Wodon Bimetallic Chromium Carbide Wear-resistant Steel Plates

Wodon chromium carbide hardened steel plate with super wear resistance

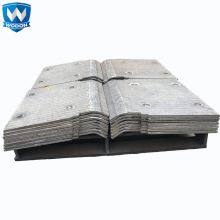

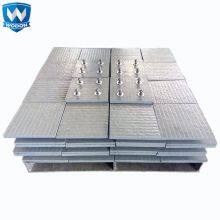

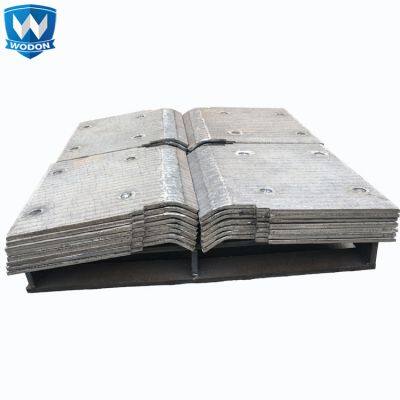

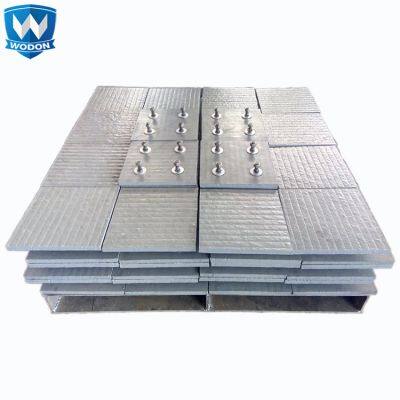

1. Wear resistant steel plate:

Medium/low carbon steel+abrasion resistant layers→wear resistant steel plate with metallurgical bonding

(Q235/Q345B+Chromium Carbide overlay→wear resistant composite plate with Submerged arc or Open arc welding)

2. Process:

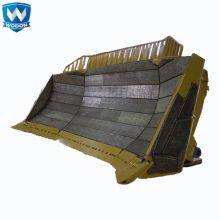

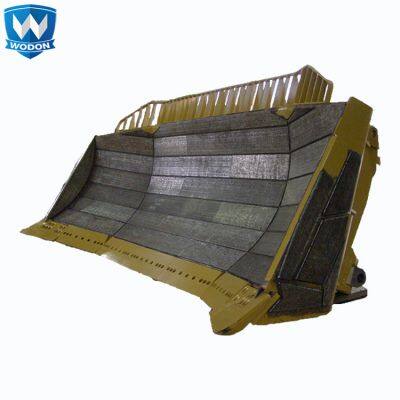

All kinds of Liner are made of wear resistant steel plate by cutting, bending, punching, bolting and welding.

According to customer's drawings.

3. Standard size: max. 2400*4000 mm without split joint, Customer's Requirement

Open arc welding plate : 1.4 m*3.4 m, customized

Submerged arc welding plate : 1.4 m*3.0 m, 1.4 m*3.5 m, 2.1 m*3.5 m, customized4. Certification: ISO 9001: 2008

5. Detail:

The overlay alloy has a high amount of chromium carbide hard particles. These particles are distributed evenly throughout the layer, creating a strong microstructure. The hardness is HRC 55~65 and depends on the overlay's thickness.

Six Classifications of Wodon Wear plate | ||||

No. | Grade | Feature and Property | ||

1 | General wear plate | C: 3.0~4.5% Cr: 15~27% | ||

2 | High Chromium wear plate | C: 3.5~5.5% Cr: 27~40%, wear resistant overlay thickness maximum up to 25 mm | ||

3 | Impact resistant wear plate | Independent R&D, with high wear and high impact resistance | ||

4 | Heat resistant wear plate | Independent R&D, with heat resistance maximum up to 900 °C | ||

5 | No crack wear plate | Hardness: 50~52 HRC, mainly used in housing liner of steel mill, domestic unique product | ||

6 | Special chemical elements wear plate | Customized, chemical elements: Mo, Nb, Ni, W, V etc | ||

