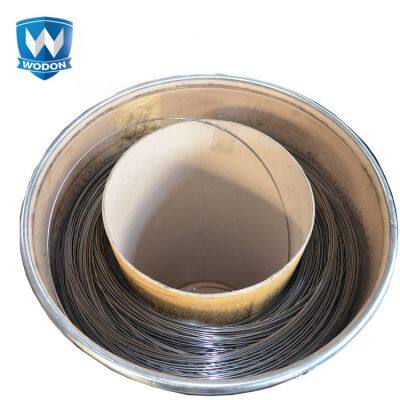

Wodon Factory Hardfacing Tungsten Welding Wire

1. A whole wire with no joint within one drum;

2. Uniform wire diameter, smooth wire feeding;

3. Stable arc, less spatter and smoke, no broken arc phenomena during welding;

4. Hardfacing efficiency over 90%;

5. Metallurgical bonding to base metal, uniform stress relief of after weld metal.

Flux cored welding wire We develop our wear resistant flux cored welding wires always according to working condition. This guarantee good performanceregarding no cleaning slag, low welding spatter, smooth surface, high welding efficiency. The Filling rate of flux cored welding wire are about 50% with tolerance 1%, so that the chemical composition after welding are uniform and stable. We use advanced CNC system and regular test during the production, so guarantee the good welding result. Wodon hardfacing welding wire with super wear resistance 1. Type: flux cored welding wire for hardfacing/surface welding/cladding 2. Diameter: 1.2 mm, 1.6 mm, 4.0 mm, customized. 3. Standard: GB 4. Certification: ISO9001:2008, ISO14001:2004, OHSAA 18001-2007 | ||||||||

Model | Diameter [mm] | Hardness [HRC] | Main Ingredient [%] | Main application and characteristics | ||||

D688 | 1,2;1,6 | 50-58 | C: 2.5-5.0 Cr: 22.5-27.5 | Apply to a serious part of grinding wear surfacing, multi-layer welding. Surfacing layer thickness can be up 50 mm | ||||

D788 | 1,2;1,6 | 50-60 | C: 3.0-4.5 Cr: 24-30 | Apply to a serious part of grinding wear surfacing welding, welding layer thickness control under 20 mm | ||||

D888 | 1,2;1,6 | 58-65 | C: 3.5-4.5 Cr: 24-27.5 | Apply to a serious parts of abrasive wear surfacing welding, welding layer thickness control under 10 mm | ||||

D788A | 1,2;1,6 | 50-60 | C: 3.0-4.5 Cr: 20-25 | Apply to a serious parts of abrasive wear surfacing, limited to single layer welding. | ||||

D788M | 1,2;1,6 | 60-66 | C: 3.0-4.5 Cr: 24-30 | Apply to a serious parts of abrasive wear surfacing | ||||

D688 Welding Rod | 4.0 | 50-58 | C: 2.5-5.0 Cr: 22.5-27.5 | Suitable for severe abrasive wear parts hardfacing welding, surfacing layer thickness control under 20 mm | ||||

Gas Shelding Welding Wire | ||||||||

Application | Model | Diameter (mm) | Hardness (HRC) | Main Ingredient | ||||

High manganese steel hardfacing wire, Suitable for hardfacing hammer head, hammer plate and other high impact parts | D114 | 1.6 | 50-55 | C, Cr, Mn | ||||

Suitable for hardfacing bucket gear, mining machinery and other wear parts | D172 | 1.2, 1.6 | ≥40 | C, Cr, Mo | ||||

Suitable for hardfacing the surface of wear parts, such as gear, digger. mining machinery and etc. | D212 | 1.2, 1.6 | ≥45 | C, Cr, Mo | ||||

Suitable for hardfacing high manganese rail, bulldozer and other wear parts under impact. | D256 | 1.6 | HB≥170 | C, Mn | ||||

Suitable for hardfacing continuous casting roll | D313 | 1.6 | 45-50 | C, Cr | ||||

Suitable for repairing die and toughening tool, and mechanical parts with high wear performance | D322 | 1.6 | 55-63 | C, W, Mo | ||||

Suitable for hardfacing hot rolling roll | D405 | 1.6 | 53-60 | C, Cr, Mo, W, V | ||||

