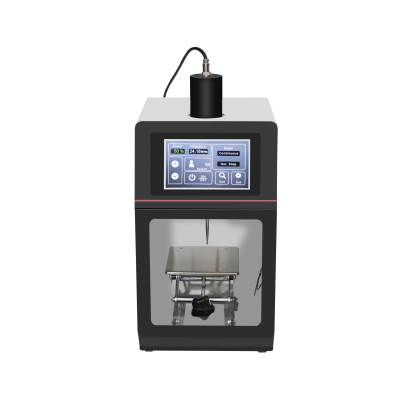

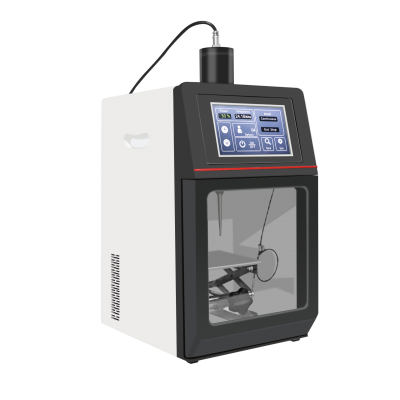

NE-1800Z Ultrasonic Processor

1.Main Applications

Ultrasonic processor, or we can call it ultrasonic cell disruption system,Ultrasonic Cell Crusher, extraction apparatus, dispersing apparatus, homogenizer, or emulsifier. It is one of the common equipment for sample pretreatment in laboratory. It is widely used in the fields below:

Preparation of composite materials (nanomaterial dispersion)

Life sciences (cell disruption and extraction)

Pharmaceutical ( extraction of medicinal herbs and other plants)

Environmental science (extraction of soil organic matter)

Sewage Treatment (COD degradation)

Homogeneous blending (accelerated dissolution, chemical reaction synthesis, oil-water emulsification)

2.Product Features

■Automatic frequency tracking: automatic frequency sweep tracking within 20KHz frequency range;

■ Automatic energy compensation: it can automatically work at the best frequency point and output point according to the fluidity of the sample;

■ Adopt 7-inch color industrial touch screen control, all functions are integrated display;

■ Scientific design: 10 groups of users store settings and can be directly operated on a single machine;

■ Independent continuous pulse mode switch and three modes of continuous, pulse, and timed continuous ultrasound;

■ Exponential ultrasonic probe design far exceeds the output efficiency of traditional probe design and reduces the loss of the horn;

■ The equipment is equipped with a temperature sensor, which can test the temperature of samples in real time;

■ Alarm protection device for sample overload, over temperature and fault automatic.

■ Built-in ultrasonic output display light: ultrasonic output state can be observed in real time.

3.Product technical parameter table

Ultrasonic host parameters

Model # | NE-1800Z |

Power supply | 110V or 220V/50-60Hz |

Ultrasonic power | 1800W |

Nominal frequency | 19-26KHz(Real-time display frequency) |

Timer | 1Min~99H can be setting |

Power regulation | 1%—100%;precision:1% |

Temperature setting | 0—300℃;precision:1℃ |

User program | 10 groups (can be set, can be stored, working status can be viewed in real time) |

Pulse interval time | 1S~60Min can be set and saved |

Operating mode | Pulse、Time、Continuous |

LCD screen | 7-inch color touch screen, resolution: 800×480 |

Operating language | English |

Main interface display parameters

| Ultrasonic output power, frequency, working mode, user group, setting key, equipment operating status, start/stop, equipment operating parameter details key |

Run interface display | Total running time, working time, stop time, user group, overload temperature, power output ratio, working mode, program save key |

Display light

| Built-in ultrasonic output running display light. ultrasonic output state can be observed in real time |

