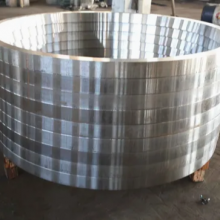

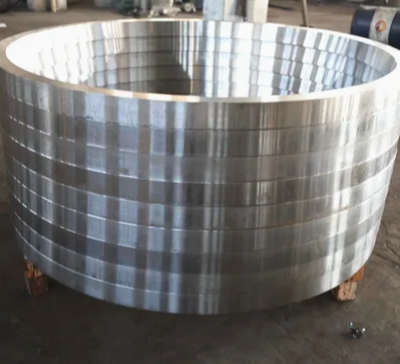

Professional Gear Ring Forged Ring Forging Forged Seamless Rolled Rings Sleeve 42CrMo4 Forging Parts Forged Large Ring Sleeve

Professional Gear Ring Forged Ring Forging Forged Seamless Rolled Rings sleeve 42CrMo4 Forging Parts Forged Large Ring sleeve

Professional Gear Ring Forged Ring Forging Forged Seamless Rolled Rings sleeve 42CrMo4 Forging Parts Forged Large Ring sleeve

The forging process

Bringing steel into shape – the hot forging process

During the forging process, ingots or pre-forged bars are reheated to temperatures near two-thirds of the melting point of steel. This makes the material malleable and allows the forge masters to bring steel into shape.

This process is called thermo-plastic deformation, during which the underlying grain and texture of the material are reformed and lead to unrivalled mechanical properties. The deformation of the material leads to a fine grain structure, leading to a tough and ductile material response.

During the forging process, the material cools down and needs to be reheated, often multiple times for one part. Experienced forge masters can tell by the color of the glow whether the material is still hot enough for processing.

After forging, the material is subject to thermal treatment. This process ensures that the steel is in the right state – ferrite, austenite or martensite, and sometimes even multiple phases (for instance in Duplex who features austenite and ferrite) of them depending on the composition and the required properties. The latter depend on the sequence of heating and cooling and the rates of temperature change – Processes that the producers must master and that require special equipment for different cases and sizes.

Clearly, forging and thermal treatment are complex matters and require years of expertise and mastery to craft a high-quality product. That is why we only work with qualified and audited suppliers!

Professional Forging Hot Forging Parts Non-Standard Processing Mold Forged Sleeve Ring

Professional Gear Ring Forged Ring Forging Forged Seamless Rolled Rings sleeve 42CrMo4 Forging Parts Forged Large Ring sleeve

ING ROLLED FORGING

Ring rolled forging is produced from bar stocked, upset, pierced and ring rolled to meet ID and OD requirements.

Ring rolling is using a ring of smaller diameter, rolling into a precise ring of larger diameter and a reduced cross section. This is accomplished by the use of two rollers, one driven and one idle, acting on either side of the ring’s cross section

Advantages of Ring Rolled Forging:

The forming of the material will impart the ring with a grain orientation that gives it enhanced strength relative to most applications

Common Application:

Casing Connectors;

Gears;

Spacers;

FORGING

It is a hot forming of metal into a required geometry to achieve a desired strength in mechanical properties

Value Added Services:

Customised Chemistry Composition

Induction Hardening

Deep Hole Drilling

Semi-Finish / Finish Machining

Material:

Alloy Steel (4130, 4140, 4145H, 4340, 8630, F22 etc)

Stainless Steel (304, 316/316L, 317/317L, 321 410 439 etc)

Special Steel (Duplex , Super Duplex,

Nickel Alloy, Inconel 600 625 718 Incoloy 800/H 825 926 etc)

Customised Steel Grade to your requirements.

Welcome to discuss it at wechat/whatsapp: +8615000496712

Send Inquiry to This Supplier

You May Also Like

-

High Quality Nickel Alloys/ Monel Wire Inconel 600 Wire CoilNegotiableMOQ: 1 Piece

-

High Quality Nickel Alloys/ Monel Wire Inconel X-750 UNS N07750Wire CoilNegotiableMOQ: 1 Piece

-

High Quality Nickel Alloys/ Monel Wire Monel 400 UNS N04400 Wire CoilNegotiableMOQ: 1 Piece

-

Professional Forging Hot Forging Parts Non-Standard Processing Mold Forged Sleeve RingNegotiableMOQ: 1 Piece

-

Professional Forging Hot Forged Stainless Steel Ring Sleeve Stainless Steel Ring Forging Oem Customized Forging RingNegotiableMOQ: 1 Piece

-

Professional Forging Hot Forged SS Ring Sleeve Super Duplex Stainless Steel Ring Forging Oem Customized Forging Ring SleeveNegotiableMOQ: 1 Piece

-

Professional Forging Hot Forged SS Ring Sleeve Nickel Alloy Titanium Alloy Ring Forging Oem Customized Forging Ring SleeveNegotiableMOQ: 1 Piece

-

ASME B31.3 B 16.5 Customized Spool Flange-flange SS/Nickel Alloy Pipe Fabrication Elbow Flange Spool End Pipe Spool PrefabricationUS$ 40 - 80MOQ: 1 Piece

-

1/4 1/8 3/8 1/2 3/4 Male Thread, BSPP/BSPT/ Metric/NPT SS304 SS316 FORGED Pipe Fitting Hex Nipple Hydraulic Fittings Hydraulic AdaptersNegotiableMOQ: 1 Piece

-

Factory Wholesale Hydraulic Hose Fittings High Pressure Ferrule Fitting SetUS$ 1 - 8MOQ: 1 Piece