Other Feature and Property | ||||

Chemical composition: Wodon wear plates are manufactured by welding one or multiple abrasion resistant layers on a medium or low carbon steel base plate. The overlay alloy has a high amount of chromium carbide hard particles. Micrrostructure: The chromium carbide volume fraction on the microstructure is above 50%. Hardness: Chromium carbide hard particles are distributed evenly throughout the layer, creating a strong microstructure. The hardness is between HRC 58~65 and depends on the overlay's thickness. Wear resistance: Our test shows that the wear resistance of Wodon plate is 20 times higher than low carbon steel and 8 times than heat treated steel. Flatness tolerance: Flatness tolerance is ±3 mm/m. Thickness tolerance: Uniform overlay thickness, with tolerance within 0~0.5 mm. | ||||

The main thickness | ||||

3 on 3, 4 on 4, 5 on 5 4 on 6, 5 on 6, 6 on 6, 8 on 6, 4 on 8, 5 on 8, 6 on 8, 7 on 8, 8 on 8, 4 on 10, 5 on 10, 6 on 10, 7 on 10, 8 on 10, 9 on 10, 10 on 10, 20 on 10, 4 on 12, 5 on 12, 6 on 12, 7 on 12, 8 on 12, 10 on 12, 12 on 12, 18 on 12, 20 on 12, 6 on 14, 8 on 14, 10 on 14, 6 on 16, 8 on 16, 10 on 16, 6 on 18, 8 on 18, 10 on 18, 5 on 20, 6 on 20, 8 on 20, 10 on 20, 10 on 30, 10 on 40, 20 on 20, 25 on 20, We can customize the plates in different sizes and thicknesses based on customer's drawings. We can also cut, bend and weld the wear plates into specific shapes and parts. | ||||

Jiangsu Wodon Wear Resistant Material Co., Ltd is a company which is specialized in researching and developing wear resistant material. The company was founded in 2014. Now we have more than 200 employees, including more than 50 R&D staffs. Our company's registered capital is 5 million USD with an annual output of 9000 tons welding wires and 90000 square meters wear plate.

With numerous experienced technicians and excellent engineers, our product quality has improved constantly. Since company established, we are adhering to professional development road and win the market with the leading technological level, the excellent product quality and the integrative service concepts. We keep a long-term cooperation with Beijing University of technology, Iron and Steel Research Institute, Beijing Electric Power Equipment Research Institute etc.

Jiangsu Wodon main products: wear plates, wear plate welding wires, coal grinding roller welding wires, vertical cement mill welding wires, squeeze roller welding wires, roller welding wires etc. We have independent intellectual property right, multiple patents, professional team for researching and debugging, providing one-stop services for customers.

Jiangsu Wodon products are widely used in many industries, for example: power, iron and steel, cement, glass, mining, coal processing, metallurgical machinery, engineering machinery, loading machinery, port transportation etc. Wear resistant plate is far ahead of other similar products on the market in many ways, such as chemical composition, microstructure, hardness, wear resistance performance, flatness etc. Our wear plate can greatly extend maintenance time, thereby reducing maintenance cost in the practical application.

Why our wear plate has such good wear resistance?

1. The overlay chemical composition is the key

The main ingredients of Wodon plates are C: 3.0~5.0% and Cr: 25~40%. This chemical proportion results in a large amount of prime chromium carbide (Cr7C3) hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

Wear resistance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions: a) choosing same dimension specimens for different materials and wear plate producers

b) put them under the same wearing working conditions in our testing equipment.

c) 45 minutes for each specimen.

The blow Test results show that the life span of Wodon wear plate is 2.5 times higher than domestic wear plates and 1.5 times than imported ones.

No. | Wear Plate Art | Test Time | Weight Loss of Overlay |

1 | Wodon wear plate | 45 min | 0.148 g |

2 | Imported wear plate | 45 min | 0.229 g |

3 | Imported wear plate | 45 min | 0.237 g |

4 | Imported wear plate | 45 min | 0.252 g |

5 | Domestic wear plate | 45 min | 0.385 g |

6 | Domestic wear plate | 45 min | 0.377 g |

7 | Domestic wear plate | 45 min | 0.399 g |

8 | Domestic wear plate | 45 min | 0.371 g |

2. Chromium carbide microstructure

The wear resistance of wear plate depends mostly on the hardness, shape, size, amount and distribution of the chromium carbide hard particles.