Suitable for hardfacing general corrosion resistant parts | D430 | 1.6 | 35-40 | C, Cr | ||||

Suitable for hardfacing valve | D502Mo | 1.6 | 35-45 | C, Cr, Mo | ||||

Suitable for hardfacing continuous casting roll | D518 | 1.6 | 40-50 | C, Cr, Mo, Ni | ||||

Suitable for hardfacing heavy wear parts, multi-layer welding up to 50 mm | D688 | 1.2, 1.6 | 50-58 | C, Cr | ||||

Suitable for hardfacing heavy wear parts, multi-layer welding up to 20 mm | D788 | 1.2, 1.6 | 50-60 | C, Cr | ||||

Suitable for hardfacing heavy wear part, single layer welding only | D788A | 1.2, 1.6 | 50-60 | C, Cr | ||||

Suitable for hardfacing heavy wear parts, multi-layer welding up to 10 mm | D888 | 1.2, 1.6 | 58-65 | C, Cr | ||||

Suitable for hardfacing heat resistant wear parts | D995 | 1.6 | 58-65 | C, Cr, Nb, W, V | ||||

Cement Squeeze Roller Welding Wire | ||||||||

Application | Model | Diameter (mm) | Hardness (HRC) | Main Ingredient | ||||

Suitable for base layer | HB-JYG1# | 2.8 | - | C, Cr, Mo | ||||

Suitable for buffer layer | HB-JYG2# | 2.8 | 55-63 | C, Cr, Mo | ||||

Suitable for pattern layer | HB-JYG3# | 2.8 | 55-63 | C, Cr, Mo | ||||

Flux cored welding wire | ||||||||

Model | Spec. (mm) | Hardness (HRC) | Main Ingredient (%) | |||||

HB-YD172 | 1.2, 1.6 | ≥50 | C: 0.4-0.5 Cr: 1.5-2.5 Mo: 1.5-2.5 | |||||

Main Application:Used for surfacing welding gear, mining machinery, such as wear and tear parts. | ||||||||

Flux cored welding wire | ||||||||

Model | Spec. (mm) | Hardness (HRC) | Main Ingredient (%) | |||||

HB-YD313 | 1.6 | 45-50 | C: 0.2-0.3 Cr: 11-14 | |||||

Main Application:Used for continuous casting roller surfacing. | ||||||||

Flux cored welding wire | ||||||||

Model | Spec. (mm) | Hardness (HB) | Main Ingredient (%) | |||||

HB-YD256 | 1.6 | ≥170 | C: 0.5-1.1 Mn: 10-17 | |||||

Main Application:Used for all kinds crusher, high manganese steel rail, bulldozers and other easy wear welding parts. | ||||||||

Wodon hammerhead and hammer plate hardfacing welding wire with wear and impact resistance | ||||||||

Model | Spece. (mm) | Hardness (HRC) | Main Ingredient (%) | Application and characteristics | ||||

WD-D114 | 1.6 | 50~55 | C: 0.45~1 Cr: 2~3 Mn: 14~18 | High manganese steel surfacing welding wire, after violent shocks has the surface the characteristics of the strain hardening, suitable for welding such as impact hammerhead, hammer plate parts | ||||

Our company develop our own WD-series welding wire, which is self gas shielding welding wire. When you use our welding wire don't need shutz gas. After using of our WD-D114 high manganese surfacing welding wire to surfacing impact hammerhead and hammer plate have very good Impact resistance because of High chemical composite from flux core. | ||||||||

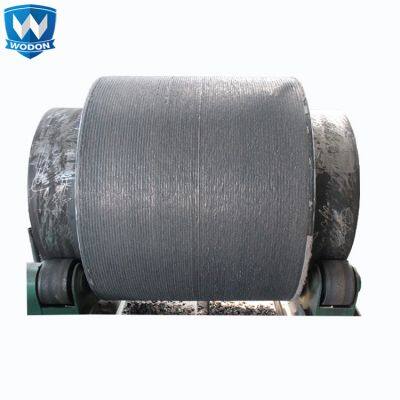

Wodon high standard wear resistant flux cored mig welding wire for hardfacing roller | ||||||||

Mig welding wire We develop our wear resistant flux core welding wires always according to working condition. This guarantee good performance regarding no cleaning slag, low welding spatter, smooth surface, high welding efficiency. | ||||||||

