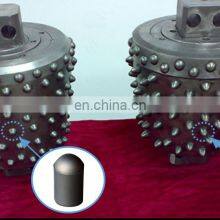

Factory Price Titanium Carbide Rod for Dril Bits on Stone Jaw Crusher

1. Product Introduction

Grade | Density (g/cm3) | Hardness(HRC) | TRS (Mpa) | Porosity | Abrasion test | |||

Annealing | Hardening | |||||||

GT35 | 6.42~6.55 | ≤48 | ≥68 | ≥1400 | A04 B04 | - | √ | |

TM52 | 6.12~6.25 | sintered state: HRC≥60 | ≥1500 | A04 B04 | 7.2 | × | ||

Grade | Elastic modulus (×102kg/cm2) | Specific resistivity (Ωmm2/m) | Coercive force(HC) | Impact toughness (J/cm2) | Thermal expansion Coefficient(×10-6/ºC) | ||||||

Annealing | Hardening | Annealing | Hardening | Temperature | a | ||||||

GT35 | 306 | 298 | 0.812 | ≥3.5 | 68 | ≥3.5 | 20~200 20~700 | 8.43 11.83 | |||

TM52 | - | - | - | - | - | - | 20~200 20~700 | 9.16 11.13 | |||

Samples: by vacuum plastic bag firstly, then by Carton.

Productions: by steel drums, then packed by pallet.

2. Shipping Method

By international express(DHL,FEDEX,TNT or others) / by sea / by air

Zhuzhou Hastion High-tech Materials Co., Ltd.(short for HASTION) is located in Yanling Small and Medium Enterprise Pioneer Park in Zhuzhou City, Hunan Province, which is covering an area of 60,000 square meters and a planned factory area of 50,000 square meters. Now HASTION have 2 different productions lines, one is the raw material metal compound and elemental powder(TiC/Cr3C2/VC/NbC/ZrC/HfC/(W,Ti)C/(Ta,Nb)C and so on), the other one is the titanium carbide cermet rod/insert/plate/customized shape/guide roller and so on(belong to the steel-bonded cemented carbide), until now our products have been sold to many countries, like the Turkey, Belgium, Australia, Japan, Korea, Vietnam, India, Pakistan, Thailand and etc.

HASTION has passed the ISO9001:2008 international quality system authentication. we are well equipped with the high-level machines for production and inspection.until now HASTION has total over 600tons annual production capacity(TiC rod: 120-180tons; metal powder: 400-450tons), also our prodution scale is still increasing.

We are based in Hunan, China, start from 2011,sell to Domestic Market(11.11%),South Asia(11.11%),Southern Europe(11.11%),Central America(11.11%),Eastern Asia(11.11%),Southeast Asia(11.11%),Eastern Europe(11.11%),South America(11.11%),North America(11.11%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel-bonded cemented carbide,carbide ceramic tile cutting,carbide rods,Carbide glass cutting wheel,Cermet rods

4. why should you buy from us not from other suppliers?

Our factory in yanling, Zhuzhou of Carbide centralized place, occupies an area of 50 acres of land. Langfeng own excellent R&D team, responsible for the design of the products, R&D and quality control, have achieved a number of invention patents already.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,Express Delivery;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union;

Language Spoken:English,Chinese

Send Inquiry to This Supplier

You May Also Like

-

Gr2 Titanium Sheet Gr5 Titanium Plate for Medical Customized Titanium PlateNegotiableMOQ: 1 Ton

-

Titanium Alloy TA2 Bright Bar, TA3 Round Bar, High-strength Titanium BarNegotiableMOQ: 1 Ton

-

High Quality ASTM B348 Gr2 Gr5 Forged Round Titanium Bar for SaleUS$ 2,500 - 2,500MOQ: 3000 Tons

-

Cooling System Stainless Steel Tube Bending Heat ExchangerUS$ 100 - 100,000MOQ: 1 Set

-

Copper Sheet Metal Stamping Blanks for Jewelry With Punching / GrindingNegotiableMOQ: 1 Set

-

CNC Components Of Telecommunication System , Aluminum Shafts Rapid PrototypesNegotiableMOQ: 1 Set

-

Customize 6063 6061 Aluminum Auto Brake Pedal Vehicle Foot Treadle Cover PadNegotiableMOQ: 1 Set

-

Window Cleaning Suspended Working Platform Safety ZLP 630 With Hoist LTD6.3NegotiableMOQ: 1 Set

-

High Precision Adjustable Permanent Injection Molded Magnet With NdFeB + PPSUS$ 0.1 - 2MOQ: 1 Set

-

Elevator Decoration , Two Speed Center Opening Door For ElevatorNegotiableMOQ: 1 Set