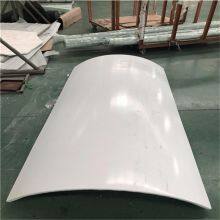

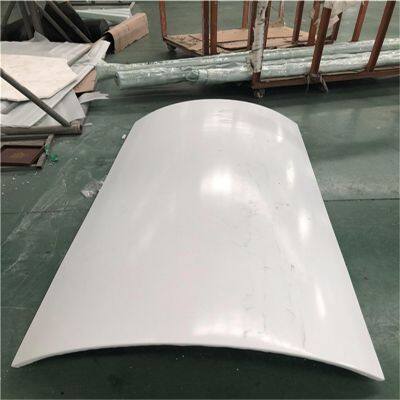

Enamelled pressed steel sheets are advanced composite materials that combine the strength and durability of steel with the protective and aesthetic qualities of an enamel coating. These sheets are valued for their outstanding mechanical performance, vibrant color options, and adaptability to a wide range of applications, making them a preferred choice across construction, infrastructure, and decorative industries.

1. Structural Characteristics

Enamelled pressed steel sheets are composed of two key components:

Steel Substrate:

The core of the material is high-quality pressed steel, providing excellent structural strength, rigidity, and durability. The steel base is typically made from mild steel or stainless steel, depending on the specific requirements of the application.

Enamel Coating:

The surface layer is created by fusing a glass-based enamel material onto the steel sheet at extremely high temperatures, usually between 800°C and 900°C.

This process creates a robust, smooth, and non-porous coating that adheres permanently to the steel, offering protection and an attractive finish.

The fusion of enamel and pressed steel results in a material that combines the toughness of metal with the resilience and visual appeal of enamel.

2. Color and Size Customization

Enamelled pressed steel sheets offer extensive flexibility in design, including:

Color Options:

Available in a wide range of colors, including standard solid hues, vibrant custom shades, and metallic finishes.

The enamel coating retains its color permanently, ensuring no fading or discoloration over time, even when exposed to sunlight or harsh environments.

Surface Finishes:

The sheets can feature glossy, matte, or textured finishes, providing aesthetic options to match the design intent of any project.

Patterns, graphics, and logos can also be applied to the surface for branding or decorative purposes.

Size Customization:

Standard and bespoke sizes can be provided, with options to fabricate large sheets or precision-cut smaller panels.

Sheet thickness typically ranges from 0.6 mm to 1.5 mm, depending on the application requirements.

This level of customization makes enamelled pressed steel sheets suitable for a variety of architectural and industrial needs.

3. Physical Performance

Enamelled pressed steel sheets are recognized for their superior physical properties, which ensure long-term performance and minimal maintenance:

Mechanical Strength:

The pressed steel substrate provides high load-bearing capacity, structural stability, and resistance to deformation.

Durability:

The enamel coating protects the steel from scratches, abrasions, and mechanical impacts, ensuring a long service life.

Corrosion Resistance:

The enamel layer acts as a barrier against moisture, chemicals, and pollutants, preventing rust and corrosion even in humid or industrial environments.

Fire Resistance:

Enamelled steel sheets are non-combustible and withstand high temperatures without warping or releasing toxic fumes, making them ideal for fire-rated applications.

Weather and UV Resistance:

The enamel coating resists UV rays, extreme weather conditions, and temperature variations, making the sheets suitable for both indoor and outdoor use.

Hygienic and Easy to Clean:

The non-porous, smooth enamel surface prevents dirt, bacteria, and mold accumulation, ensuring excellent hygiene and easy cleaning.

Chemical Resistance:

Resistant to acids, alkalis, and solvents, enamelled steel sheets perform well in chemically aggressive environments.

4. Application Fields

Thanks to their exceptional performance and visual appeal, enamelled pressed steel sheets are widely used across a variety of industries and sectors, including:

Architecture and Construction:

Exterior cladding for buildings and facades

Interior wall panels and decorative finishes

Roofing and ceiling systems

Infrastructure:

Subway stations, tunnels, and pedestrian bridges

Noise barriers along highways and railways

Walls and surfaces in airports and railway terminals

Industrial Applications:

Cladding for storage tanks, silos, and machinery

Protective surfaces in chemical plants and food processing facilities

Fire-resistant partitions and enclosures

Commercial Spaces:

Signage, display panels, and advertising boards

Decorative elements in malls, hotels, and office buildings

Hygienic surfaces in kitchens, laboratories, and hospitals

Public Art and Custom Design:

Murals, public art installations, and creative design features

Custom panels with logos, branding, or graphic elements

5. Key Usage Areas

Enamelled pressed steel sheets can be used in various functional and decorative areas, including:

Exterior Applications:

Building facades and roofing systems that require durability, weather resistance, and a striking visual appeal.

Infrastructure components such as tunnel linings, bridges, and noise barriers that demand longevity and minimal maintenance.

Interior Applications:

Wall cladding, ceiling panels, and decorative finishes in commercial and residential spaces.

Elevator interiors, column covers, and feature walls for a polished, modern look.

Specialized Environments:

Fire-resistant panels in industrial settings and public spaces.

Hygienic, easy-to-clean surfaces in hospitals, laboratories, and food processing plants.

Conclusion

Enamelled pressed steel sheets offer a unique combination of structural strength, durability, and aesthetic versatility. By fusing a robust pressed steel substrate with a high-performance enamel coating, these sheets provide unmatched resistance to environmental and mechanical stress while maintaining vibrant, long-lasting visual appeal.

Their flexibility in design, low maintenance requirements, and suitability for diverse applications make them an ideal solution for architects, designers, and engineers looking to combine performance with aesthetics. Whether used in construction, infrastructure, or industrial projects, enamelled pressed steel sheets deliver superior functionality and timeless beauty.

China. Tangshan Ruierfa New Materials welcomes friends from all over the world to become partners! Welcome to consult and negotiate.

Send Inquiry to This Supplier

You May Also Like

-

Glass-Enamel Panel FactoryUS$ 44 - 47MOQ: 10 Square Meters

-

Supply of Clean Glass-Faced Enameled Steel PlatesUS$ 44 - 47MOQ: 10 Square Meters

-

High Quality Glossy Mirror Thick SA-240 Stainless Steel Sheets Plates for PVC Card Press LaminatingNegotiableMOQ: 1 Ton

-

W12 Cone Industrial Steel Cold Aluminium Plate Sheet Press Bending Rolling MachineNegotiableMOQ: 1

-

Industry Use Bolted Enameled Pressed Steel TankUS$ 160,000 - 200,000MOQ: 1 Set

-

Cold Pressed Stainless Steel SheetUS$ 1,000 - 2,100MOQ: 30 Tons

-

Color Coated Steel Sheet Tile Press MachineUS$ 3,000 - 3,000MOQ: 1 Set

-

OEM Metal Pressing Parts, Punching Metal Sheet Parts,steel Sheet StampingUS$ 5.38 - 21.56MOQ: 195 Pieces

-

Hot Sale Stainless Steel Pizza Dough Sheet Pressing Machine With Best ServiceUS$ 2,000 - 3,000MOQ: 1 Set

-

Enamelled Pressed Steel SheetUS$ 44 - 47MOQ: 10 Square Meters