Model | Spec. (mm) | Hardness (HRC) | Main Ingredient | Application and Characteristics | ||||

WD-D430 | 2.4, 3.2 | 35~40 | C: 0.1~0.25 Cr: 16~18 | Used for general corrosion-resistant components surface welding | ||||

WD-D320H | 3.2, 4.0 | --- | C: 0.1~0.25 Cr: 12~14 | Suitable for continuous casting roll surface welding | ||||

WD-224 | 3.2, 4.0 | 45~55 | C: 0.25~0.35 Cr: 5.5~7.5 Mo: 0.8~1.5 W: 1.0~2.0 V: 0.5~1.0 | Suitable for hot-rolled billet roller surface welding | ||||

WD-224B | 3.2, 4.0 | 53~60 | C: 0.25~0.55 Cr: 5.5~7.5 Mo: 0.8~1.5 W: 1.0~2.0 V: 0.5~1.0 | Suitable for hot-rolled billet roller surface welding | ||||

WD-414N | 3.2, 4.0 | 40~50 | C: 0.05~0.15 Cr: 11.5~14.5 Mo: 0.5~1.5 | Suitable for continuous casting roll suface welding | ||||

WD-414-0 | 3.2, 4.0 | 40~50 | C: 0.05~0.15 Cr: 11.5~14.5 Mo: 0.5~1.5 | Suitable for continuous casting roll surface welding | ||||

WODON manufactured wear resistant hardfacing wire for vertical mill | ||||||||

Vertical Mill use wear resistant welding wire to repair | ||||||||

Model | Spec. (mm) | Hardness (HRC) | Main Ingredient | Application and Characteristics | ||||

WD100 | 2.4, 2.8, 3.2 | 55~62 | C: 3.0~5.0 Cr: 25~30 Mo: 0.5~1.0 | Used for repairing grinding coal mill roller of thermal power plant. | ||||

WD100A | 2.4, 2.8, 3.2 | 57~62 | C: 3.0~5.0 Cr: 27~32 Mo: 0.5~1.0 | Used for repairing cement roller mill of raw material, clinker and slag. | ||||

WD350 | 2.4, 2.8, 3.2 | 55~62 | C: 3.0~5.0 Cr: 22~28 Mo: 0.3~1.0 Nb: 3.0~4.5 | Used for repairing cement roller mill of raw material, clinker and slag. | ||||

WD350A | 2.4, 2.8, 3.2 | 57~62 | C: 3.0~5.0 Cr: 22~28 Mo: 0.3~1.0 Nb: 3.0~4.5 | Used for repairing cement roller mill of raw material, clinker and slag. | ||||

WD650 | 2.4, 2.8, 3.2 | 55~63 | C: 3.0~5.0 Cr: 22~28 Mo: 0.3~1.0 Nb: 6.0~7.5 | Used for repairing cement roller mill of raw material, clinker and slag. | ||||

WD650A | 2.4, 2.8, 3.2 | 57~63 | C: 3.0~5.0 Cr: 20~26 Mo: 0.3~1.0 Nb: 6.0~7.5 | Used for repairing cement roller mill of raw material, clinker and slag. | ||||

Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

General Description: Characteristics: 1. A whole wire with no joint within one drum; 2. Uniform wire diameter, smooth wire feeding; 3. Stable arc, less spatter and smoke, no broken arc phenomena during welding; 4. Hardfacing efficiency over 90%; 5. Metallurgical bonding to base metal, uniform stress relief of after weld metal. | ||||||||

Wodon flux cored gas shielding surface welding gear welding wire We developed our own flux cored welding wire with customized ingredient for all kinds of working conditions. Our welding wires has following advantages:1. smooth wire feeding, stable arc , uniform diameter 2. less patter and smoke during welding, above 90% hardfacing efficiency 3. every drum packed with one whole PC of welding wires, without any joint, no broken arc phenomena during the welding to improve production efficiency 4. developing more than 100 kinds of flux cored wear resistant requirements of many wear resistant field which can satify the wear resistant requirements of many wear resistant parts under all kinds of working conditions. 5. the base metal and the wear resistant overlay are metallurgical bonding; after welding, the wear resistant layer doesn't fall off because of uniform stress relief. We can provide qualification certificate, product data sheet, test report including chemical compostion, hardness, etc of wear resistant overlay. | ||||||||