Boundary dimension | 340mm×270mm×479mm |

4.Ultrasonic probe parameters

Standard Configuration of probe | Titanium alloy :TC4 | |

Tip diameter(probe equipped) | Φ18mm | |

Handling capacity | 50-2200ml | |

Cable length | 150cm | |

Optional probe diameters (mm) | Φ10(50~500mL) Φ16(50~1200mL) Φ18(1000~1800mL) | |

5.Instrument Matching List

Ultrasonic host | 1 unit |

Ultrasonic probe | 1 set |

Lifting table, non-slip mat | 1 set |

Temperature sensor | 1 unit |

Power cord | 1 pc |

Cable | 1 pc |

Fuse | 3 pcs |

Weight | 12kg |

6.Interface specification

①power switch ②user group ③setting key ④frequency ⑤power increase

⑥power ratio ⑦power decrease ⑧working mode ⑨equipment operating status

⑩equipment operating parameter details key

7. Operation

7.1 Power supply connection

Before using the user must first connect ultrasonic transducer and ultrasonic generator. Support the sleeve with sound box (also can be supported with bracket or held on sleeve part, but the transducer part can not be touched ), put the head of horn into solution for 10-25 mm. Connect the equipment to power, after the power switch on the right chassis for about 1 seconds, Interface displays as follows(pic.1)

7.2 Program setting

First select the user number, the corresponding user number for setting procedures.

Click "SET" to enter the setting program interface.(pic.2)

Fill in the program number you want to set and press the Enter to complete it.(pic.3)

Direct touch the time program to set, input the corresponding number of time, press OK, you can complete the setting.

After setting the program, click "Save" to SAVE the program. Next time you need to use the program, you can directly select the user number to call up the program set.

8.Level Installation and Removal

1.Install the transformer, put the transducer flat on the work table, hold the wrench 1 with the left hand and reverse jam the aluminum alloy 1 part of the transducer, hold the wrench 2 with the right hand and front jam the transformer 2 part of the transducer, fasten and fix the transducer with the left hand and exert downward force, and clamp the transducer with the right hand and exert downward force. (soft spacer can be used to protect the surface of the transformer when clamping) as shown in the figure below:

①cloth liner ②workbench ③bayonet 1 ④bayonet 2 ⑤Wrench 1

⑥Wrench 2 ⑦probe

2. Remove the amplitude converter, place the transducer flat on the work table, hold the wrench 1 with the left hand and reverse jam the aluminum alloy part 1 of the transducer, hold the wrench 2 with the right hand and front jam the transformer 2 with the left hand, fasten and fix the transducer with downward force, and clamp the transducer with the right hand and upward force. (soft spacer can be used to protect the surface of the transformer when clamping) as shown in the figure below:

Send Inquiry to This Supplier

You May Also Like

-

NE-1500Z Ultrasonic ProcessorNegotiableMOQ: 1 Set

-

Time-of-flight (TOF) Crack Depth Measurement Surface Wave Testing for Crack Detection Digital Ultrasonic Concrete Testing DeviceUS$ 2200 - 2400MOQ: 1 Set

-

Industrial Herb Ultrasonic Essence Extraction Machine Plant Supersonic Wave Extracting Concentration EquipmentNegotiableMOQ: 1

-

Ultrasonic Wave Body MassagerUS$ 300 - 350MOQ: 1 Unit

-

Ultrasonic Vacuum Machine for Ultrasonic Waves Skin CareUS$ 1 - 50MOQ: 1 Set

-

Chargeable Photon Ultrasonic Skincare Machine Ultrasonic WavesNegotiableMOQ: 50 Pieces

-

Photon Ultrasonic Waves Skin Care MachineUS$ 500 - 2,500MOQ: 1 Piece

-

Newest Photon Ultrasonic Waves Skin Care MachineUS$ 1 - 40MOQ: 1 Set

-

Steel Nuts and Bolts Ultrasonic Wave CleanerUS$ 10,000 - 18,000MOQ: 1 Set

-

Machine Ultrasonic Wave Non Woven BagUS$ 0.1 - 0.8MOQ: 5000 Pieces