Bimetal Chromium Carbide Anti-Wear Resistant Steel Plate Liner ANSI/AISI Standard Certified for Earthmoving Excavator Buckets

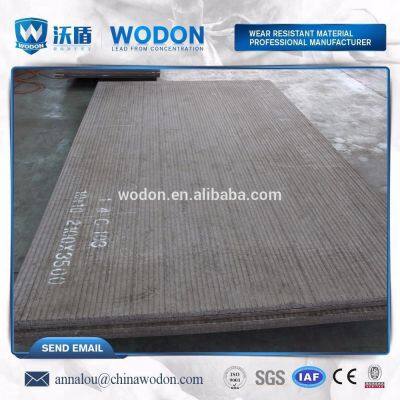

Wear plate size(mm): 1400*3000, 1400*3400, 1400*3500, custermized.

1500*3000,2000*3000, 2100*3500,custermized.

others on request.

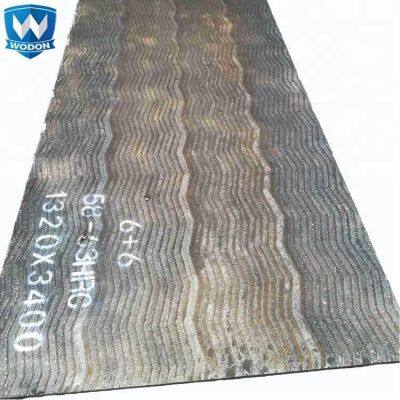

General Description: * The wear plate is manufactured by depositing high chromium, wear resistant materials on the mild steel base plate using open arc or submerged arc welding process. * Consistent wear resistance guaranteed from surface down to 75% depth of the overlay. * The volume fraction of primary carbides is maintained between 30 to 50% to provide a good combination of wear resistance and homogenous bonding. * Plate hardness ranges from HRC58-65. The hardness is tested on machined flat surface just below overlay surface. * Fine cracks perpendicular to the welding bead is normal due to natural stress relieving in a very hard matrix. * Staggered cracking pattern on overlay surface contributes to good formability. * The wear plate is suitable for severe wear and moderate impact applications. | ||

Typical Applications: Wodon plate is widely used in the mining, power plant, port, cement, steel plant, glass, waste handling, glass, dredging, pulp and paper industries. Some applications are as below: * Mining: Hopper and bin liners, Chute and feeder liners, dump truck body liners, dozer blades, shovel buckets, dragline buckets, excavators. * Cement: Separator guide blades, vertical mixer liners, conveying pipelines, screw conveyors, distributors, sintering ore conveying chute, hopper liners * Power: Pipelines, coal feeder chutes, coal hoppers,coal mill shell liner, classifier cones, journal liners, deflectors. * Steel: Bin liners, hopper liners, coke vibrating screen plates, housing liners, sintering fan blade, discharging ducts. | ||

Product name | Wodon Wear Plates | |

Material | Q235/Q345+Chromium carbide overlay alloy | |

Certificate | ISO9001:2008 | |

Chemical composition | C: 3.0~5.0 % Cr: 25~40 % | |

Microstructure | Chromium carbide hard particles volume fraction above 50 % The maximum hardness of chromium carbide is HV 1800 | |

Wear Resistance | Our test shows that the wear resistance of Wodon plate is 30 times higher than low carbon stell and 12 times than heat treated steel | |

Impact resistance | Wodon wear plates can withstand medium impact | |

Temperature resistance | Wodon wear plates can withstand temperatures up to 600 ℃. We can customize high temperature resistance wear plates according to customer's requirements which can withstand maximum terperatures up to 900 ℃ | |

Flatness tolerance | ± 3 mm/m | |

Thickness tolerance | Uniform overlay thickness, with tolerance within 0~0.5 mm | |

Surface treatment | hardfacing, cladding, open arc or submerged arc welding | |

Standard sizes | Open arc welding: 1400*3400 mm, customized Submerged arc welding: 1400*3000 mm, 1400*3500 mm, 2100*3500 mm, customized | |

The main thicknesses (mm) | 3 on 3, 4 on 4, 5 on 5 4 on 6, 5 on 6, 6 on 6, 8 on 6 4 on 8, 5 on 8, 6 on 8, 7 on 8, 8 on 8 4 on 10, 5 on 10, 6 on 10, 7 on 10, 8 on 10, 9 on 10, 10 on 10, 20 on 10 4 on 12, 5 on 12, 6 on 12, 7 on 12, 8 on 12, 10 on 12, 11 on 12, 12 on 12 6 on 14, 8 on 14, 10 on 14 6 on 16, 8 on 16, 10 on 16 6 on 18, 8 on 18, 10 on 18 5 on 20, 6 on 20, 8 on 20, 10 on 20, 20 on 20, 10 on 30, 10 on 40 Customized | |

