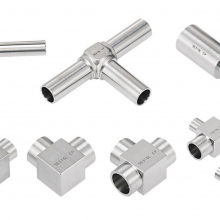

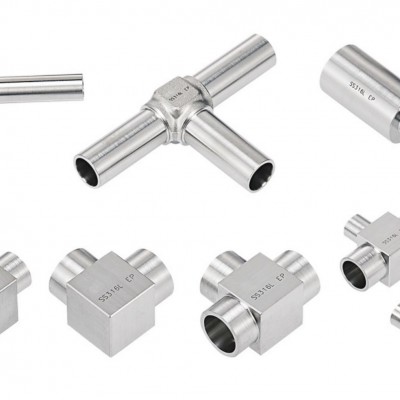

Its ultra clean, high-precision, vacuum high-pressure leak free and ultra long lifespan characteristics are widely used in semiconductor manufacturing, solar energy, nuclear energy, LED, TFT-LCD, petrochemical, biopharmaceutical manufacturing and other fields. Especially in the transportation of ultra clean gases (special gases)

Played a crucial role. MGFS series connectors, customers can choose BA grade and EP grade according to process requirements. According to customer requirements for material cleanliness

We offer three materials to choose from for cleanliness level requirements: 316L, 316L VAR (single V), and 316L VIM+VAR (double V).

Characteristics of the joint

1. Ultra high cleanliness: The average roughness of the standard surface polished on the connecting pipe and joint body can reach Ra 10 µ in (0.25 µ m) and Ra 5 µ in. 2 Excellent sealing performance: Metal face sealing, providing leak free service from vacuum to high pressure range

3. Ultra wide temperature resistance: Using metal gaskets, the maximum temperature resistance can reach 537 ℃ (SS316L gasket)

4. Ultra long service life: The internal thread of the internal threaded nut is treated with silver plating to prevent wear and tear

5. Super strong safety: Each nut end is designed with test holes, which is extremely convenient for leak proof testing after connection

6. Superb spaciousness: disassembly and assembly can be completed in minimal space

Strict production process requirements:

Raw material testing ->joint processing ->mechanical polishing ->repeated cleaning ->electrolytic polishing ->passivation ->rinsing+drying. The final cleaning and packaging are all completed in a clean room, and the clean packaging is delivered to the customer.

Send Inquiry to This Supplier

You May Also Like

-

Micro Variable Diameter Tee Joint RMTNegotiableMOQ: 100 Pieces

-

Micro Four-way Connector MCUNegotiableMOQ: 100 Pieces

-

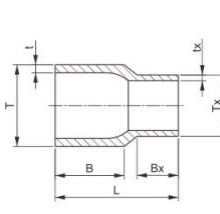

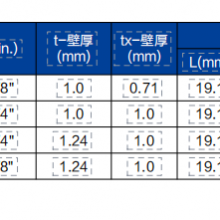

Variable Diameter Straight Joint RUNNegotiableMOQ: 100 Pieces

-

90 Degree Elbow EUNNegotiableMOQ: 100 Pieces

-

Tee Connector TUNNegotiableMOQ: 100 Pieces

-

Variable Diameter Tee Joint RTNNegotiableMOQ: 100 Pieces

-

Four Way Connector CUNNegotiableMOQ: 100 Pieces

-

Micro 3D Tee Connector MTDNegotiableMOQ: 100 Pieces

-

Micro 3D Tee Connector MTDNegotiableMOQ: 100 Pieces

-

Ultra Pure Low-pressure Manual Diaphragm Valve DLMNegotiableMOQ: 100 Pieces