Model | Spec. (mm) | Hardness (HRC) | Main Ingredient (%) | Application and Characteristics | ||||

WD-ZYG100 (1#) | 1.6, 2.8, 4.0 | -- | C: 0.03~0.15 Mn: 0.5~2.5 | Used in squeeze roller backing welding | ||||

WD-ZYG100 (1996) | 1.6, 2.8, 4.0 | -- | C: 0.05~0.15 Cr: 18~22 Ni: 8~11 Mn: 4~7 | Used in squeeze roller backing welding | ||||

WD-ZYG200 | 1.6, 2.8, 4.0 | 20~35 | C: 3.5~4.6 Cr: 4.0~6.0 Mo: 0.3~1.0 Nb: 0.3~1.0 | Used for welding transition layer of extrusion roller | ||||

WD-ZYG300 | 1.6, 2.8, 4.0 | 50~55 | C: 0.3~1 Cr: 5~10 Mo: 0.5~1.5 Nb: 1~3 | Used for welding transition layer of extrusion roller | ||||

WD-ZYG500 | 1.6 | 55~60 | C: 0.5~2.5 Cr: 5~10 Mo: 0.5~1.5 Nb: 3~6 | Used in welding extrusion roller surface and pattern layer | ||||

Wodon manufactured Tungsten carbide flux cored welding wire for die and tough | ||||||||

Our company developed special tungsten carbide flux cored welding wires are with super good wear resistance and good impact resistance, which are suitable for wear parts with heavy wear like die and tough. After welding garantee a hardness 55-63 HRC or 600-780 HV, no need for shutz gas,no cleaning slag, low welding spatter, smooth surface, high welding efficiency. | ||||||||

Model | Diameter [mm] | Carbon [%] | Tungsten [%] | Molybdenum [%] | ||||

D322 | 1.6 | 0.3-0.5 | 7-10 | 0.5-2.5 | ||||

Hardness [HRC] | 55~63 | 55~63 | ||||||

Application | Suitable for repairing die and tough, and require a higher wear properties of mechanical parts. | Suitable for repairing die and tough, and require a higher wear properties of mechanical parts. | ||||||

Wodon wear resistant flux cored welding wire for hardfacing steel factory hot roller | ||||||||

1. Type: flux cored welding wire for hardfacing. 2. Diameter: 1.6 mm, 3.2 mm, 4.0 mm, customized. 3. Standard: GB 4. Certification: ISO9001:2008, ISO14001:2004, OHSAA 18001-2007 | ||||||||

Model | Diameter [mm] | Hardness [HRC] | Main Ingredient [%] | Application | ||||

WD224 | 3.2;4.0 | 45-55 | C: 0.25-0.35 Cr: 5.5-7.5 Mo: 0.8-1.5 W: 1.0-2.0 V: 0.5-1.0 | Suitable for hot rolling roller surfacing welding, after welding have good wear, impact and heat resistance. | ||||

WD224B | 3.2;4.0 | 53-60 | C: 0.25-0.35 Cr: 5.5-7.5 Mo: 0.8-1.5 W: 1.0-2.0 V: 0.5-1.0 | Suitable for hot rolling roller surfacing welding, after welding have good wear, impact and heat resistance. | ||||

WD405 | 1.6 | 58-65 | C: 0.25-0.35 Cr: 5.5-7.5 Mo: 0.8-1.5 W: 1.0-2.0 V: 0.5-1.0 | Suitable for hot rolling roller surfacing welding, after welding have good wear, impact and heat resistance. | ||||

1,Portable Spectrum

2, Rockwell Hardness tester

3,Welding wire experiment table

4,Factory

5,Workshop

6,Warehouse

1. screen plate/vibrating plate

2. proetection cover

3. bolt embedded in the back

4. round to square transition

5. bend

6. trough

Welding wire for hardfacing coal scraper conveyor | ||||||||

Central groove after using high hardness flux core wire | ||||||||

Model | Spec. (mm) | Hardness (HRC) | Main Ingredient | Application and Characteristics | ||||

ZBS-100 (D212) | 1.2, 1.6 | ≥50 | C: 0.4~0.7 Cr: 4.0~5.5 Mo: 0.8~1.5 | Used for surface welding, the surfaces of all wear parts, such as gears, bucket, mining, machinery etc. | ||||

