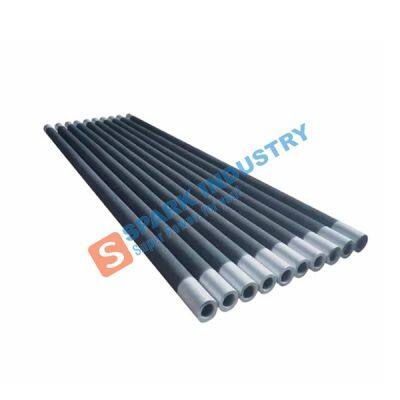

ED Type Silicon Carbide Rod

Silicon carbide rods, also known as silicon carbide heating element is the use of high-quality green silicon carbide as the main raw material, the processing system also, high-temperature silicification, recrystallization of rod-shaped non-metallic high-temperature heating components. Compared with the metal heating element, silicon carbon rod has the characteristics of high temperature, anti-oxidation, corrosion resistance, long life, small deformation, easy installation and maintenance. Therefore, silicon carbon rods are widely used in magnetic materials, powder metallurgy, ceramics, glass, metallurgical and mechanical industries such as a variety of high-temperature electric furnace and other electric heating equipment. The ED type is the standard SiC heating element. A high-density self-bonded silicon carbide element, ED type is available in a large range of diameters and lengths.

Type: ED (Equal Diameter); OD: Outer Diameter; HZ: Hot Zone; CZ: Cold Zone; OL: Overall Length; Resistance; Ohms (Ω)

Examples: Type ED with 54mm-OD, 1600mm-HZ, 400mm-CZ, 2400mm-OL, Resistance 0.90Ω

Specified as;

ED, OD /Hot Zone length/Overall length/resistance

ED 54/1600/2400/0.90

SiC Silicon Carbide Heating Element Features

1, High temperature resistance, resistance to oxidation and corrosion

2, Fast heating, long life, small deformation at high temperature, easy to install and maintain

3, With automatic electronic control systems, precision constant temperature can be obtained, curve temperature control can be obtained too according to the needs of production

Outer Diameter | Hot zone | Cold zone | Overall length | Range of resistance |

8 | 100-300 | 60-200 | 240-700 | 2.1-8.6 |

14 | 100-500 | 150-350 | 400-1200 | 0.7-5.6 |

16 | 200-600 | 200-350 | 600-1300 | 0.7-4.4 |

18 | 200-800 | 200-400 | 600-1600 | 0.7-5.8 |

20 | 200-800 | 250-600 | 700-2000 | 0.6-6.0 |

25 | 200-1200 | 250-700 | 700-2600 | 0.4-5.0 |

30 | 300-2000 | 250-800 | 800-3600 | 0.4-4.0 |

35 | 400-2000 | 250-800 | 900-3600 | 0.5-3.6 |

40 | 500-2700 | 250-800 | 1000-4300 | 0.5-3.4 |

45 | 500-3000 | 250-750 | 1000-4500 | 0.3-3.0 |

50 | 600-2500 | 300-750 | 1200-4000 | 0.3-2.5 |

54 | 600-2500 | 300-750 | 1200-4000 | 0.3-3.0 |

Send Inquiry to This Supplier

You May Also Like

-

DB ( Dumbbell ) Type Silicon Carbide Heating Element for FurnacesUS$ 10 - 50MOQ: 10 Pieces

-

Strong Acid Resistance G Type SiC Heating ElementsUS$ 10 - 50MOQ: 10 Pieces

-

High Purity Alpha Silicon M Type SiC Heating Element 1600℃US$ 10 - 50MOQ: 10 Pieces

-

Rod Shaped Non-Metallic High-Temperature Electric Heating Element (Non-Standard Customization)US$ 10 - 50MOQ: 10 Pieces

-

ED Type Silicon Carbide Rod High-density Self-bondedUS$ 10 - 50MOQ: 10 Pieces

-

SG Type SiC Heating Element Oxidizing Atmosphere 1450°CUS$ 10 - 50MOQ: 10 Pieces

-

SGR Type SiC Heating Elements Fast Heating Long Life 1500 Deg C.US$ 10 - 50MOQ: 10 Pieces

-

U Type Silicon Carbide Rod Cold Ends Metallized With AluminumUS$ 10 - 50MOQ: 10 Pieces

-

W Type SiC Heating Elements Withstands as High as 1500°CUS$ 10 - 50MOQ: 10 Pieces

-

1500 Long Service Life H Type Silicon Carbide Rod Anti-oxidization Anti- CorrosionUS$ 10 - 50MOQ: 10 Pieces