4649 Skid Resistance TestingUS$ 1300 - 2300MOQ: 1 Set

-

TAPPI T815 Paper Friction Tester - Static & Kinetic COFUS$ 1300 - 2300MOQ: 1 Set

-

Dual-Specimen Friction Tester - Simultaneous Static & Dynamic TestingUS$ 1300 - 2300MOQ: 1 Set

-

Dynamic Coefficient of Friction Tester (DCOF)US$ 1300 - 2300MOQ: 1 Set

-

Salt Spray Test Chamber Manufacturer - CE Certified Salt Spray Testing MachineUS$ 950 - 2250MOQ: 1 Set

-

500L Capacity Salt Spray Testing Machine - ASTM B117 ComplianceUS$ 1050 - 2250MOQ: 1 Set

-

Salt Spray Test Machine Supplier - Professional Manufacturer in China, Global Shipping AvailableUS$ 1050 - 2250MOQ: 1 Set

-

Salt Spray Testing Equipment Price - Factory Outlet Free Technical SupportUS$ 1050 - 2250MOQ: 1 Set

-

Salt Spray Testing Standards - AASS, CASS, NSS Testing Methods ExplainedUS$ 1050 - 2250MOQ: 1 Set