ZBS-200 (D688) | 1.2, 1.6 | 45~55 | C: 2.5~5.0 Cr: 22.5~27.5 | Apply to a serious part of abrasive wear surface multi-layer welding. Surfacing layer thickness can be up to 50 mm. | ||||

ZBS-300 (D888) | 1.2, 1.6 | 58~65 | C: 3.5~4.5 Cr: 24~27.5 | Apply to a serious part of abrasive wear surface welding, welding layer thickness control under 10 mm. | ||||

provides study opportunites, continuously improves welfare and work environment. To the pursuit of perfect quality and customer satisfaction, we have certified with ISO9001 quality management system, ISO14001 environmental management system, OHSAS18001 occupational health and safety management system. We sincerely provide high quality wear resistant products and services to customers. We will always supply our best products, adhere to quality first and keep up the spirit of striving for perfection.We use our own developed CNC automatic welding machine with multi welding guns to weld our own hardface wear plate. These can overcome the problems like: low productivity, poor flatness and overlay falling off etc. This is a high automation level machine, each welding gun can operate independently and restart exactly from the point it had stopped, simplifying the operation process.

in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company’s technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.4 Major production bases: Jiangsu, Hebei, Hunan, Jiangsu. 68 Wear plate production lines (over 130 welding torches). 5 Welding wire production lines.Annual output of chromium carbide wear plates: 200,000 square meters

Annual output of flux cored hardfacing wires: 9000 tons.

A:We are based in Jiangsu, China, start from 2014,sell to Domestic Market,Oceania,North America,South

Q:how can we guarantee quality?

Q:what can you buy from us?

A:Chromium Carbide Overlay Plate,Wear Plate Liner,Flux Cored Welding Wire

Q:why should you buy from us not from other suppliers?

A:The chromium content as high as 25~50% in the overlay The chromium carbide (Cr7C3) volume fraction above 50% Uniform distribution and high hardness HRC 58~65 Smooth surface, thickness tolerance +0~+0.5 mm only Flatness tolerance -3~+3 mm/m

Accepted Payment Currency:USD,AUD,CNY;

Accepted Payment Type: T/T,L/C,Cash;

Language Spoken:English,Chinese,Spanish,Portuguese,German

Send Inquiry to This Supplier

You May Also Like

-

Overlay Hardfacing Flux Cored Welding Wire for Cement Squeeze Roller & Steel Mill Roller Metal & Metal Products RepairingCAD 300 - 300MOQ: 1 Kilogram

-

China Plant Submerged Open Flux Cored Arc Welding Wire for Hardfacing Repairing Coal Mill RollerCAD 300 - 300MOQ: 1 Kilogram

-

HB-YD788 High C Cr Wear Resistant Plate Hardfacing CCO Flux Cored Welding Wire for Medium to High Impact-OEM CustomizableUS$ 5 - 5MOQ: 1 Kilogram

-

High Hardness Wear-Resistant Plate for Coal Mining Mill Roller Repair Flux Cored Welding Wire Hardfacing Metal & Metal ProductsCHF 2.5 - 2.5MOQ: 1 Kilogram

-

High CCO Flux Cored Welding Wire for Wear Plate Hardfacing & Gas Shielded Welding Metal & Metal ProductsUS$ 5 - 5MOQ: 1 Kilogram

-

Overlay Hardfacing Flux Cored Repairing Welding Wire Mig Carbide Chrome Cement Squeeze Roller and Steel Mill RollerCAD 300 - 300MOQ: 1 Kilogram

-

Wodon Ferro Chromium Flux Cored Welding Wire With Repairing Wear PartsUS$ 3.56 - 3.56MOQ: 1 Kilogram

-

Wodon High-Carbon Chromium Hardfacing Flux Cored Welding Wire Premium Metals & Metal ProductsUS$ 3.24 - 3.24MOQ: 1 Kilogram

-

Wodon Wear Resistant Flux Cored Welding Wires for Wear Plate and RepairingCHF 9 - 9MOQ: 1 Square Meter

-

Wodon Gas Shielding Wear Resistance CO2 Mig Flux Cored Welding WireCHF 9 - 9MOQ: 1 Square Meter