Product Advantages | 1, Wodon company Cr content in overlay is 25-40%.other company cr content is 10-20%. 2, Wodon company the carbide( cr7c3) volume fraction on the micros tructure is above 50%. other company below 30%. 3, Wodon company hardness HRC58-65. other company hardness below HRC58. 4, Wodon company uniform overlay. other company non-uniform overlay. 5, Wodon company smooth surface. other company uneven. 6, Wodon company high wear resistance. other company poor wear resistance. | |

Thickness(backing plate + overlay) | W x L (mm) | |

4+4, 5+5 | 1,400 x 3,000 | |

6+6, 8+5, 8+6, 8+7, 8+8, etc | 1,400 x 3,500 | |

10+8, 10+9, 10+10, 10+20, 12+12, 12+20, 12+32, 12+50,14+26, 14+32, 20+30, customized thickness | 1,400 x 3,500 2,100 x 3,500 | |

C | 3.5-6.0 | |

Si | 1.0-3.0 | |

Mn | 1.0-3.0 | |

Cr | 27-40 | |

Others | Mo Nb V W Ni B etc | |

Fe | Balance | |

Note: Alloy content varies in different plate thickness. Chemical composition, hardness, alloy content, thickness, size could be customized. | ||

The backing mild steel plate provides Wodon overlay plates with structural integrity, which makes our overlay plates fabricated without damage to welding overlay, regardless of the shape and complexity of the structure. Wodon has the capabilities to manufacture and further process such fabrications or to supply formed, read-to-go wear liners. | ||

Cutting: Wodon overlay plates could be cut by plasma, water-jet, laser. Plasma cutting is the recommended method for cutting our plate. | ||

Drilling: Straight holes and countersunk holes. | ||

Studs Welding: Wodon plate can be fabricated with studs welded to backing of wear plate (M12, M16, M20 and M24), manually or automatically. | ||

Joint Welding: Wodon wear plate can be welded and assembled into kinds of wear parts. | ||

Our factory: Jiangsu Wodon Wear Resistant Material Co. Ltd is located in Jiangsu city, China's northern international shipping center. We are specialized in researching, developing and producing wear resistant products with many years experience in this field. We have more than 300 employees, with an annual capacity 140,000 m² wear plates and 9,000 tons of welding consumables. | ||

Product name | Introduction |

WD-1000/ WD1100 | Common chromium carbide wear plate, suited for use in general wear applications involving low to medium impact. |

WD-1200/ WD1500 | High chromium version of common chromium carbide wear plates, Cr content is high up to above 40%, suited for use in severe abrasion applications,involving low to medium impact. |

WD-1600 | Impact resistant wear plates, independent R&D, suitable for medium to high impact. |

WD-1800 | Heat resistant wear plate, heat resistance maximum up to 900℃. |

WD-NC100 | Crack free wear plate,mainly used as housing liner and side plate in steel mill. |

COther series | Customized on request, special chemical element included for special abrasion fields. |

WD-1000/WD-1100 series Abrasion Resistant Chromium Carbide Overlay plate | ||

WD-1000/WD-1100 is chromium carbide composite cladding fusion bonded to a mild steel backing plate.The deposit has been realized by means of flux cored arc welding .WD-1000/WD-1100 wear plate is suitable for application involving high abrasion and low to medium impact. | ||

Chemical Composition (%) | C: 3.0-5.0 Cr: 17.0-27.0 Mn:1.0-3.0 Si: 1.0-3.0 Fe: Bal. Other---- | |

Hardness | HRC 58-65 | |

Standard Thickness ( mm) | 3+3, 4+4, 5+5,6+4, 6+6,8+4,8+6,8+8,10+10,12+12, etc ( overlay thickness up to 50mm). | |

Standard Sheet Size (mm) | 1400*3400, 1500*3000,2000*3000 (Customized size available). | |

ASTM G65 Procedure A | 0.12-0.18g | |

Operating Temperature | <400℃ | |

Base Metal Material | Q235B,Q345B,A36,S235JR and struction steels. | |

Main Industry | Mining, glass industry, cement plant,steel mill, power plant, etc. | |

