Home > Products > Steel Billet Induction Heater > FOREVER Continuous Casing Steel Billet Reheating Process

FOREVER Continuous Casing Steel Billet Reheating Process

- tian jin

- T/T L/C

- 40 days

You May Like

-

Stainless Steel Pipe Induction Annealing Furnace

-

Stainless Steel Pipe Induction Annealing System Supplier

-

Steel Pipe Induction Annealing Production Line Factory

-

Induction Annealing Process for Steel Pipes

-

Induction Steel Pipe Annealing Machine for Long Steel Pipe

-

FOREVER Long Pipe Induction Annealing Furnace

Product Description

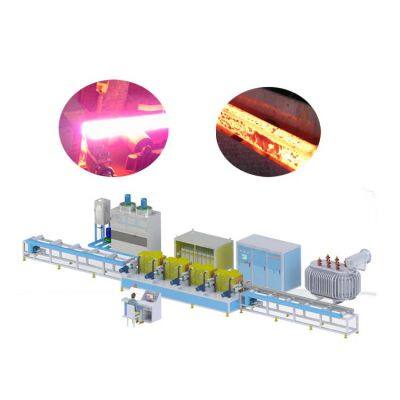

Continuous casting billet reheating production line is designed and manufactured by Forever Furnace including medium frequency,induction heater, automatic feeding system ,fast discharging system,infrared thermometer and PLC center console.Forever Furnace has exported many sets of continuous casting billet reheating system to Taiwan and the production line is running very well in the local factory.

Continuous Casting Billet Reheating Line Local Application

The Technical Solutions for Continuous Casting Billet Reheating Line:

1.Reheating the continuous casting billet to 1100℃;

2.Uniform temperature performance:uniform temperature performance of continuous casting billet is better than natural status before heating after the billet going through the induction reheating furnace.

3.Medium frequency power supply:

(1)Raising the temperature from 800℃ to 1100℃ within one minute as per the technical requirement.The required heating power is 5700KW.

(2)Electricity consumption in theory is 38 degree per ton of billet(For example,the electricity consumption is 25 degree per ton if you need to raise 200℃.

(3)In order to ensure the reliability of the heating furnace continuous running,we separate 5700KW power supply into two sets,5700KW for each set.

(4)Technical parameters for medium frequency power supply:

| No. | Item | Parameters |

| 1 | Master Power | 5700KW |

| 2 | Single Power | 5700KW |

| 3 | Incoming Line Voltage | 1000 KW |

| 4 | Rectifier Pulse | 12Pulse |

| 5 | IF Voltage | 1600V |

| 6 | IF Frequency | 1200HZ |

| 7 | Inductor Voltage | 3200V |

4.Induction heating furnace:

(1)Four segments of induction heating furnace equipped with one IF power supply.

(2)Billet size is 150mmX150mm,inductor size is 280mmX280mm,and the refractory material thickness is 20mm.The clearance between billet and refractory material is 45mm.

Provide Spare Parts List Free of Charge for continuous casting billet reheating line :

(1) Main control panel:Three sets.

(2)Inverter panel:Three sets.

(3)SCR:Nine sets.

(4)Refractory material:One bag

As an experience and professional manufacturer of induction heating system,Forever Furnace will provide the excellent heat treatment equipment with very competitive price.Or if you are facing any problem of induction heating field,we are also glad to help you as per our 20 years of experience.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Contact Us

- Hebei YuanTuo Electromechanical Equipment Mnufacturing Co.Ltd.

- Contact nameTom Chat Now

Product Categories

New Products

-

China Factory Supplies Steel Pipe Annealing Machine

-

Hot Sale Long Steel Pipe Induction Annealing Production Line

-

High Quality Steel Pipe Annealing Induction Heating Line

-

New Style Steel Pipe Annealing Induction Heating Equipment Factory

-

Steel Bar Hot Rolling for Steel Ball Forming Induction Furnace

-

Steel Ball Hot Rolling Production Line Supplier

-

Heating Furnace for Steel Ball Hot Rolling Production Line

-

Steel Ball Skew Rolling Mill

-

Steel Ball Skew Rolling Production Line

-

Grinding Steel Ball Production Equipment

-

Grinding Steel Ball Production Line

-

Skew Rolling Steel Ball Induction Forging Equipment

-

Grinding Ball Rolling Production Line Manufacturer

-

Steel Ball Making Production Line

-

Steel Long Bar Induction Heating Forging Machine

-

Long Bar Induction Forging Heating Equipment

-

Bar Induction Forging Heating Process

-

Bar Induction Forging Steel Bar Induction Heating Machine Supplier

-

Steel Bar Induction Forging Heating System Manufacturer

-

Induction Steel Sheet & Slab Heat Treatment Furnace

-

Plate Induction Hardening and Tempering Heat Treatment Equipment

-

Induction Plate Heat Treatment Furnace China Forever

-

High Efficiency Induction Plate Heat Treatment Furnace

-

High Efficiency Steel Plate / Sheet Heat Treatment Machine

Popular Searches

- feeder machine

- automatic feeder

- fish feeder

- fashion buckle

- metal buckle

- metal belt buckle

- zinc alloy belt buckle

- plastic buckle

- metal pin buckle

- remote control robot

- robot arm

- palletizing

- side release buckle

- commutator

- luggage strap belt

- purse hook

- toilet partition

- metal d ring

- d ring buckle

- square buckle

- agv robot chassi

- industrial robot

- winding machine

- auto feeder

- luggage belt

- fish farm feeder

- automatic fish feeder

- gold buckle

- round ring buckle

- bag buckle

Recommended Products

- Brick Making Machinery Block Making Machine Clay Brick Making Machine for Southeast Asia

- Bricks Machine Maker Red Brick Making Machine Hollow Block Making Machine for Concrete Brick

- Brick Making Machinery Concrete Block Machine Paving Brick Machine for Sale

- Factory Wholesale Cement Fully Fly Ash Indian Hydraulic Interlocking Automatic Concrete Brick Making Machine

- Brick Making Machinery Clay Brick Making Machine Concrete Block Making Machine Hollow Block Making Machine for Sale

- Manual Movable Concrete Block Machine Mobile Cement Brick Maker Machine Brick Making Machinery Block Making Machine

- Best Selling in Africa and Southeast Asia Automatic Brick Machine Easy to Install Brick Making Machinery Block Forming Machinery

- Small Mobile Auto Brick Making Machine Concrete Brick Laying Machine Cement Block Make Machine Brick Moulding Machine

- Low Investment Small Standard Immobile Moulding Ligthweigtged Bricks Machine Interlocking Brick Molder

- Paving Bricks Brick Making Machine Popular in India Can Produce Solid Bricks Block Making Machine

- Mobile Block Making Machine Small Mobile Hollow Brick Machine

- China Manufacturer Multi-Head CNC Gemstone Faceting & Polishing Machine With Servo Motors

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Processing Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Tom

Hi there! Welcome to my shop. Let me know if you have any questions.

Tom

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile