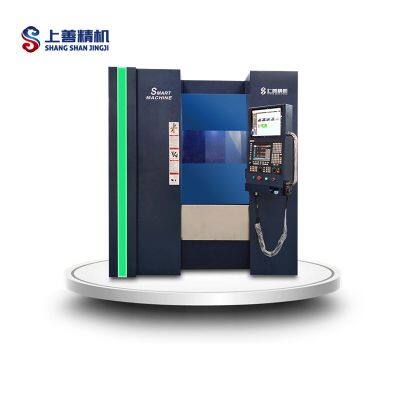

CNC Milling Machine 5 Axis CNC Machining Center for Graphite S-1680G

X/Y/ZTravel: 1600×800×600mm

TableDimensions: 1600×1300mm

Max.TableLoad: 3000Kg

SpindleFacetoWorktableHeight: 220—820mm

PositioningAccuracy: ±0.005/300mm

Repeatability: ±0.003/300mm

ToolCapacity: 24

SpindleSpeed: 15000-20000Rpm

MovingSpeed: 24m-36m/min

CuttingSpeed: 10m-20m/min

ToolChangeTime: 2seconds

Dimensions(L/W/H): 5200×4200×3850mm

MachineToolWeight: 9000Kg

ControlMethod: Fullyclosed-loopcontrol

If necessary, please contact me WhatsAPP:8613510109008,

Email:sales@ssjjcnc.ru.

Looking for a CNC Milling Machine 5 Axis CNC Machining Center for Graphite that delivers precision, efficiency, and exceptional performance? Our advanced 5 Axis CNC Machining Center is specifically designed for graphite machining, offering unparalleled accuracy and versatility for industries such as electronics, automotive, aerospace, and mold making. This CNC milling machine is built to handle the unique challenges of graphite machining, providing high-speed, high-precision cutting for complex graphite molds, graphite electrodes, and custom graphite parts.

The 5-axis CNC machining center enables simultaneous movement along five axes, allowing for the production of intricate graphite components with tight tolerances and superior surface finishes. Whether you're working with graphite electrodes for EDM or creating complex graphite molds, this machine offers the flexibility to perform complex cuts, curves, and angles in a single setup, reducing production time and increasing overall efficiency.

Key Features of Our CNC Milling Machine 5 Axis CNC Machining Center for Graphite:

1.5-Axis Simultaneous Machining: The 5-axis capability allows for precise and intricate machining of graphite materials, enabling multi-dimensional cuts, sharp edges, and complex curves in a single setup—ideal for graphite molds and electrodes.

2.High-Speed, High-Precision Cutting: With advanced CNC technology and high-speed spindles, this CNC milling machine offers fast material removal and fine precision, producing high-quality finishes on graphite parts with tight tolerances.

3.Enhanced Efficiency: The ability to perform complex cuts in fewer setups results in significant time savings and higher production efficiency, making it perfect for industries requiring rapid prototyping and high-volume production of graphite components.

4.Advanced CNC Control System: The user-friendly CNC control system ensures easy programming, setup, and operation, making it easier for operators to achieve precise results with minimal training.

5.Built for Durability: Designed to withstand the abrasive nature of graphite, this CNC machining center features a robust construction that enhances durability, reduces wear, and ensures long-lasting performance.

6.Effective Dust Collection: Equipped with an integrated dust extraction system, the machine captures fine graphite dust, maintaining a clean workspace, enhancing operator safety, and prolonging the machine's lifespan.

7.Versatile

Send Inquiry to This Supplier

You May Also Like

-

5-Axis Simultaneous Control Compact Machining Center S-2500GNegotiableMOQ: 1 Unit

-

3-AXIS CNC HIGH SPEED GRAPHITE MACHINING CENTER S-1200GNegotiableMOQ: 1 Unit

-

CNC Graphite Machining Equipment S-1000GNegotiableMOQ: 1 Unit

-

CNC Graphite Milling and Machining S-1350GNegotiableMOQ: 1 Unit

-

Graphite Cutting Center S-1680GNegotiableMOQ: 1 Unit

-

CNC Graphite Milling and Machining Center S-2500GNegotiableMOQ: 1 Unit

-

Gantry Graphite CNC Milling Machine S-1200GNegotiableMOQ: 1 Unit

-

Graphite Gantry Machine Tool S-1000GNegotiableMOQ: 1 Unit

-

Graphite Gantry Engraving and Milling Machine S-1350GNegotiableMOQ: 1 Unit

-

Graphite Processing Gantry Machine Tool S-1680GNegotiableMOQ: 1 Unit