Fabrication | Plasma cutting,Gouging, Countersunk , stud bolt, Bending. | |

WD-1200/WD-1500 series Abrasion Resistant Chromium Carbide Overlay plate | ||

WD-1200/WD-1500 is chromium carbide composite cladding fusion bonded to a mild steel backing plate.The deposit has been realized by means of submerged arc welding .WD-1200/WD-1500 wear plate is suitable for application involving severe abrasion and low to medium impact. | ||

Chemical Composition (%) | C: 3.0-6.0 Cr: 25.0-45.0 Mn:1.0-3.0 Si: 1.0-3.0 Fe: Bal. Other---- | |

Hardness | HRC 58-65 | |

Standard Thickness ( mm) | 4+4, 5+5,6+4, 6+6,8+4,8+6,8+8,10+10,12+12, 12+17,etc ( overlay thickness up to 50mm). | |

Standard Sheet Size (mm) | 1400*3500, 2100*3500 (Customized size available). | |

Micro structure | Carbide volume fraction up to 50%. | |

ASTM G65 Procedure A | 0.09-0.16g | |

Operating Temperature | <400℃ | |

Base Metal Material | Q235B,Q345B,A36,S235JR and struction steels. | |

Main Industry | Mining, glass industry, cement plant,steel mill, power plant, etc. | |

Fabrication | Plasma cutting,Gouging, Countersunk , stud bolt, Bending. | |

WD-1600 series Abrasion Resistant Chromium Carbide Overlay plate | ||

WD-1600 is chromium carbide composite cladding fusion bonded to a mild steel backing plate.The deposit has been realized by means of submerged arc welding .WD-1600 wear plate is suitable for application involving high abrasion and medium to high impact. | ||

Chemical Composition (%) | C: 3.5-6.5 Cr: 25.0-45.0 Mn:1.0-3.0 Si: 1.0-3.0Mo+Nb--- Fe: Bal. | |

Hardness | HRC 58-65 | |

Standard Thickness ( mm) | 4+4, 5+5,6+4, 6+6,8+4,8+6,8+8,10+10,12+12, 12+17,etc ( overlay thickness up to 50mm). | |

Standard Sheet Size (mm) | 1400*3500, 2100*3500 (Customized size available). | |

Micro structure | Carbide volume fraction up to 50%. | |

ASTM G65 Procedure A | 0.09-0.16g | |

Operating Temperature | <400℃ | |

Base Metal Material | Q235B,Q345B,A36,S235JR and struction steels. | |

Main Industry | Mining, glass industry, cement plant,steel mill, power plant, etc. | |

Fabrication | Plasma cutting,Gouging, Countersunk , stud bolt, Bending. | |

WD-1800 series Abrasion Resistant Chromium Carbide Overlay plate | ||

WD-1800 is complex carbide composite cladding fusion bonded to a mild steel backing plate.WD-1800 wear plate is suitable for application involving high abrasion at elevated temperature up to 900℃。 | ||

Chemical Composition (%) | C: 4.0-7.0 Cr: 25.0-40.0 Mn:--- Si: ---Mo+Ni+V+Nb+W--- Fe: Bal. | |

Hardness | HRC 58-65 | |

Standard Thickness ( mm) | 6+6,8+6 8+8,10+10,12+12, 12+17,14+26, 12+32, etc ( overlay thickness up to 50mm). | |

Standard Sheet Size (mm) | 1400*3500, 2100*3500 (Customized size available). | |

Micro structure | Carbide volume fraction up to 50%. | |

ASTM G65 Procedure A | 0.09-0.16g | |

Operating Temperature | <900℃ | |

Base Metal Material | Q235B,Q345B,A36,S235JR and struction steels. | |

Main Industry | Mining, glass industry, cement plant,steel mill, power plant, etc. | |

Fabrication | Plasma cutting,Gouging, Countersunk , stud bolt, Bending. | |

Abrasion Resistant Chromium Carbide Overlay plates | ||||||

Model | Characteristics | Chemical Composition (%) | Operating Temperature | |||

WD-1000/WD-1100 | WD-1000/WD-1100 is chromium carbide composite cladding fusion bonded to a mild steel backing plate.The deposit has been realized by means of flux cored arc welding .WD-1000/WD-1100 wear plate is suitable for application involving high abrasion and low to medium impact. | C: 3.0-5.0 Cr: 17.0-27.0 Mn:1.0-3.0 Si: 1.0-3.0 Fe: Bal. Other---- | <400℃ | |||

