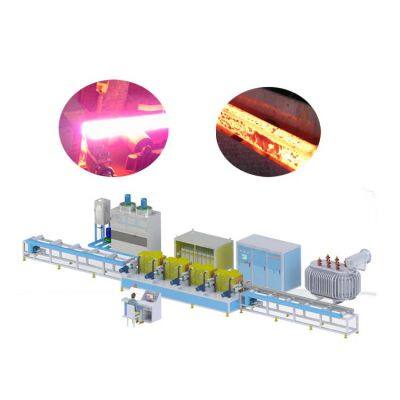

FOREVER Steel Billet Induction Reheating Production Line

14 years of professional production and sales of steel billet continuous casting and rolling heating furnace. Familiar with the continous casting billet design and process, Forever can not only supply best quality steel billet continuous casting and rolling heating furnace but also we will help you to choose the best solution

1) Billet needs to be increased by 300℃, from 750℃ to 1050 ℃.

2)Capacity: 180T/H, billet specification: 150x150x12000mm, 180x180x12000mm

3) Working model: Continuous, inline

4)Working mode: Achieve automatic increasing billet temperature as per pyrometer set before the induction heating unit.

5)Workpiece temperature distribution: The temperature distribution characters for continuous casing billet section, the core temperature is 1050°C or more; the surface temperature is 750°C, and the surface temperature need to increase by 300℃.

6)Billet maximum bending requirements: Maximum bending is 5mm per meter, head ≤ 40mm, body:<50mm

The speed of the billet at the medium speed transmission area must meet the safety distance of 12 meters from the medium speed to the slow speed in order to make sure that the speed of the billet before charging the inductor has reduced to the slow uniform transmission state.

7)Temperature accuracy:±10℃

Main technical parameters of steel billet hot rolling heating furnace:

● Applicable workpieces: Suitable for pre rolling heating of steel billets, square billets, square steel, continuous casting billets, slabs, etc.

● Power supply system: Dual rectifier 12 pulse or 24 pulse 1000-12000KW/500-1200Hz, single power supply can be used independently or multiple power supplies can be used in parallel; The hourly output is 40-300 tons.

● Applicable range: 120mm~160mm square billet, length 3000mm~12000mm.

● Feeding system: Each axis is driven by an independent motor reducer, with multiple axis drives set up and controlled by a single frequency converter to synchronize the operation of multiple axes.

● Guidance system: using 304 non-magnetic stainless steel guide wheels, and maintaining moderate elasticity in the axial direction of the guide wheels to adapt to the allowable bending range of the steel billet.

● Temperature closed-loop system: A closed-loop control system composed of Leitai infrared thermometer and Siemens S7, which automatically adjusts the power supply according to the initial temperature and feed rate of the steel billet entering the sensor, so as to maintain a constant heating temperature before it is discharged from the furnace.

● Energy conversion: Depending on the surface temperature of the steel billet, the power consumption per ton of steel is 40-60 degrees

Advantages and characteristics of steel billet hot rolling heating furnace:

●If a steel billet hot rolling induction heating furnace is used in the steel billet hot processing workshop, the workshop temperature is greatly reduced due to less heat loss, which improves the working conditions in the workshop. Due to the fact that the induction heating process for hot-rolled steel billets does not produce smoke or dust during the processing of workpieces, it purifies the working environment of the workshop and meets the requirements of energy conservation and environmental protection in the new era.

●In terms of electric heating for production equipment, resistance furnaces are rarely used for heating raw materials before hot forming because the heating temperature of the raw materials is relatively high and limited by electric heating elements. Therefore, induction heating is mainly used. Induction heating of raw materials before hot forming has been used in processes such as forging, hot stamping, hot extrusion, and hot cutting of raw materials.

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3m-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Send Inquiry to This Supplier

You May Also Like

-

FOREVER Continuous Casing Steel Billet Reheating ProcessUS$ 3000 - 200000MOQ: 1 Set

-

FOREVER Billet Induction Reheating FurnaceUS$ 3000 - 200000MOQ: 1 Set

-

FOREVER Billet Induction Reheating EquipmentUS$ 3000 - 200000MOQ: 1 Set

-

FOREVER Billet Induction Reheating Process Factory SupplierUS$ 3000 - 200000MOQ: 1 Set

-

FOREVER Electric Billet Induction Reheating Oven SupplierUS$ 3000 - 200000MOQ: 1 Set

-

Medium Frequency Induction Reheating Equipment for Steel BilletsUS$ 3000 - 200000MOQ: 1 Set

-

Induction Billets Medium Frequency Reheating EquipmentUS$ 3000 - 200000MOQ: 1 Set

-

Hot Rolling Steel Billet Induction Heating FurnaceUS$ 3000 - 200000MOQ: 1 Set

-

Steel Billet Induction Hot Rolling Heating EquipmentUS$ 3000 - 200000MOQ: 1 Set

-

Steel Billet Induction Heating Equipment for Hot Rolling FurnaceUS$ 3000 - 200000MOQ: 1 Set