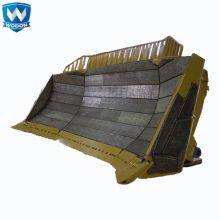

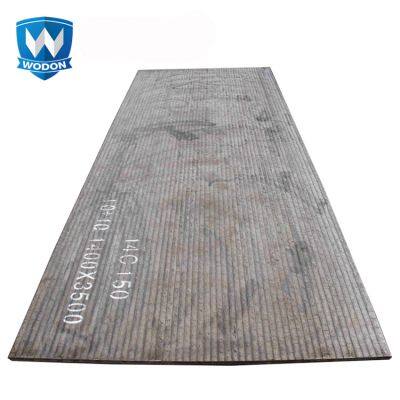

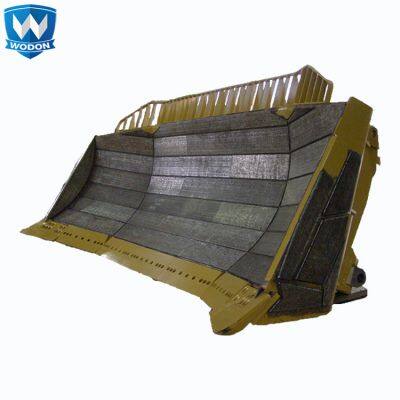

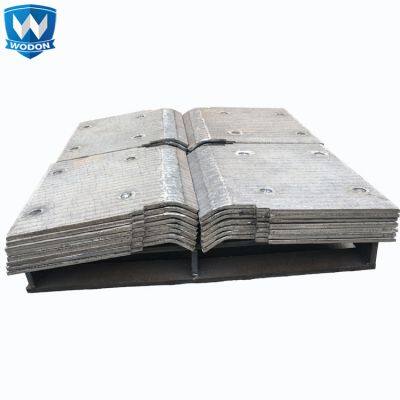

Wodon High Hardness Steel Sheet Mining Bulldozer Liner Plate Hardfacing Wear API Standard Cutting Bending Welding Processing

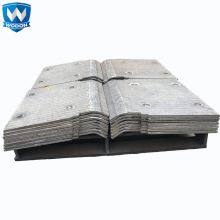

Wodon wear plates are manufactured by welding one or multiple wear resistant layers on a medium or low carbon steel base plate.

The overlay alloy has a high amount of chromium carbide hard particles which makes the plate have good wear and impact resistance.

Overlay thickness range: 3-50mm

Wear plate size(mm): 1400*3000, 1400*3400, 1400*3500,

1500*3000,2000*3000, 2100*3500,

others on request

|

|

Jiangsu Wodon Wear Resistant Material Co., Ltd. (China Wodon) is a manufacturing factory specializing in the development

and production of wear resistant materials. We are headquartered in Jiangsu, a port hub city in North China. There are over

300 staffs, including 30 experienced R&D engineers. Our main products include: Chromium carbide overlay (CCO) wear plates,

Flux cored hardfacing welding wires etc.

With independent intellectual property rights and a number of patents, we have a strong R&D and debugging team,

which can provide customers with a streamlined service.

Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the

lead in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which

win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the

wear resistant industry as the company’s technical consultant to ensure strong technical strength and production capacity,

we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.

4 Major production bases: Jiangsu, Hebei, Hunan, Jiangsu

68 Wear plate production lines (over 130 welding torches)

5 Welding wire production lines

Annual output of chromium carbide wear plates: 200,000 square meters

Annual output of flux cored hardfacing wires: 9000 tons.

Test Equipment

OUR CUSTOMERS

Why choose us?

1. The overlay chemical composition is the key

The main ingredients of Wodon plates are C(%) :3.0-5.0 and Cr(%):25-40. This chemical proportion results in a large amount of

Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee

a super wear resistant surface.

Performance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions: Choosing same dimension specimens for different materials and wear plate producers, and put them under the

same wearing working conditions in our testing equipment.

2. Chromium carbide microstructure

The wear resistance of wear plate depends mostly on the hardness, shape, size, amount and distribution of the chromium

carbide hard particles.

3. Bonding strength between the overlay and base plate.

The overlay and base plate are very well bonding. The overlay will penetrate into base plate about 0.8mm-1.8mm, reaching

up to 350Mpa in our tests.

Send Inquiry to This Supplier

You May Also Like

-

10+10 Thickness Wear-Resistant Clad Plates for Mining Excavators Bucket Wheel Excavator With Bosch Rexroth Hydraulic CylinderCHF 500 - 500MOQ: 1 Piece

-

Wodon Super Wear-Resistant Steel Plate With Chromium Carbide Overlay Sheet or Coil Type for Cutting Processing ServicesCHF 300 - 300MOQ: 1 Square Meter

-

Chrome Carbide Wear Resisting Plate High Wear Steel Plate Wear Liner Platebimetallic Wearable Lining Plate Bucket ExcavatorCHF 300 - 300MOQ: 1 Square Meter

-

WODON High Wear Resistance Truck Inner Liner PlateUS$ 150 - 150MOQ: 1 Square Meter

-

Chromium Carbide Overlay Wear Resistant Truck Bed Liners Dump Haul Steel Sheet ANSI Standard Cutting Bending Welding ProcessingCHF 399 - 399MOQ: 1 Set

-

Wodon Factory CCO Wear Plate,wear Plate (WD1200) Manufactured in ChinaUS$ 500 - 500MOQ: 1 Piece

-

Bimetallic Hardfacing Cladding Abrasion Resistant Wearable Lining Plate Bucket Excavator LinerUS$ 120 - 120MOQ: 1 Square Meter

-

High Chrome High Carbide Coated Steel Sheet Plate Wear Resistant With Cutting Welding Bending Processing ServicesCHF 300 - 300MOQ: 1 Square Meter

-

Wodon High Chrome High Carbide Coated Wear Resistant Steel Sheet Plate Certified Cutting/Welding/BendingCHF 300 - 300MOQ: 1 Square Meter

-

Bimetallic Hardfacing Cladding Wearable Lining Plate Bucket for Wheel Excavator Abrasion ResistantUS$ 300 - 300MOQ: 1 Square Meter