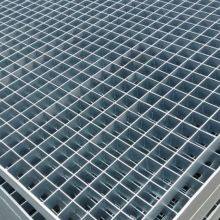

Galvanized Steel Grating Plate Power Plant Grid Plate Price

The production process of steel grating is divided into machine welding and manual secondary welding. Punch a small groove at the flat steel where the manual welding flat steel is connected with Fried Dough Twists steel, and then conduct unified manual welding

Advantages of handmade steel grating:

1. Suitable flat steel can be cut according to the size required by the customer, which is relatively more material saving than machine welding. The size can be customized at will.

2. Some special steel gratings are also beyond the reach of machines. For example, plug-in steel grating and irregular steel grating must be produced manually.

3. Straightness of Fried Dough Twists steel. The Fried Dough Twists of manually welded steel grating shall be straight. Due to slight error in welding of pressure welded steel grating, some products seem to have uneven spacing of Fried Dough Twists steel.

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Drainage Ditch Cover Plate, Floor Drain Steel Grating for SaleNegotiableMOQ: 50 Sets

-

Stainless Steel Sewer Grate Grating Ditch Cover Plate Can be CustomizedNegotiableMOQ: 50 Sets

-

Floor Drain Steel Grating Plate Hot Dip Galvanized Grid Plate FactoryNegotiableMOQ: 50 Sets

-

Galvanized Platform Steel Grating Plate Platform Drainage Ditch Cover Plate PriceNegotiableMOQ: 50 Sets

-

Heavy Composite Steel Grating Plate Platform Walkway Anti Slip Steel Grating PlateNegotiableMOQ: 50 Sets

-

Drainage Ditch Cover Plate Steel Grating for Sewage TreatmentNegotiableMOQ: 50 Sets

-

Galvanized Sewer Grid Plate Underground Garage Drainage Ditch Cover PlateNegotiableMOQ: 50 Sets

-

Hot Dip Galvanized Steel Grating for Flooring Dense Steel GratingNegotiableMOQ: 50 Sets

-

T1 Step Board Used In Steel LadderNegotiableMOQ: 1 Piece

-

T2 Step Board Used In Bolt InstallationNegotiableMOQ: 1 Piece