As you can check on the picture, the prime chromium carbide (Cr7C3) volume fraction on the microstructure is above 50%

3. Bonding strength between the overlay and base plate

The overlay and base plate are very well bonding. The overlay will penetrate into base plate about 0.8 mm~ 1.5 mm, reaching up to 350 Mpa in our tests.

Our own inspection team

We have our own Quality Inspection Technology Department and the team are made of many experience exports with material science bachelor-degree and the leaders with material science master-degree. In the pictures you can also see our equipment in our laboratory. Our inspection team make regular testing on raw material, production process and our products according our company's strict policy.

In our Laboratory there are many equipments to test our products. Portable Spectrum can test easily the chemical composition of wear plate surface . We also bought a new Spectro MAXx (a desktop spark direct reading spectrometer) to read the chemical composition directly from the powder.

We have a series of metallography experiment instruments, so the metallurgical microstructure can be analysed. The chromium carbide volume fraction on the microstructure is above 50%.

We use Rockwell hardness tester to test small sample from our wear plate. The test result are very accurate. We also have portable ultrasonic hardness and thickness testers to test easily the hardness and thickness of wear parts on the scene.

Desktop hardness meter

The desktop Rockwell hardness tester can very accurately measure the hardness of small samples

Ultrasonic hardness tester

The portable ultrasonic hardness tester can easily measure the surface hardness of wear parts on the scene.

Portable spectrum

The portable spectrum can easily test the chemical composition on the scene.

Metallurgical microscope

The metallurgical microscope can test the mircostructure and calculate the chromium carbide volume fraction easily and accurately.

Ultrasonic thickness meter

The portable ultrasonic thickness meter can easily test the thickness of wear plate or work work piece.

Quartz sand rubber wheel abrasion test machine

This model of test machine is not any standard, but it is mainly for contrast reference to test the wear resistance.

Test report of test report

Third Party Inspection

Packaging: Steel pallet, Non fumigation pallets,Customized

Packaging Size: 1.4*3.4, 1.4*.3.0, 1.4*3.5, 2.1*3.5, customized.

Delivery Detail: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Are you trading company or manufacturer ?

A: We are manufacturer with more than 3 factorys, our own sales department and our own inspection technology department.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A:30% T/T in advance, balance against copy of BL.

also, FOB, CIF, CFR all are available for your product.

If you have another question, please feel free to contact us as below:

Send Inquiry to This Supplier

You May Also Like

-

High Resistant and Impact Chromium Carbide Overlay Wear Resistant Plate Bimetal Chute LinersUS$ 180 - 180MOQ: 1 Piece

-

Abrasion Heat Resistance Wear Plate Chromium Carbide Overlay Wear Plate for Screw FeedersUS$ 120 - 120MOQ: 1 Square Meter

-

Hardfacing Cladding Bimetal Wear Plate High Chrome Resistance Wear Plate High Impact for Liner Chutes FeederUS$ 180 - 180MOQ: 1 Piece

-

Wodon Abrasion Resistant Bimetal Cco Wear Plate for Coal Dropping Curve PipeCHF 300 - 300MOQ: 1 Square Meter

-

WD520 Abrasion High Resistance Chromium Carbide Overlay Bimetal Wear Plate for Tractor Shovel LinerUS$ 120 - 120MOQ: 1 Square Meter

-

56-68 HRC Chromium Carbide Overlay Wear Plate Alloy Steel PriceUS$ 299.5 - 299.5MOQ: 1 Square Meter

-

Excellent Wear Resistant Cco Pipe Chromium Carbide Overlay Coated Elbow PipeUS$ 299.5 - 299.5MOQ: 1 Square Meter

-

N400 500 Claded Steel Coil for Cement Factory With Cutting Bending & Welding Services Certified by ASME JIS EN BIS StandardsUS$ 299.5 - 299.5MOQ: 1 Square Meter

-

Wodon Wear Resistant Chromium Carbide Hardened Steel SheetCHF 300 - 300MOQ: 1 Square Meter

-

Chromium Carbide Overlay Abrasion-Resistant Steel Plates Coils ANSI JIS API Certified Cutting Welding Bending ProcessingUS$ 299.59 - 299.59MOQ: 1 Square Meter