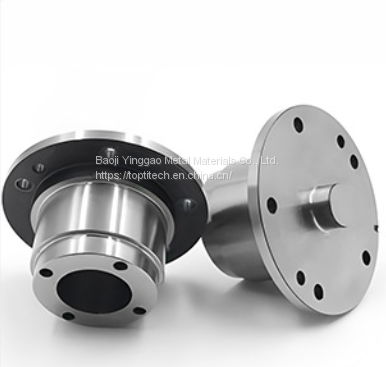

The Pure Titanium Flange

Due to the excellent corrosion resistance of titanium material, the pure titanium flange is much used for connecting the tube ends of the petrochemical project. It is also useful in equipment exits and entrances to connect the two devices.

Titanium flange has high strength and corrosion resistance can maintain excellent strength at higher temperatures and is known for its ductility and weldability, titanium is usually used for high temperature and high-pressure service but lightweight applications such as components for the aerospace industry (airframes) and state-of-the-art equipment for the military. It also has excellent corrosion resistance in marine and chloride applications.

Product parameters

Material: CP titanium, titanium alloy

Grade: Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 etc

Size: DN10~DN2000

Standard: ANSI B16.5, ANSI B16.47

Pressure: 0.25MPa~32MPa

Technology: Forging, Machining, Welding

Surface: RF, FF, MFM, TG, RJ etc

Product Features

1. High fortitude

Titanium has a density of 4.51 grams per cubic centimeter, which is just 60% that of steel. Pure titanium has a density similar to ordinary steel, and some high-strength titanium alloys are stronger than several alloy structural steels.

2. Extreme heat intensity

Titanium alloy materials can still keep the needed strength under medium temperature circumstances, and can develop and work for a long time at 450-500 °C.

3. Good corrosion resistance

The corrosion resistance of titanium alloy is much better than that of stainless steel, such as pitting corrosion, acid corrosion, stress corrosion, alkali, chloride, chlorine, nitric acid, sulfuric acid, etc.

4. Good low temperature performance

The mechanical properties of titanium alloys can be maintained at low and ultra-low temperatures. Ta7 titanium alloy is a titanium alloy with excellent low-temperature performance and extremely low content of interstitial elements. It can maintain a certain degree of plasticity at a temperature of -253°C.

Product Type

Slip-on Neck Flange (SO)

Welding neck flange (WN)

Socket welding flange (SW)

Threaded flange (Th)

Lapped joint flange (LJF)

Blind flange (BL(s))

Applications

Titanium flanges are known for their high strength and lightweight, making them excellent for naval applications as well as oil and gas offshore drilling equipment. They're also frequently employed in chemical processing systems that require chlorine and chlorine compounds. While titanium flanges are known for their lightweight strength, zirconium flanges are known for their exceptional corrosion resistance in hostile chemical conditions such as hydrochloric acid, sulfuric acid, formic acid, nitric acid, and acetic acid. Typical pipe flange Among the applications are:

Chemical processing, which includes polymer manufacturing

Production of pulp and paper

Engineering in the sea

Offshore drilling rigs for oil and gas

Send Inquiry to This Supplier

You May Also Like

-

10um Titanium Anode PTL GDL for PEM/PEMFCUS$ 5 - 12.9MOQ: 1 Piece

-

30mesh Platinum Coated Titanium Anode Mesh ScreenUS$ 6 - 12MOQ: 10 Pieces

-

Titanium SpongeUS$ 5 - 9MOQ: 2 Tons

-

0.01mm Titanium FoilUS$ 6 - 8MOQ: 1 Kilogram

-

Gr5 Titanium Scrap Turnings for Ferro TitaniumUS$ 4.6 - 5.2MOQ: 5 Tons

-

Customized Standard Gr1 Titanium Flange ManufacturerUS$ 5 - 30MOQ: 5 Pieces

-

2mm GR1 Seamless Titanium Capillary Tube for MedicalUS$ 6 - 15MOQ: 5 Pieces

-

Titanium Bipolar Electrolyser Plate for Fuel CellUS$ 5 - 20MOQ: 5 Pieces

-

Titanium Electrodes With Flow ChannelsUS$ 5 - 25MOQ: 5 Pieces

-

Titanium Pipe for Exhaust and DownpipeUS$ 5 - 9MOQ: 5 Pieces