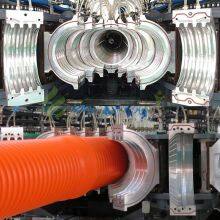

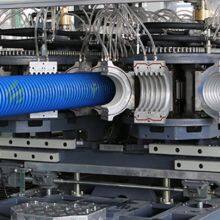

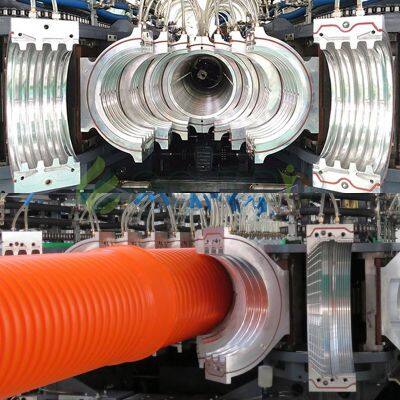

Feature of Double wall corrugated pipe production line:

1. Horizontal structure, closed loop water cooling system.

2. Special material aluminum alloy moulds, easier and faster moulds replacement, no need to disassemble water tubes.

3. Pressure water-cooling for mould blocks greatly increase the production speed; the maximum speed is 1-6.24m/min.

4. Low energy consumption help to cut production cost.

5. Efficient vacuum system for forming perfect pipes.

6. Mould block temperature control system helps to optimize the pipe quality both appearance and inside.

7. Easy and quick changeover between different sizes of moulds.

8. The complete extrusion line runs full-automatically.

9. Corrugator and extruders are synchronously controlled.

10. Harden treated screw and barrels for longer life span and durability.

11. Remote Service is available.

Note: Products canbe customized according to customers' requirements.

Product advantage of bellows production line:

Extruder:The extruders use buffer forced feeding section, the power consumption of the main drive motors is reduced by about 30%.

Die head:Optimized design of double layer die head, inner and outer wall thickness and wall deviation adjustment is very stable and convenient.

Corrugator:The patented closed loop direct water recycled cooling system, changing moulds no need to disassemble water tubes; No platform design, different specifications of the moulds have same center height.

Cutter:The precise trigger device ensures continuously precision cutting; Equipped with dual hydraulic system, symmetrical center, smooth operation.

Mould:The optimized cooling cavity wall ensures the maximum cooling cross-sectional area, so that the cooling water has enough contact surface

with the moulds,and the cooling efficiency is high.

Send Inquiry to This Supplier

You May Also Like

-

PE Layflat Hose (with Fiber) Production LineUS$ 130000 - 150000MOQ: 1 Set

-

1109910-Q485 Rear-Mounted Intake Pipe Process Assembly for FAW J6 Truck - OEM Production Line SpecUS$ 5.5 - 50MOQ: 1 Piece

-

Complete Production Line for BW-II Double-Wall Corrugated PipesNegotiableMOQ: 1 Set

-

Corrugated Board Production LineUS$ 20,000 - 30,000MOQ: 1 Set

-

Corrugated Paper Board Production LineUS$ 540 - 690MOQ: 15 Tons

-

Pvc Single Wall Corrugated Pipe Making Machine Flat Yarn Making Machine for Woven Bag Production LineUS$ 8,500 - 8,500MOQ: 1 Set

-

Pipe Production LineNegotiableMOQ: 1 Set

-

China Supplier Corrugated Cardboard Production Line, Duplex Cardboard Production LineUS$ 200,000 - 280,000MOQ: 1 Set

-

Automatic Corrugated Carton Waxdip Production LineUS$ 1 - 1MOQ: 1 Set

-

Corrugated Paper Production Line (waste Paper)US$ 40,000 - 500,000MOQ: 1 Set