Number of control axes | Maximum number of control axes: 6 axes |

Maximum number of linkage axes: 6 axes (linear interpolation) | |

Maximum number of honing shafts: 2 axes | |

Coordinate size | Position command range: ± 9999999999x minimum input unit |

Absolute incremental programming 、Linear axis | |

Preparation function | Including quick positioning, interpolation, honing station positioning, sentence macro instruction, macro program call, jump,cycle instruction, etc |

Feed function | Fast moving speed: 0 mm / min ~ 60000 mm / min |

Fast magnification: F0, 25%, 50% and 100% four levels of real-time adjustment | |

Cutting feed rate: 0mm / min-30000 mm / min | |

Feed rate: 0 ~ 150%, 16 levels in total, real-time adjustment | |

Fast moving acceleration and deceleration: linear type; Cutting feed acceleration and deceleration: exponential type and linear type; The starting speed, ending speed and acceleration and deceleration time of acceleration and deceleration are set by parameters | |

Spindle function | Spindle speed: it can be given by s code or PLC signal, and the speed range is 0RPM ~ 999rpm |

Spindle magnification: 50% - 120%, a total of 8 levels of real-time repair and adjustment | |

2 channels of 0V ~ 10V analog voltage output, and the analog voltage output can be expanded | |

2-way spindle encoder feedback, and the number of spindle encoder lines can be set | |

Honing control function | Honing station positioning |

Constant pressure control and pressure feedback monitoring of grinding head sand bar | |

Reciprocating control of honing shaft | |

Multi process honing control settings | |

Honing database function | |

Honing reversing control | |

Honing process status display | |

Anilox angle control | |

Synchronous control of double honing shafts | |

Auxiliary function | Special m codes (M00, M01, M02, M30, M98, M99), and other m codes are defined by PLC |

PLC function | Two level PLC program, 5000 steps at most, and the refresh cycle of level 1 program is 8ms |

13 basic commands and 31 functional commands | |

PLC program online display and real-time monitoring; Support PLC warning and PLC alarm | |

Multiple PLC programs can be stored, and the currently running PLC program is selected by parameters | |

Basic I / O: 41 inputs 36 outputs | |

Expandable serial O unit (optional) IOA-02T: 40 point input, 24 point output, 8-Channel analog voltage output and 4-channel analog voltage input | |

Program storage and editing | Program capacity: 40m, 10000 programs (including subroutines and macro programs) |

Editing method: full screen editing | |

Editing functions: program / program segment word retrieval, modification, deletion, copy and paste | |

MD allows you to input and run 8 program segments | |

It supports macro program subroutine calling and allows 4-fold subroutine nesting | |

Calculator | |

Program check function | Idle operation, machine tool lock, auxiliary function lock, single section operation |

Simplify programming functions | Declarative macroinstruction programming |

Reverse clearance compensation: 0mm-2mm, and the reverse clearance compensation mode and frequency are set by parameters | |

Memory pitch error compensation: a total of 1024 compensation points, and the number of compensation points of each axis is set | |

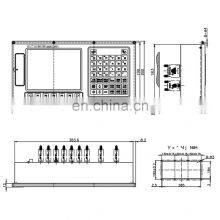

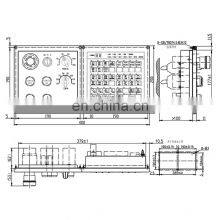

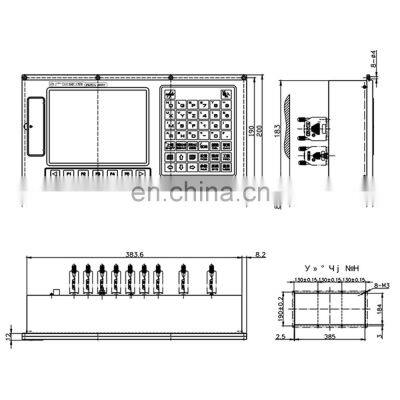

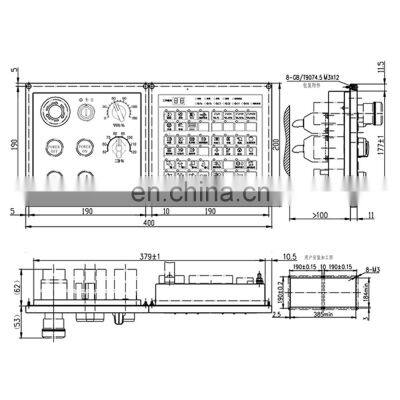

interface | 8.4-inch true color LCD, 7 soft function keys |

Support Chinese, English and other languages | |

Location, procedure, engineering, alarm, parameter, setting, diagnosis, ladder diagram | |

Operation management | Operation mode: edit, automatic, input, mechanical zero return, hand pulse / single step, manual |

Level 6 operation authority management | |

32 time limited shutdown | |

Program switch, parameter switch | |

Communication function | USB: USB disk file operation, direct processing of USB disk files, and support PLC program and system software USB disk upgrade |

RS232: bidirectional transmission of part programs, parameters and other files, supporting PLC program update | |

Safety function | Emergency stop, hardware travel limit, software travel check, data backup and recovery |

Electrical interface | 6 control axes (including CS axis), 2 analog voltage outputs, 2 encoder feedback inputs, 1 electronic hand pulse input (supporting handheld unit), 1 RS232, 1 USB-H, 61 inputs and 44 outputs |

● 6 feed axes, 2 analog spindles |

● synchronous honing with double honing shafts |

● honing process database function |

● on line measurement of measuring instrument |

● constant pressure control / quantitative control of sand bar expansion and contraction |

● precise control of honing reciprocating reversing |

● honing process status display |

● multi axis honing station customization |

● support seamless access of automatic line |

Synchronous honing with double honing shafts

Custom multi axis station

Multiple honing process modes

Automatic honing

Honing process database

Standard honing CNC control format

Honing process status display

Convenient and flexible PLC

Multiple time limited shutdown function

A: Yes,we can customized manufacturing according to customer's requirment. We support to OEM your own company display interface and logo.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to quantity.10-20 days if customized manufacturing.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample with sample price.

Q: What is your terms of payment ?

A: Payment<=2000USD, 100% in advance. Payment>=1000USD, 70% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below

Send Inquiry to This Supplier

You May Also Like

-

CNC Lathe Machining Machinery Rotating Shaft Stainless Steel SpindleNegotiableMOQ: 1 Set

-

Best Price Cnc System Unit Screen Display A02B-0309-B502 oi mf Fanuc ControlNegotiableMOQ: 1

-

12PC High Carbon Steel Metal Blade Offset Thickness Gauge ToolUS$ 1 - 30MOQ: 600 Pieces

-

Tungsten Carbide Insert for CNC MachineUS$ 1 - 1.5MOQ: 1 Kilogram

-

Ice Storing BoxNegotiableMOQ: 1

-

The High Quality Probe From China Machine Tool ProbeUS$ 50 - 100MOQ: 1 Set

-

Bag Closing Machine Spare PartsNegotiableMOQ: 1

-

Antistatic Basin of Pure Aluminium,,garden Tools,hand Tools,power Tools,ISO9001,UKASUS$ 10.83 - 38.33MOQ: 2 Pieces

-

21Spindles/11Spindles Drilling Head Noise Aborsbing BoardNegotiableMOQ: 3 Pieces

-

Mini Electric Hand Drill Holder Suitable For Electric Drill Factory Direct Sale Good Price In StockUS$ 1 - 5MOQ: 10 Pieces