WD-1200/WD1500 | WD-1200/WD-1500 is chromium carbide composite cladding fusion bonded to a mild steel backing plate.The deposit has been realized by means of submerged arc welding .WD-1200/WD-1500 wear plate is suitable for application involving severe abrasion and low to medium impact. | C: 3.0-6.0 Cr: 25.0-45.0 Mn:1.0-3.0 Si: 1.0-3.0 Fe: Bal. Other---- | <400℃ | |||

WD-1600 | WD-1600 is chromium carbide composite cladding fusion bonded to a mild steel backing plate.The deposit has been realized by means of submerged arc welding .WD-1600 wear plate is suitable for application involving high abrasion and medium to high impact. | C: 3.5-6.5 Cr: 25.0-45.0 Mn:1.0-3.0 Si: 1.0-3.0Mo+Nb--- Fe: Bal. | <600℃ | |||

WD-1800 | WD-1800 is complex carbide composite cladding fusion bonded to a mild steel backing plate.WD-1800 wear plate is suitable for application involving high abrasion at elevated temperature up to 900℃. | C: 4.0-7.0 Cr: 25.0-40.0 Mn:--- Si: ---Mo+Ni+V+Nb+W--- Fe: Bal. | <900℃ | |||

WD-NC100 | Crack free wear plate,mainly used as housing liner and side plate in steel mill. | 0.09-0.16g | ||||

Other Series | Customized on request,special chemical element included for special abrasion fields. | <900℃ | ||||

Sheet size | 1400*3400mm, 1400*3000mm,1500*3000mm,1400*3500mm,2000*3000mm,2100*3500mm, other on request. | |||||

Base metal material | Q235,Q345 and so on. | |||||

Overlay thickness | 3-50mm. | |||||

1. screen plate/vibrating plate

2. proetection cover

3. bolt embedded in the back

4. round to square transition

5. bend

6. trough

1,Drilling Holes

2, Bolt embedded welding in the back

3,Bending

4,Welding

5,Paint Spraying

6,Diamond Grid

Packaging Size: 1.4*3.4 m, 1.4*.3.0 m, 1.4*3.5 m, 2.1*3.5 m, customized.

Delivery Detail: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is

according to quantity.

Loading into 20 ft or 40 ft container.

We can provide steel pallet design or product the steel pallet according to customer's drawing, so that our product can be safety.

surpported and easly transported with steel tape and iron ecke. We can provide our product with printing to rust protection.

1. The overlay chemical composition is the key.

The main ingredients of Wodon plates are C: 3.0~5.0% and Cr: 25~40%. This chemical proportion results in a large amount of prime chromium carbide (Cr7C3) hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

Wear resistance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions:

b) put them under the same wearing working conditions in our testing equipment.

c) 45 minutes for each specimen.

The blow Test results show that the life span of Wodon wear plate is 2.5 times higher than domestic wear plates and 1.5 times than imported ones.

Wear Plate Art | Test | Weight Loss of |

Wodon wear plate | 45 min | 0.148 g |

Imported wear plate | 45 min | 0.229 g |

Imported wear plate | 45 min | 0.237 g |

Imported wear plate | 45 min | 0.252 g |

Domestic wear plate | 45 min | 0.385 g |

Domestic wear plate | 45 min | 0.377 g |

Domestic wear plate | 45 min | 0.399 g |

Domestic wear plate | 45 min | 0.371 g |

Applications | ||

We are a professional manufacture of chromium carbide overlay wear plates ( 9 on 10, 17 on 12 , 26 on 14 etc ) & Flux cored welding wires that widely apply to steel, mining, coal, cement, power, oil, port . | ||

Applications-Cement industry | Powder concentrator blade,impact plate, pipeline, pump shell, mill liner, crusher parts, slag notch, bottom plate, vibrating screen, distributor, converying pipeline, separator, fan shell, cutting edge, augers, ball mill feed inlet, conveying liners, squeeze roller hardfacing, grinding roller hardfacing. | |

Applications-Mining industry | Truck liner, hopper liner, chute feeder liner, cover plate,wear bar and wear plate,excavator bucket, loader shovel, crawler loader, loader bucket, bulldozers bucket, dragline bucket, chute feeder ,hopper, crusher parts and liners, coal conveying pipe, elbow, scraper conveyor bottom plate, pump. | |

Applications-Port conveying | Iron ore,coal and other bulk cargo handling system, grad bucket, hopper , chute and other components that suffer wear problems.It is very important to apply wear plates on the easy wearing parts in order to extend their service life and reduce the downline. | |

