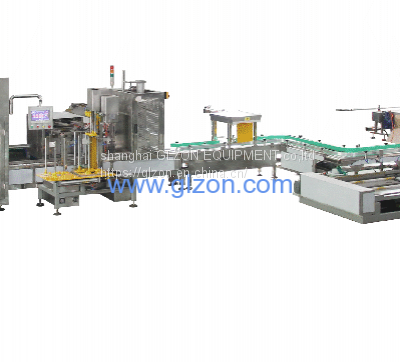

Equipment composition:

1. The complete set of equipment is a mechatronic product composed of bucket system, filling system, weighing system, capping system, pallet supply system, palletizing system, electrical control, pneumatic control, vacuum system, rack, etc.

2. Adopting the technology of Shanghai Guangzhi Group Headquarters, the measurement accuracy is high and it is not affected by materials.

3. On-line display of weighing value

4. Two filling methods: net weight and gross weight

5. Fast/slow filling speed, fast feeding to ensure output, slow feeding to ensure accuracy;

6. The filling weight and other weight parameters can be set arbitrarily within the range of filling quantity adjustment.

7. The filler inlet is DN80 or DN50.

The material buffer hopper has a volume of 300L and is made of SUS304 or 316L stainless steel.

8. Filling head and pipeline adopt quick-loading structure, which is convenient for cleaning.

9. Optional distance between the plane of the conveying roller table and the ground: 500mm 750mm.

10. Automatic barrel sorting and barrel taking equipment is adopted, which accelerates the conveying speed.

Full-automatic barrel loading system: The full-automatic filling machine adopts full-automatic production from the barrel taking and using link. It only needs to put the barrels of the same specification and model in the designated position neatly. The professional manipulator will accurately take out one packaging barrel at a time, and transport the packaging barrels to the bottom of the filling machine through the power track.

10.1 barrel sorting speed: 500-700 barrels per hour

0.2 overall dimensions: 6000×1900×1800mm

10.3 weight: 350kg

11. The weighing filling system is adopted, and the weighing value is displayed immediately.

Full-automatic filling system: The full-automatic filling device is equipped with an automatic meter, which will directly fill the materials into the delivered packaging barrel according to the preset standard through the quantity set by the filling nozzle. The whole process is accurate and fast, which will not cause waste of materials and environmental pollution. The packed drums will be transported to the next link through the power track.

1.1 Filling speed: 500-700 barrels per hour.

1.2 overall dimensions: 1500×1800×2600mm

1.3 weight: 850kg

12. Automatic capping, capping and sealing one by one.

Capping machine products are mainly used for opening barrels, coating barrels, lubricating oil barrels, packaging barrels, paint barrels and portable barrels (convenient barrels) series: the necessary special tools for capping standard barrels of 4 liters, 5 liters, 10 liters, 12 liters, 18 liters, 20 liters and 30 liters. Widely used in barrel making, can making, lubricating oil, coating, chemical industry, petroleum, grain and oil, and other essential supplies for liquid packaging industries.

Capping machine is an important part of the production line, which covers the heavy barrels. Capping machine covers the heavy barrels twice to ensure the tightness of the capping and the smoothness of the capping.

13. Automatic stacking and placing in tray.

Full-automatic palletizing system: the packaging barrels filled with materials by the full-automatic filling machine are sealed and packaged, and then transferred to the automatic stacker. Through the professional manipulator, the automatic stacker accurately sucks the packaging barrels full of materials and places them in the set tray. When the number of buckets in the tray reaches the specified number, the manipulator will automatically transport the tray with the buckets placed to the specified position. This technology can not only save the labor cost by more than 80%, reduce man-made waste and environmental pollution, but also accelerate the production speed, making the whole filling process easier and more professional.

13.1 Stacking speed: 500-700 barrels per hour

13.2 overall dimensions: 7000×4000×2200mm

13.3 weight: 1200kg

14.4 Tray size 1200×1200×150 (can be customized)

15. all parts in contact with the materials are made of SUS304 or 316L stainless steel, and the rest parts are made of carbon steel by plastic spraying, which has corrosion resistance.

20L vat weighing filling machine (CFM-20L)

1. Filling method: filling on the liquid surface (top filling).

2. Control mode: The filling mode is set manually and controlled by microswitch.

3. Conveying mode: roller table unpowered conveyor belt.

4. It has the function of digital display of filling quantity, and can complete the setting of various filling quantities.

5. It has the function of automatic peeling and filling by net weight.

6. It has the function of vacuum pumping back to prevent dripping.

7. It has manual and automatic (microswitch control) functions of control system.

8. It has fast and slow dual-speed control function to prevent splashing.

9. It has emergency treatment functions such as misoperation prevention and power failure protection.

10. The pipeline through which the liquid flows is made of stainless steel 304.

11. Automatic capping, capping and palletizing.

Send Inquiry to This Supplier

You May Also Like

-

GZM-1C Tracking Capping MachineNegotiableMOQ: 10 Bags

-

GZM-1L Single-head Capping MachineNegotiableMOQ: 10 Bags

-

GZM-20L Automatic Directional Capping Machine for Wide-mouth BarrelNegotiableMOQ: 10 Bags

-

GZM-5000 Piston Filling MachineNegotiableMOQ: 10 Bags

-

GZM-4000 Weighing Filling MachineNegotiableMOQ: 10 Bags

-

25-liter Automatic Matching and Capping Weighing Filling MachineNegotiableMOQ: 10 Bags

-

25-liter Automatic Square Barrel Filling, Capping and Labeling Production LineNegotiableMOQ: 10 Bags

-

GZM-30KMS Filling MachineNegotiableMOQ: 10 Bags

-

Gzm-400t Aluminum Foil SealerNegotiableMOQ: 10 Bags

-

Gzm-200l-2 Load Shifting PalletizerNegotiableMOQ: 10 Bags