Professional Industrial Used Aseptic Paper Carton Box Juice Making and Filling Machinery Machine Line

Canned food is a kind of food that can store for a long time after pre-processing,seasoning, filling,vacuum sealing,sterilizing.After many years’ devotion to canned fruit processing line,our company has developed advanced and mature canned fruit processing design and turnkey project.We are aimed at providing the most reasonable processing equipment for customers. The complete canned fruit production line includes pre-processing,filling,exhausting, sealing, sterilizing,cooling cedures.

The first part:

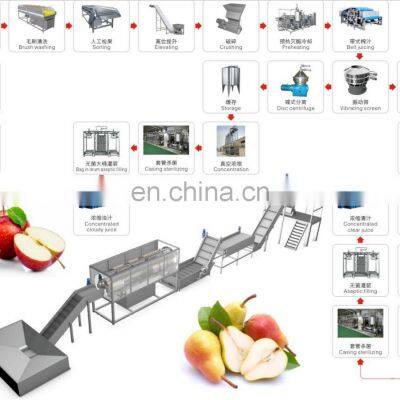

Lifting system, cleaning system, sorting system, crushing system, preheating and inactivating enzyme system, beating system,vacuum concentration system, sterilization system, aseptic big bag filling system

The Second part:

Extraction pump → preparation tank → homogenization → degassing → sterilization machine → can washing machine (bottle) machine →filling machine → capping machine (capping machine) → tunnel spray sterilization machine → drying machine → Inkjet Printer →Packing

Extra step for pineapple juice

|

|

|

|

| Liquid product form : Fruit juice jam processing, fruit wine vinegar enzyme processing, plant extract processing production lines can be roughly divided into the following process sections * Cleaning and picking process section: mainly includes raw material receiving, cleaning, sorting, etc. * Crushing and beating process section: mainly includes crushing of raw materials, enzyme inactivation, beating, etc. * Biochemical refining process section: mainly includes enzymatic hydrolysis, fermentation, filtration, blending, degassing, homogenization, etc. * Sterilization and filling process section: mainly includes UHT sterilization, filling, post-pasteurization, etc.; |

|

| Solid product form Dried fruit processing and fruit powder processing production lines can be roughly divided into the following process sections * Cleaning and picking process section: mainly includes raw material receiving, cleaning, sorting, etc. * Peeling and slicing process section: mainly including stem removal, stem removal, skin removal, core removal, slicing, etc. * Biochemical refining process section: mainly includes blanching, color protection, sugar soaking, drying, etc. * Spray drying powder process: liquid product form - sterilization filling process section - sterilization - spray drying -secondary drying / granulation, etc. |

|

|

|

Send Inquiry to This Supplier

You May Also Like

-

Tomato Ketchup Making Machine With CE ISO CertificateNegotiableMOQ: 1

-

Full Automatic Complete Bib 220l Aseptic Drum Tomato Paste Production Processing PlantNegotiableMOQ: 1

-

Industry Factory Price Tomato Sauce Making Ketchup Processing Machine Tomato Paste PlantNegotiableMOQ: 1

-

Industry Large Tomato Paste Production Line Mini Complete Industrial Concentrate Tomato Paste Processing PlantNegotiableMOQ: 1

-

Factory Genyond Fruit Extraction Juice Pulping Jam Making Equipment Paste Concentration Machine Production Line Processing PlantNegotiableMOQ: 1

-

Automatic Industrial Complete Pineapple Juice Production LineNegotiableMOQ: 1

-

Vertical Stainless Steel Colloid Mill Food Grade Peanut Butter Grinder Laboratory Small Colloid MillNegotiableMOQ: 1

-

Automatic Banana Milk Filling Machine/Fruit Juice Bottling LineNegotiableMOQ: 1

-

Industrial Stainless Steel Fruit Juice Milk Vacuum Degassing Tank Degas Machine Deaerator Degasser EquipmentNegotiableMOQ: 1

-

Fruit Juice/Milk Deaerator MachineNegotiableMOQ: 1