Applications-Power industry | Fan blade,bumer pipeline, chute feeder , hopper liner crusher parts,coal mill parts, dust pipe, air handing systems , converyor chute , pipe-troughing system ,coal feeder chute, feed pipe chute, grad feeder chute, coal feeder pipe , separator cones, coal funnel, fuel conveyor pipe, exhaust fan blade, coal mill barrel lining ,coal mill roller head liner, coal drop pipe wear resistant elbow, coal mill internal liner, deflector, air distributing ring ,coal chute,wear resistant nozzle stub, burner barrel, burner elbow. | |

Applications-Steel industry | Bin liner, sliding slope, mesh screen, blast boiler inverted bucket, skip car , blast boiler reinforced plate, sintering feed tube, pipeline , feed plate, hopper liner , sluiceway chute, discharge duct, chute, screen plate, sintering fan blade, blast furnace charging bucket liner, steel slag grinding mill hardfacing, roller reparing for 4- roll crusher , single roller repairing for sintering machine, single roll comb board reparing. | |

provides study opportunites, continuously improves welfare and work environment. To the pursuit of perfect quality and customer satisfaction, we have certified with ISO9001 quality management system, ISO14001 environmental management system, OHSAS18001 occupational health and safety management system. We sincerely provide high quality wear resistant products and services to customers. We will always supply our best products, adhere to quality first and keep up the spirit of striving for perfection.We use our own developed CNC automatic welding machine with multi welding guns to weld our own hardface wear plate. These can overcome the problems like: low productivity, poor flatness and overlay falling off etc. This is a high automation level machine, each welding gun can operate independently and restart exactly from the point it had stopped, simplifying the operation process.

in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company’s technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.4 Major production bases: Jiangsu, Hebei, Hunan, Jiangsu. 68 Wear plate production lines (over 130 welding torches). 5 Welding wire production lines.Annual output of chromium carbide wear plates: 200,000 square meters

Annual output of flux cored hardfacing wires: 9000 tons.

A:We are based in Jiangsu, China, start from 2014,sell to Domestic Market,Oceania,North America,South

Q:how can we guarantee quality?

Q:what can you buy from us?

A:Chromium Carbide Overlay Plate,Wear Plate Liner,Flux Cored Welding Wire

Q:why should you buy from us not from other suppliers?

A:The chromium content as high as 25~50% in the overlay The chromium carbide (Cr7C3) volume fraction above 50% Uniform distribution and high hardness HRC 58~65 Smooth surface, thickness tolerance +0~+0.5 mm only Flatness tolerance -3~+3 mm/m

Accepted Payment Currency:USD,AUD,CNY;

Accepted Payment Type: T/T,L/C,Cash;

Language Spoken:English,Chinese,Spanish,Portuguese,German

Send Inquiry to This Supplier

You May Also Like

-

Wodon Bimetallic Chromium Carbide Wear-resistant Steel PlatesCHF 300 - 300MOQ: 1 Square Meter

-

Wodon Bimetal CCO Wear Plate Abrasion Resistant With Custom Processing Services Cutting Welding Punching BendingCHF 300 - 300MOQ: 1 Square Meter

-

Wodon Bimetallic Chromium Carbide Plate Abrasion Resistant Buckets ASTM Various Include Cutting Welding Bending PunchingCHF 300 - 300MOQ: 1 Square Meter

-

High Impact and Abrasion Hardfacing Chromium Carbide Overlay Wear Steel Plate DimetalUS$ 299.99 - 299.99MOQ: 1 Square Meter

-

High Chromium Carbide Overlay Mild Steel Wear Resistant Bimetal for Ball Mill Liner PlatesUS$ 180 - 180MOQ: 1 Piece

-

Hardfacing Cladding Bimetal Wear Plate High Chrome Resistance Wear Plate High Impact for Dump Truck Tray LiningsUS$ 180 - 180MOQ: 1 Piece

-

High Resistant and Impact Chromium Carbide Overlay Wear Resistant Plate Bimetal Chute LinersUS$ 180 - 180MOQ: 1 Piece

-

Abrasion Heat Resistance Wear Plate Chromium Carbide Overlay Wear Plate for Screw FeedersUS$ 120 - 120MOQ: 1 Square Meter

-

Hardfacing Cladding Bimetal Wear Plate High Chrome Resistance Wear Plate High Impact for Liner Chutes FeederUS$ 180 - 180MOQ: 1 Piece

-

Wodon Abrasion Resistant Bimetal Cco Wear Plate for Coal Dropping Curve PipeCHF 300 - 300MOQ: 1 Square Meter