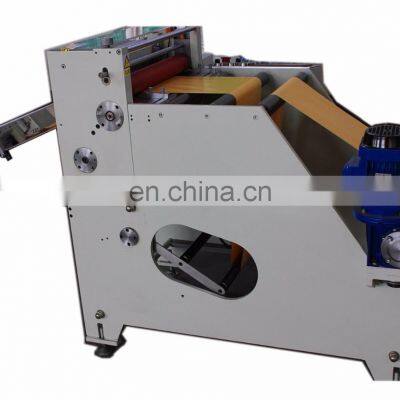

High Precision PLC Servo Control Max Working Width 500mm Paper Roll to Sheet Cutting Machine

360mm automatic paper roll to sheet cutting machine FUNCTIONAL CHARACTERSTICS This machine employs servo motor to feed material, import PLC touch screen operation to set any length, quantity, speed and finish singleness cutting , equipped with automatic unwinding system and air shaft, which will be easy to load and unload. Purpose It is applicable for the cutting of PVC film, insulation sheet, Mylar, foam, industrial tape, rubber sheets, electronic tape and various inch setting, entirely broken and partially broken electronic materials. | ||

Item No | DP-360 |

PRICE shipping term | (FOB Shanghai) |

Max Feeding Width ( mm ) | 360 |

Main Engineer Power ( w ) | 750 |

Speed ( m/m ) | 120 |

Size ( mm ) | 1150*1100*1120 |

Weight ( kg ) | 350 |

Precision ( mm ) | ±0.10 |

Power | 380V 50HZ |

Shaft diameter | 3 inch / 76mm |

unwinding paper diameter | 600mm max (unwind like below) |

DELTA Servo motor control ---more precision then Stepper motor control , so we already Eliminated stepper motor machine

PLC ----- use famous brand Mitsubishi which you will easily maintenance in your local place

Machine body ----- 16mm thickness steel wall for 360mm , it is very solid that to make sure machine stable when

running

it is whole part of steel sheets , not welding together

PULLING ROLLER ---- Thick PU rubber coated and won't scratch the material

Guiding roller ------- Aluminum shaft be polished and hard anodized , very smooth and never harm material

Cutting Blade ----SKD11 material to make sure the cutter use very very long time and cutting material perfect edge

at cutting part

Korea company made

Cutting motor ------------- Taiwan Tonglee gear motor

Safety cover ---- have safety cover at cutting blade , and sensor at it , no cover will not work , to protect the operator safety

12 month electronic parts guarantee after machine arrived your place

machine are use famous brand of electric parts which are easy to maintenance

1, material name : | |

2, material roll diameter : | |

3, material roll width : | |

4, material roll weight : | |

5, maximum and minimum length required to cut |

Send Inquiry to This Supplier

You May Also Like

-

DP-360 Foam Conductive Cloth Sheet CutterNegotiableMOQ: 1

-

XY Axis Fully Automatic High Speed Roll to Sheet Paper Trimmer Slitting Machine Jumbo Roll Paper Cutting MachinesNegotiableMOQ: 1

-

Foam Kiss Cut With Slitting Function Automatic Roll Paper Cross Cutting MachineNegotiableMOQ: 1

-

High Speed Automatic Roll Paper Label Cutting Machine With Slitting Function Max Working Width 500mmNegotiableMOQ: 1

-

Adhesive EVA Rubber Foam Tape Kiss Cutting MachineNegotiableMOQ: 1

-

Full Automatic Paper Roll To Sheet Cross Cutting MachineNegotiableMOQ: 1

-

European Quality Automatic Roll To Sheet Cutting Machine Nonwoven Fabric Roll To Sheet Cutting Machine Roll Material CutterNegotiableMOQ: 1

-

Roll to Sheet Cutting Machine for Aluminum Foil, Paper and Non Woven FabricNegotiableMOQ: 1

-

High Quality Paper Sheeting Cross Cutting Machine With Slitting EPC PLC Stacker PriceNegotiableMOQ: 1

-

Non Woven Fabric Roll To Sheet Cutting Paper Roll CutterNegotiableMOQ: 1