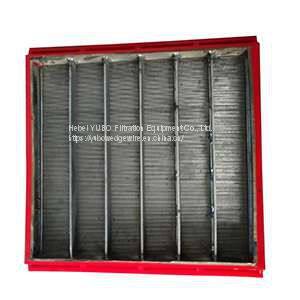

The mine dewatering screen panel is suitable for screening various minerals. Like iron ore, coal, heavy minerals, base metals, ores, diamonds, etc.

Typically constructed of polyurethane wedge wire screens for excellent separation efficiency and minimal material loss. Improve wear life in harsh operating conditions.

Features of Mining screen for filtration

Low Headroom - only 1.1 metres (44") tall for the 900mm arc length unit.

Energy Efficient - operates with no moving parts and with no energy input.

Space Efficient - treats up to 122 litres per second per square metre of floor space.

Quiet Operation - no moving parts means no mechanical or electrical vibrations.

Accurate Sizing - can be used for sizing solid particles down to 0.2mm (0.008").

Low Maintenance - the profile wire screen resists clogging by near-size particles, and the all-stainless steel construction ensures a long, corrosion-free installation.

Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools.

If you need our wedge wire mine dewatering screens, we provide OEM and custom services for the mining industry! Contact us: sales@ubowire.com Tel: 86 311 85955658

Send Inquiry to This Supplier

You May Also Like

-

Slurry Thickener Custom DesignUS$ 1 - 999MOQ: 1 Set

-

Wedge Wire Coal Vibratory SieveUS$ 1 - 200MOQ: 1 Set

-

Cylindrical Sintered Stainless Steel CartridgeUS$ 5 - 200MOQ: 10 Sets

-

Wedge Wire Rundown ScreensUS$ 404 - 420MOQ: 1 Set

-

Ion Exchanger Header Lateral Distributor/Wedge Wire CollectorUS$ 400 - 500MOQ: 1 Set

-

Industrial Stainless Steel Cartridge Strainer Basket Type FilterUS$ 1.5 - 3.5MOQ: 1 Set

-

Filter Housing and Solution for Gas FiltrationNegotiableMOQ: 1 Set

-

Screen Basket for Paper MakingUS$ 1 - 200MOQ: 1 Set

-

Stainless Steel Screen Nozzles-wedge Wire ProductsUS$ 1 - 50MOQ: 10 Sets

-

Ion Exchange Nozzles for Intermediate PlateUS$ 1 - 10MOQ: 10 Sets