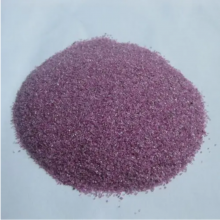

Pink Fused Alumina Gravels Chrome Electrocorundum Grit F40 F46 Abrasive Raw Material

Introduction

Chromium Corundum Raw Materials (also called Chrome Corundum Material), Chromium corundum (Pink Fused Alumina, Pink Fused Aluminium Oxide, Chromium Aluminum Oxide) is a pink / rose abrasive made of high purity alumina and proper amount of chromium oxide in arc furnace. The content of alumina (Al₂O₃) is more than 98%, and there are about 0.7% chromium oxide (Cr₂O₃) and 0.3% Na₂O. Chromium corundum is a kind of excellent abrasive with wide application because of its high hardness, good toughness, good self-sharpness, high cutting finish, low magnetic content, concentrated particle size and pure content.

Chromium corundum is a product made by reducing Cr₂O₃ with pure alumina. it is equivalent to a composite refractory made of pure corundum (or white corundum) melted by adding more than 10% pure Cr₂O₃. Because of the high content of Cr₂O₃ and its binding to corundum matrix, it is called chromium corundum. Chromium corundum has to go through high temperature smelting above 2000°C in the production process, and its composition is more uniform because of its good thermal stability and high temperature chemical stability.

The high density of chromium corundum is the key factor to improve the lining life. After melting, the porosity of the solidified chromium corundum block is small, so the key part of the furnace body is built of chromium corundum, and the gap of the brick is filled with chromium corundum powder and binder.

Features

1) High refractoriness, high softening temperature under load and low creep rate at high temperature;

2) Stability under strong reducing atmosphere;

3) Strong resistance to molten ash corrosion;

4) Higher high temperature strength and erosion resistance;

5) Good thermal shock stability.

Chemical & Physical Index

Item | Chrome-Corundum Granule | Chrome-Corundum Granule | Chrome-Corundum Powder | Chrome-Corundum Powder | Chrome-Corundum Powder |

Al₂O₃ | 78.00% | 85.00% | 78.00% | 85.00% | 99.50% |

Cr₂O₃ | 15.00% | 10.00% | 15.00% | 10.00% | 0.30% |

Na₂O | 0.50% | 0.30% | 0.50% | 0.30% | - |

SiO₂ | 0.30% | 0.20% | 0.30% | 0.20% | - |

Density | 3.55 grm/cc | 3.70 grm/cc | 3.70 grm/cc | 3.70 grm/cc | 3.85 grm/cc |

Bulk density | 1.71 grm/cc | 1.79 grm/cc | 3.1 | 3.1 | 1.86 grm/cc |

hardness | KNOPPS = 2000, MOHS = 9 | KNOPPS = 2000, MOHS = 9 | KNOPPS = 2000, MOHS = 9 | KNOPPS = 2000, MOHS = 9 | KNOPPS = 2000, MOHS = 9 |

melting point | 2,000°C | 2,000°C | 2,000°C | 2,000°C | 2,000°C |

acid reaction | Subject to mild attack by aqua | Subject to mild attack by aqua | Subject to mild attack by aqua | Subject to mild attack by aqua | Subject to mild attack by aqua |

regia and/or Hydrofluic | regia and/or Hydrofluic | regia and/or Hydrofluic | regia and/or Hydrofluic | regia and/or Hydrofluic |

Application :

◆High Temperature Refractory aggregate material

◆Body and vehicle armor

◆Sandblasting

◆Anti-slip

◆Grinding Polishing

◆Coatings

◆Ceramics

◆Abrasives

◆Laminates

◆Filter

◆Electrical insulator

Package

1 ) . In 1MT Big Bag

2 ) . 25KG PP Big Bag In 1MT Big Bag

3 ) . customized packing as required

Sizes

Section Sand Size: 1-0mm 3-1mm 5-3mm 8-5mm

Fine Powder Size: 200Mesh 325Mesh

Grit sand Size: ANSI or FEPA F 8, 10, 12, 14, 16, 20, 24, 30, 36, 46, 54, 60, 70, 80, 90, 100, 120, 150, 180, 220, 240.

Micronized powder: FEPA sized 280, 320, 360, 400, 500, 600, 800, 1000, 1200

Send Inquiry to This Supplier

You May Also Like

-

High Alumina Homogenized Bauxite Compound AggregateUS$ 180 - 330MOQ: 1 Ton

-

95% Al2O3 High Alumina Hollow Sphere Ceramics Balls Refractory Aggregate Raw MaterialsUS$ 900 - 1300MOQ: 1 Ton

-

High Alumina Hollow Sphere Balls Pure Refractory Aluminum Oxide Bubble BallsUS$ 1500 - 1800MOQ: 1 Ton

-

High Purity Alumina Granules Fused Corundum Abrasive Grit Refractory AggregatesUS$ 800 - 1200MOQ: 1 Ton

-

High Alumina Hollow Cenosphere Balls Corundum Hollow Pheres Aluminum Oxide Bubble BallsUS$ 1200 - 1500MOQ: 1 Ton

-

High Purity High Conductive Silica Carbide Aggregate Powder Granules Raw MaterialsUS$ 500 - 710MOQ: 1 Ton

-

Top Grade SiC 99.9% Black Silicon Carbide Powder Aggregate for Abrasive and RefractoriesUS$ 600 - 990MOQ: 1 Ton

-

High Purity SiC Black Silicon Carbide Granules Particles for Abrasive and RefractoriesUS$ 500 - 900MOQ: 1 Ton

-

High Heat Conductivity Silicate Bonded SiC Refractories Silicon Carbide Refractory BricksUS$ 600 - 999MOQ: 1 Ton

-

Professional Fireclay Brick Low Creep Refractory Thermal Insulation Fire Clay BricksUS$ 250 - 350MOQ: 1 Ton