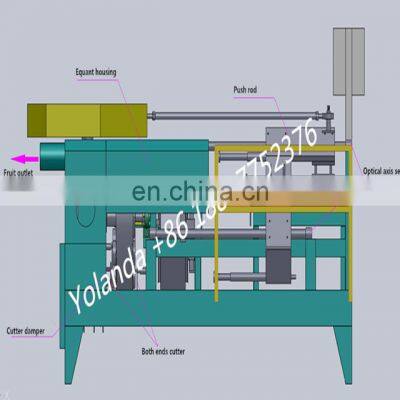

High Quality Pineapple Processing Machine for Peeling Cutting Slicing

Pineapple peeling through the heart machine is through the artificial fruit, using the mechanical principle to peel the meat, cut the ends, heart, fruit, and a series of actions to complete the pineapple processing. The throughput is: 30/min. Models and accessories can be customized according to the model specifications of the fruit.

Automatically cutting both ends of the pineapple, coring, peeling and eradicating the left fruit meat on the peels.

|

Model |

PP-30 |

|

|

Capacity |

20-30pcs/min |

|

|

Material |

Carbon steel + stainless steel |

Fully stainless steel |

|

Power |

2.5kw |

|

|

Dimension |

2600*1500*1600mm |

|

|

Weight |

700kg |

|

Using Scope

This peeling machine is used for peeling skin of fruit , such as pineapple,apple,melon,

watermelon, Papaya, grapefruit, hami melon, taro, mangoe ,etc

Production Features

1.This machine can peel and remove the eye holes at the same time, machine has paring knife, eye knife, robot, set fruit fork, PLC etc

2. The blade of machine can follow the shape of the fruit automatically, the peeling thickness can be adjusted. Before start the machine, choosing suitable blade according to quantity of slicing.

3. Products using thick stainless iron manufacturing, durable.

The first part:

Lifting system, cleaning system, sorting system, crushing system, preheating and inactivating enzyme system, beating system, vacuum concentration system, sterilization system, aseptic big bag filling system

The Second part:

Extraction pump → preparation tank → homogenization → degassing → sterilization machine → can washing machine (bottle) machine → filling machine → capping machine (capping machine) → tunnel spray sterilization machine → drying machine → Inkjet Printer → Packing

Liquid product form

Fruit juice jam processing, fruit wine vinegar enzyme processing, plant extract processing production lines can be roughly divided into the following process sections

1) Cleaning and picking process section: mainly includes raw material receiving, cleaning, sorting, etc.

2) Crushing and beating process section: mainly includes crushing of raw materials, enzyme inactivation, beating, etc.

3) Biochemical refining process section: mainly includes enzymatic hydrolysis, fermentation, filtration, blending, degassing, homogenization, etc.

4) Sterilization and filling process section: mainly includes UHT sterilization, filling, post-pasteurization, etc.;

5) Finished product packaging process section: mainly includes light inspection, drying, labeling, sleeve labeling, coding, packing, sealing, wrapping, palletizing, etc.

Solid product form

Dried fruit processing and fruit powder processing production lines can be roughly divided into the following process sections

1) Cleaning and picking process section: mainly includes raw material receiving, cleaning, sorting, etc.

2) Peeling and slicing process section: mainly including stem removal, stem removal, skin removal, core removal, slicing, etc.

3) Biochemical refining process section: mainly includes blanching, color protection, sugar soaking, drying, etc.

4) Spray drying powder process: liquid product form - sterilization filling process section - sterilization - spray drying - secondary drying / granulation, etc.

5) Finished product packaging process section: mainly including weighing, baggingboxing, labeling, coding, packing, sealing, wrapping, palletizing, etc.

Send Inquiry to This Supplier

You May Also Like

-

Fully Automatic Aseptic Bricks Filling and Packing Machine for Juice BeveragesNegotiableMOQ: 1

-

High Quality 200ml 500ml Aseptic Bricks Filling and Packing Machine for Juice BeveragesNegotiableMOQ: 1

-

Automatic 200ml Carton Bricks Aseptic Filling and Packing MachineNegotiableMOQ: 1

-

Commercial Orange Peeling Machine Vegetables and Fruits Peeler Machine Orange Peeler Machine AutomaticNegotiableMOQ: 1

-

Garlic Splitting MachineNegotiableMOQ: 1

-

Triangle Carton and Fino Pouch Combined Aseptic Neutral Liquid Filling and Packing Machine for Milk, JuiceNegotiableMOQ: 1

-

Frozen French Fries Processing Machine Plant Price for SaleNegotiableMOQ: 1

-

5T per Hour Industrial Automatic Steam Potato Carrot Tomato Peeling MachineNegotiableMOQ: 1

-

Industrial High Pressure Potato Instant Steam Peeling Machine for Frozen French FriesNegotiableMOQ: 1

-

Automatic Commercial Potato Carrot Steam Peeling Machine Auto Industrial Tomato Sweet Tomato Steam Peeler Cheap Price for SaleNegotiableMOQ: 1