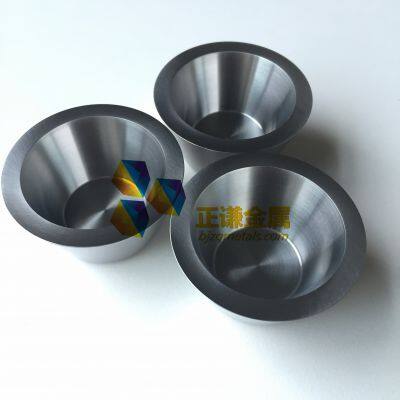

Polishing Bright Surface Molybdenum Crucible Molybdenum Cup Molybdenum Cylinder for Melting

2. Powder compaction: Use a hydraulic press or other compaction methods to compact the molybdenum powder to form a cylindrical green body.

3. Sintering: The green body is then sintered in a high-temperature furnace under a controlled atmosphere to bond the molybdenum particles together and achieve the required density and strength.

4. Mechanical processing: After sintering, the molybdenum cylinder can be mechanically processed such as turning, milling or grinding to obtain the final size and surface finish.

5. Quality Control: Finished molybdenum cylinders undergo quality control measures to ensure they meet specifications for purity, density, size and mechanical properties.

6. Surface treatment (optional): Depending on the application, molybdenum cylinders can receive surface treatments such as polishing, coating, or heat treatment to enhance their performance and durability.

2. Aerospace and Defense: Molybdenum cylinders are used in aerospace and defense applications, such as the construction of rocket engines, aircraft components, and missile systems, where high strength and heat resistance are critical.

3. Glass melting industry: Molybdenum cylinders are used in the glass industry to produce glass melting electrodes and other components used in the glass manufacturing process.

4. Semiconductor Manufacturing: Molybdenum cylinders are used in the semiconductor industry for applications such as ion implantation, sputtering targets, and other high-temperature processes.

5. Medical equipment: Molybdenum cylinders are used in the manufacturing of medical equipment, especially X-ray tube components and other medical equipment that require high temperature resistance and radiation resistance.

6. High-performance motorsports: Molybdenum cylinders are used in high-performance racing applications such as the construction of engine components and exhaust systems due to their high temperature resistance and lightweight properties.

Our factory

Baoji Zhengqian Nonferrous Metals Co. Ltd is located in the nonferrous metal processing base—Baoji City, Shaanxi Province, China. Our company is a comprehensive enterprise, and we have integrated the processing production and developing sales of the refractory metal and non-ferrous metal materials.

Advanced production technology and modern production equipment have been applied to professionally manufacture tungsten, molybdenum, tantalum, titanium, nickel and their alloyed materials and exquisite-manufactured parts , such as sheet, bar, pipe, foil, wire, target and crucible in various specifications. Our productions are widely used in many fields, for instance, aircraft industry, petrochemical industry, metallurgy, rare earth, coating, instrumentation, LED, electronic equipment, solar PV and medical equipment.

We have been insisted on “quality first, reputation first and faith first” for our business philosophy. And we have been providing better and better productions and service for our customers with all our hearts to get win-win cooperation and seek bilateral development.

Contact

Send Inquiry to This Supplier

You May Also Like

-

High Quality 99.95% Pure Molybdenum Bar Price Polished Surface Mo Bar/rod/stickUS$ 65 - 95MOQ: 1 Kilogram

-

99.95% Molybdenum Sintered Bar Moly Rod for SteelmakingUS$ 65 - 95MOQ: 1 Kilogram

-

High Hardness 99.95% 10.2g/cm3 High Temperature Resistant Low Expansion Rate Industrial Grade Pure Molybdenum Rod/rodUS$ 65 - 95MOQ: 1 Kilogram

-

99.95% Purity Molybdenum Rod Polished Moly BarUS$ 65 - 95MOQ: 1 Kilogram

-

2025 High Quality 99.95% Pure Polished High Purity Molybdenum Rod Mo Bar Molybdenum Bar Best PriceUS$ 65 - 95MOQ: 1 Kilogram

-

99.95% Pure Ground Molybdenum Rods, Moly Bar for Vacuum FurnaceUS$ 65 - 95MOQ: 1 Kilogram

-

Factory Price Molybdenum Bolt/screws Hot Selling Molybdenum Nuts in All SizesUS$ 95 - 100MOQ: 1 Kilogram

-

Customized M3 M4 M5 M6 Molybdenum Bolts/screws in Different SizesUS$ 95 - 100MOQ: 5 Kilograms

-

Stock Pure Molybdenum Metal Foil Molybdenum Strip for Melting SteelUS$ 100 - 120MOQ: 1 Kilogram

-

High Purity High Density 99.95% Pure Mo1 Crucibles Molybdenum CrucibleUS$ 65 - 105MOQ: 1 Kilogram