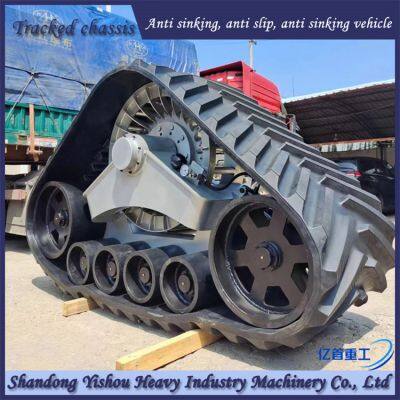

Large Tractor Modified Track Chassis Anti Sinking Half Chain Rail

Turn on the engine water tank drain switch, drain the water, inject an appropriate amount of clean engine oil into the cylinder, and rotate the flywheel several times. Is there any looseness or damage to the components. Loose parts need to be tightened, damaged parts need to be replaced, repaired, and maintained after use

Clean up the accumulated material on the surface. Weeds, straw, dust, and oil on the cutting platform, bridge, grain silo, and outside of the engine should be cleaned thoroughly. Remove the upper screen, lower screen, and tail screen from the screening box, clean the bottom shell of the screening room and the weeds and dust inside the screening box, rinse them with tap water, dry them, and drive them into the hangar.

Remove all triangular tapes, wipe them clean, attach labels, hang them on the walls of the hangar, remove the chains, clean them with diesel, apply engine oil or butter, and store them in a ventilated and dry place.

Add butter to each transmission bearing, and apply oil or butter to friction parts such as the reel, agitator telescopic rod sleeve, tension screw, etc. to prevent rusting. Remove rust from exposed parts and areas where paint has been worn off before repainting

Turn on the engine water tank drain switch, drain the water, inject an appropriate amount of clean engine oil into the cylinder, and rotate the flywheel several times. Is there any looseness or damage to the components. Loose parts need to be tightened, damaged parts need to be replaced, repaired, and maintained after use

Clean up the accumulated material on the surface. Weeds, straw, dust, and oil on the cutting platform, bridge, grain silo, and outside of the engine should be cleaned thoroughly. Remove the upper screen, lower screen, and tail screen from the screening box, clean the bottom shell of the screening room and the weeds and dust inside the screening box, rinse them with tap water, dry them, and drive them into the hangar.

Remove all triangular tapes, wipe them clean, attach labels, hang them on the walls of the hangar, remove the chains, clean them with diesel, apply engine oil or butter, and store them in a ventilated and dry place.

Add butter to each transmission bearing, and apply oil or butter to friction parts such as the reel, agitator telescopic rod sleeve, tension screw, etc. to prevent rusting. Remove rust from exposed parts and areas where paint has been worn off before repainting

Send Inquiry to This Supplier

You May Also Like

-

Tractor Modified With Half Chain Rail to Increase PowerUS$ 2800 - 28000MOQ: 1 Pair

-

Tractor Installation With Half Track Anti Sinking and Anti-skidUS$ 2800 - 28000MOQ: 1 Pair

-

Corn Harvester Modified With Anti Sinking Half Chain Rail Mud Leveling, Stable and ReliableUS$ 2800 - 28000MOQ: 1 Pair

-

Large Harvester Modified With Half Chain Track ChassisUS$ 2800 - 28000MOQ: 1 Pair

-

Crawler Chassis Harvester Modified With Half Chain Rail Anti Slip and Anti SinkingUS$ 2800 - 28000MOQ: 1 Pair

-

What Should I do if the Mud Harvester Gets Stuck?US$ 2800 - 28000MOQ: 1 Pair

-

Large Harvester Modified With Half Chain Rail to Solve the Problem of Mud Sinking VehiclesUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Modification of Tracked Chassis HarvesterUS$ 2800 - 28000MOQ: 1 Pair

-

Tractor Modified With Triangular Track Wheels, Stable and Anti-skid in Swamp TerrainUS$ 2800 - 28000MOQ: 1 Pair

-

High Horsepower Tractor Modified With Triangular Track Wheels, Anti Sinking and Anti-skid on Muddy GroundUS$ 2800 - 28000MOQ: 1 Pair