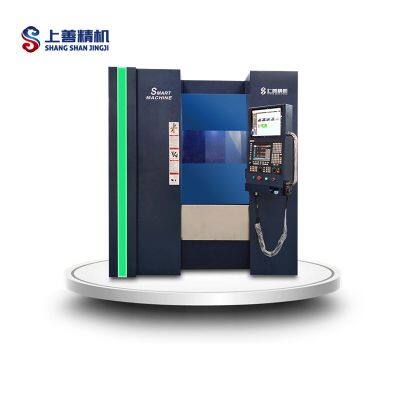

Longmen Graphite Machine Center 3 Axis Machining S-1000G

X/Y/ZTravel: 1000×820×350mm

TableDimensions: 1020×820mm

Max.TableLoad: 800Kg

SpindleFacetoWorktableHeight: 95—445mm

PositioningAccuracy: ±0.005/300mm

Repeatability: ±0.003/300mm

ToolCapacity: 24

SpindleSpeed: 24000-40000Rpm

MovingSpeed: 24m-36m/min

CuttingSpeed: 10m-20m/min

ToolChangeTime: 2seconds

Dimensions(L/W/H): 2700×2300×2600mm

MachineToolWeight: 5200Kg

ControlMethod: Fullyclosed-loopcontrol

If necessary, please contact me WhatsAPP:8613510109008,

Email:sales@ssjjcnc.ru.

Looking for a Longmen Graphite Machine Center with 3-Axis Machining? Our Longmen Graphite Machining Center is a cutting-edge solution designed for high-precision graphite machining. Engineered with 3-axis CNC technology, this machine delivers exceptional performance and accuracy in the production of graphite electrodes, graphite molds, and custom graphite parts. Perfect for industries like aerospace, electronics, automotive, and tooling, the Longmen Graphite Machine Center offers outstanding versatility and efficiency in machining complex graphite components.

The 3-axis configuration provides superior stability, precise motion control, and the ability to handle intricate graphite materials with ease. Whether you're producing graphite electrodes for EDM (Electrical Discharge Machining) or creating high-precision graphite molds, this machine ensures clean, smooth cuts and excellent surface finishes. Its robust design is specifically built to handle the unique challenges of machining graphite, a material known for its abrasiveness and delicate nature.

Key Features of the Longmen Graphite Machine Center (3-Axis Machining):

High-Precision 3-Axis CNC Controls: The Longmen Graphite Machine Center features advanced 3-axis CNC technology, providing unmatched accuracy and repeatability for machining graphite electrodes, graphite molds, and other custom graphite parts.

2.Efficient Dust Collection System: This machine comes equipped with an integrated dust collection system that effectively captures graphite dust during the machining process, maintaining a cleaner work environment and ensuring the longevity of the equipment.

3.Durability for Graphite Machining: Built to withstand the wear and tear of graphite machining, the Longmen Graphite Machine Center offers a durable, rigid structure designed for long-lasting performance, even under the demanding conditions of high-volume production.

4.Excellent Surface Finish: Thanks to its precise motion control and high-speed cutting capabilities, the machine ensures superior surface finishes on complex graphite components, reducing the need for additional finishing processes.

5.User-Friendly Interface: The CNC control system is intuitive and easy to use, reducing setup times and ensuring efficient operations, even for operators with minimal experience.

Send Inquiry to This Supplier

You May Also Like

-

CNC Graphite Milling and Machining S-1350GNegotiableMOQ: 1 Unit

-

Graphite Cutting Center S-1680GNegotiableMOQ: 1 Unit

-

CNC Graphite Milling and Machining Center S-2500GNegotiableMOQ: 1 Unit

-

Gantry Graphite CNC Milling Machine S-1200GNegotiableMOQ: 1 Unit

-

Graphite Gantry Machine Tool S-1000GNegotiableMOQ: 1 Unit

-

Graphite Gantry Engraving and Milling Machine S-1350GNegotiableMOQ: 1 Unit

-

Graphite Processing Gantry Machine Tool S-1680GNegotiableMOQ: 1 Unit

-

Graphite Processing Engraving Machine S-2500GNegotiableMOQ: 1 Unit

-

Processing Graphite With Gantry Machine Tool S-1200GNegotiableMOQ: 1 Unit

-

CNC Gantry Milling Machine for Graphite Processing S-1000GNegotiableMOQ: 1 Unit